A kind of bioactive multilayer composite ceramic microsphere material, preparation method and application

A composite ceramic and biologically active technology, applied in medical science, prostheses, etc., can solve problems such as long time for complete bone repair, insufficient coordination and matching of bone damage speed, and limited technical means, and achieve excellent biocompatibility, effective Favorable effect on cell migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: [Composite ceramic microspheres with zinc-doped β-calcium silicate as the core layer and strontium-doped β-tricalcium phosphate as the shell layer]

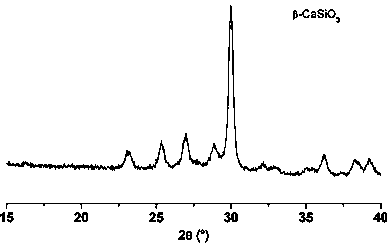

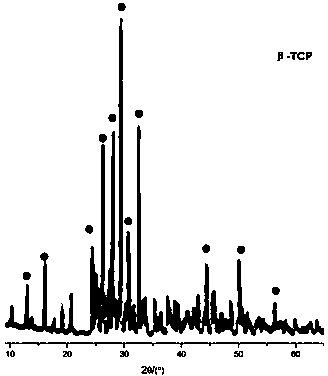

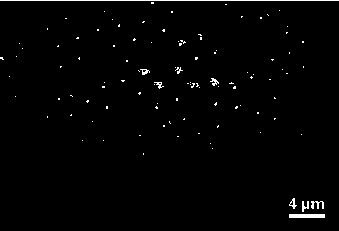

[0040] 1) Add 500 mL of 0.275 mol / L CaCl 2 , 0.025 mol / L SrCl 2 The pH value of the aqueous solution was adjusted to 10.8, and then the solution was added dropwise to 0.2 mol / L (NH 4 ) 2 HPO 4 In the aqueous solution of inorganic salt, continue to stir for 30 minutes after the dropwise addition is completed, then filter the reaction deposit, wash with deionized water for 4 times, and then wash with absolute ethanol for 2 times, 80 o C drying, after 850 o C for 3 hours and ball milling for 3 hours to obtain strontium-doped β-tricalcium phosphate powder with a particle size of 2-6 μm. After X-ray diffraction test, the diffraction peaks of the obtained powder (such as figure 1 (shown) is consistent with the diffraction peak of β-tricalcium phosphate, indicating that the phase of the synthesized powder is β-t...

Embodiment 2

[0043] Example 2: [Composite ceramic microspheres with magnesium-doped β-tricalcium phosphate as the core layer and strontium-doped β-calcium silicate as the shell layer]

[0044] 1) Add 500 mL of 0.28 mol / L CaCl 2 , 0.08 mol / L MgCl 2 The pH value of the aqueous solution was adjusted to 10.6, and then the solution was added dropwise to 0.24 mol / L Na with a pH of 10.6 and a volume of 500 mL 2 HPO 4 2H 2 O in the aqueous inorganic salt solution, continue to stir for 45 minutes after the dropwise addition is completed, then filter the reaction deposit, wash with deionized water for 3 times, and then wash with absolute ethanol for 1 time, 80 o C drying, after 900 o C for 3 hours, and then ball milled for 4 hours to obtain a powder with a particle size of 2-6 μm. X-ray diffraction test proves that the phase of the powder is β-tricalcium phosphate. As tested by atomic absorption spectrometry, the magnesium content in the β-tricalcium phosphate powder is 8.34%.

[0045] 2) Add ...

Embodiment 3

[0047] Example 3: [Composite ceramic microspheres doped with strontium and magnesium β-tricalcium phosphate as the core layer and strontium and zinc doped α-calcium silicate as the shell layer]

[0048] 1) Add 500 mL of 0.30 mol / L CaCl 2 , 0.01 mol / L SrCl 2 , 0.05 mol / L MgCl 2 The pH value of the aqueous solution was adjusted to 10.6, and then the solution was added dropwise to 0.24 mol / L (NH 4 ) 2 HPO 4 In the aqueous solution of inorganic salt, continue to stir for 45 minutes after the dropwise addition is completed, then filter the reaction sediment, wash with deionized water for 3 times, and then wash with absolute ethanol for 1 time, 80 o C drying, after 850 o C for 3 hours, and then ball milled for 4 hours to obtain a powder with a particle size of 2-6 μm. X-ray diffraction test proves that the powder is β-tricalcium phosphate. The content of strontium and magnesium in the β-tricalcium phosphate powder is 1.46% and 5.84% respectively according to the analysis and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com