Milk cooling device

A cooling device and milk technology, which is applied to the preservation of milk, dairy products, applications, etc., can solve the problems of slow cooling speed, inconvenience, large volume, etc., and achieve the effects of high cooling efficiency, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

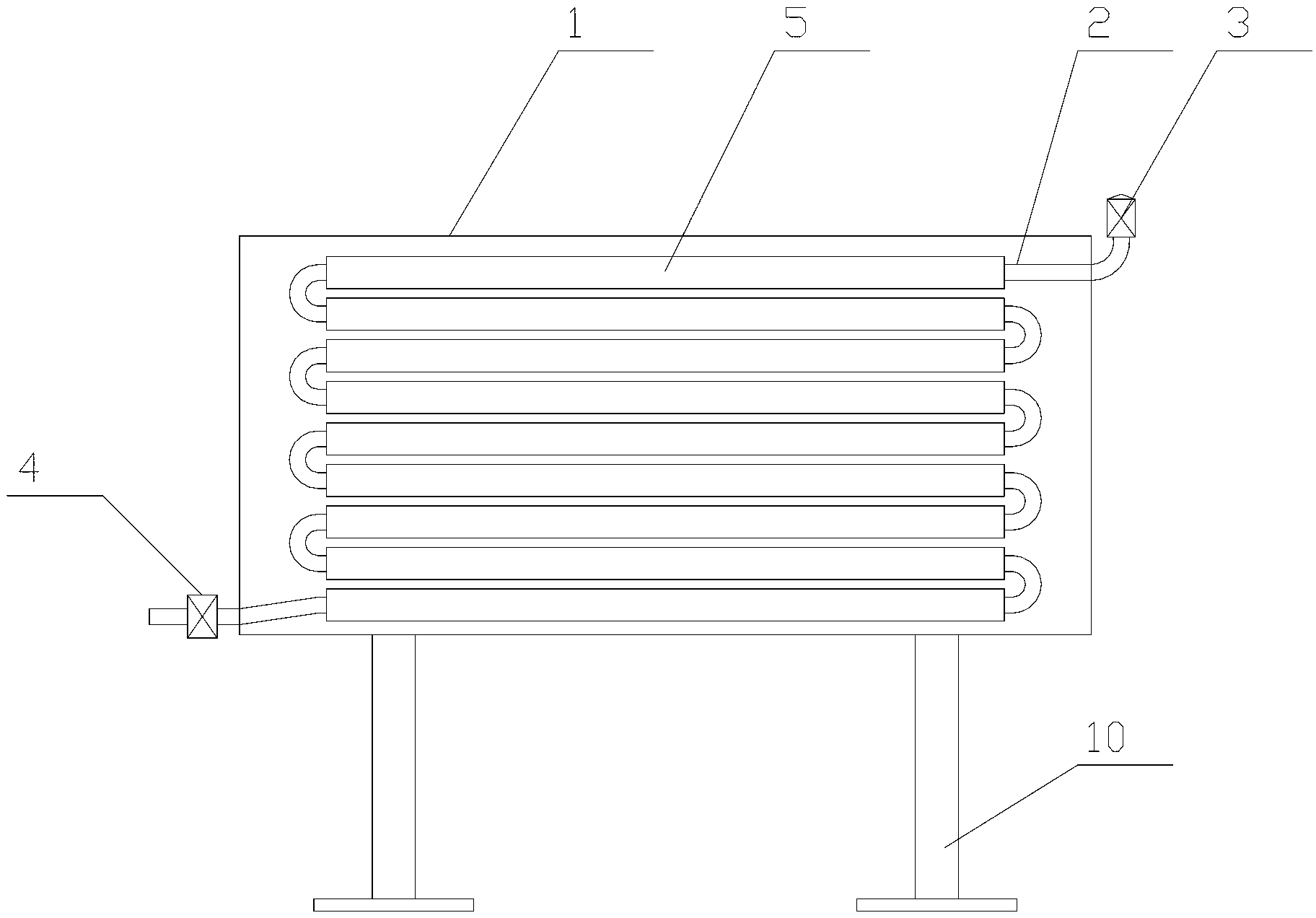

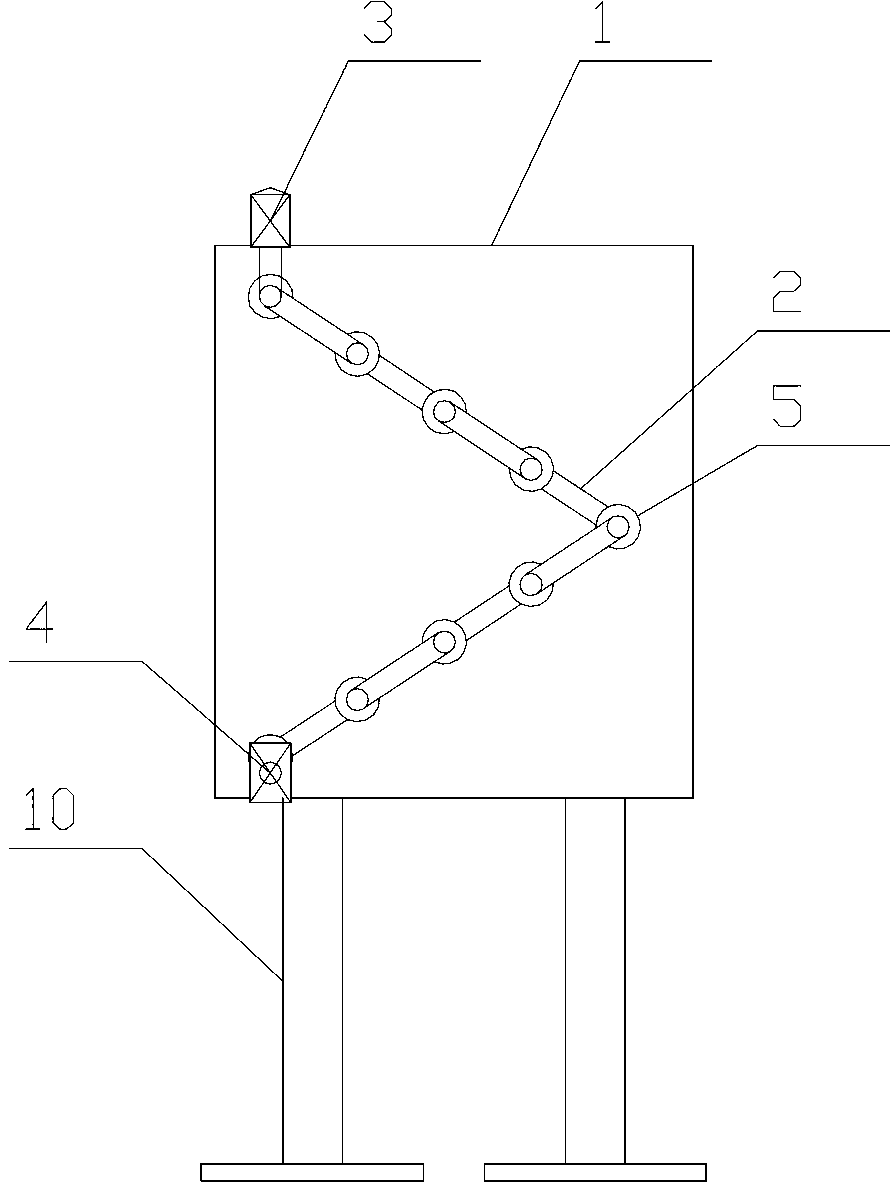

[0031] The present invention as Figure 1-8 As shown, it includes a housing 1 (the bottom surface of the housing 1 is provided with four legs 10 for improving its stability), a milk pipeline 2 and a cooling system 5, the top of the milk pipeline 2 is provided with a milk inlet 3, and The bottom end is provided with a milk outlet 4; this