Improved heat integration coal-fired power plant decarbonization system and method

A coal-fired power station, heat integration technology, applied in separation methods, chemical instruments and methods, air quality improvement and other directions, can solve problems such as inability to use heat reasonably, power generation efficiency decline, normal operation impact of steam turbine low-pressure cylinders, etc., to achieve high comprehensive Effectiveness of energy utilization efficiency and technical and economic performance, restraining the decline of power generation efficiency, and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

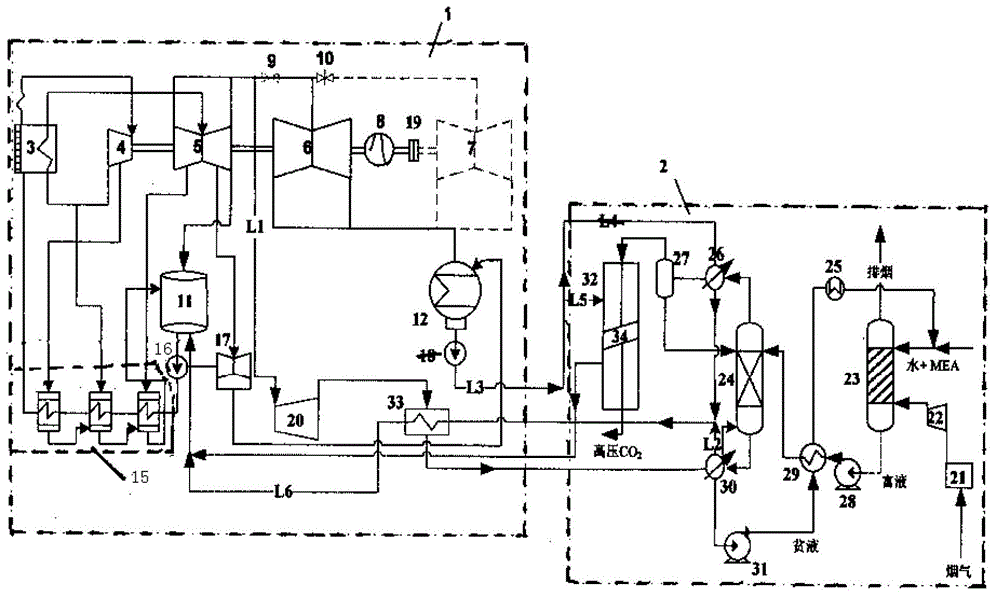

[0012] An improved heat-integrated coal-fired power plant decarbonization system and decarbonization method of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 shown. The system is mainly composed of steam turbine power generation unit 1, CO 2 The capture unit 2 is composed of two parts, among which,

[0014] The steam turbine generating unit 1 is a small steam turbine 20 connected to the exhaust steam of the medium pressure cylinder 5 through the L1 pipeline, and the exhaust steam of the small steam turbine 20 is connected with the CO through the heat exchanger 33 2 The inlet of the reboiler 30 of the capture unit 2 is connected, the outlet of the reboiler 30 is connected with the outlet of the cooler 26 at the top of the desorption tower 24 through the L2 pipeline, and the outlet of the top cooler 26 is connected to the cold inlet of the heat exchanger 33, and the outlet of the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com