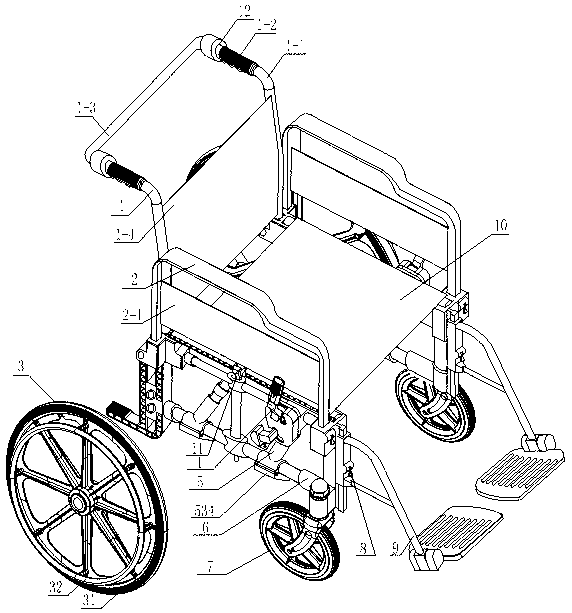

Full-plastic wheelchair

A technology for wheelchairs and frames, which can be used in patient chairs, special transportation tools, vehicle ambulance, medical transportation, etc. It can solve problems such as increased labor intensity and time, metal pipes are easy to rust, and corrosion effects, etc., to achieve convenience Production management, convenient operation, and the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

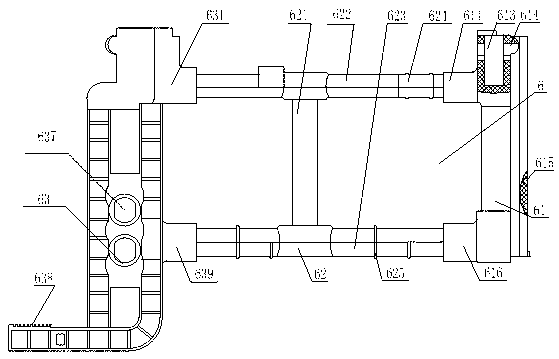

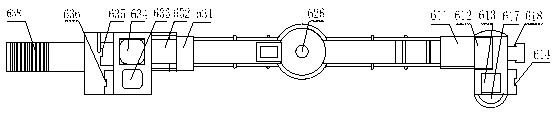

[0017] There is a vertical blind hole on the upper end face of the front bar 61, which is the jack 613 at one end of the handrail. The lower two bushings 611, 616 have a first locking hole 614 on the outer upper end to communicate with the jack 613 on the upper end surface, the first locking hole 614 is equipped with a lock catch 8, and there is more than one adjusting groove for the height of the pedal in the middle 615, a connecting column 617 with a through hole is arranged on one side of the lower end, and chute 618 is arranged on the two side walls of the outer surface.

[0018] There are two vertical but not connected blind holes on the upper end surface of the rear bar 63, which are the jack 633 and the back bar jack 634 at the other end of the handrail, and an arc-shaped rear groove 632. There are upper and lower two connecting pipes 631, 639 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com