case is provided with an emptying valve at the milk inlet, so that when there is no milk at the end of milking, all the remaining milk in the milk pipeline can be drained.

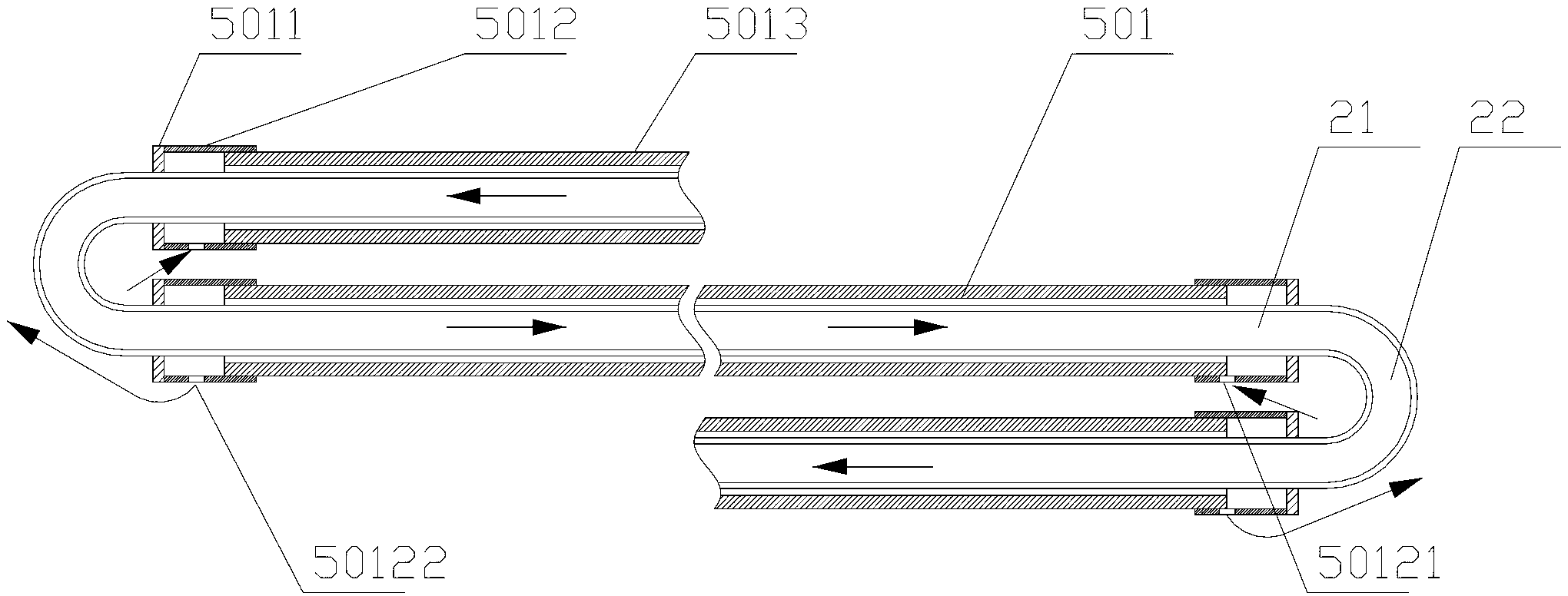

[0032] The milk pipeline 2 is arranged in the housing 1 in an S-shaped detour (so that the milk flow direction in adjacent milk pipelines is reversed), and the milk pipeline 2 includes several straight pipes 21 and is used to communicate with several straight pipes 21 The semicircular pipe 22; the straight pipe on the top layer communicates with the milk inlet at the top of the side wall of the housing, and the straight pipe at the bottom layer communicates with the milk ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com