Thermal error modeling method based on gray linear regression

A technology of linear regression and modeling methods, applied in simulators, instruments, computer control, etc., can solve problems such as no exponential growth, single thermal error model, and difficulty in describing linear change trends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

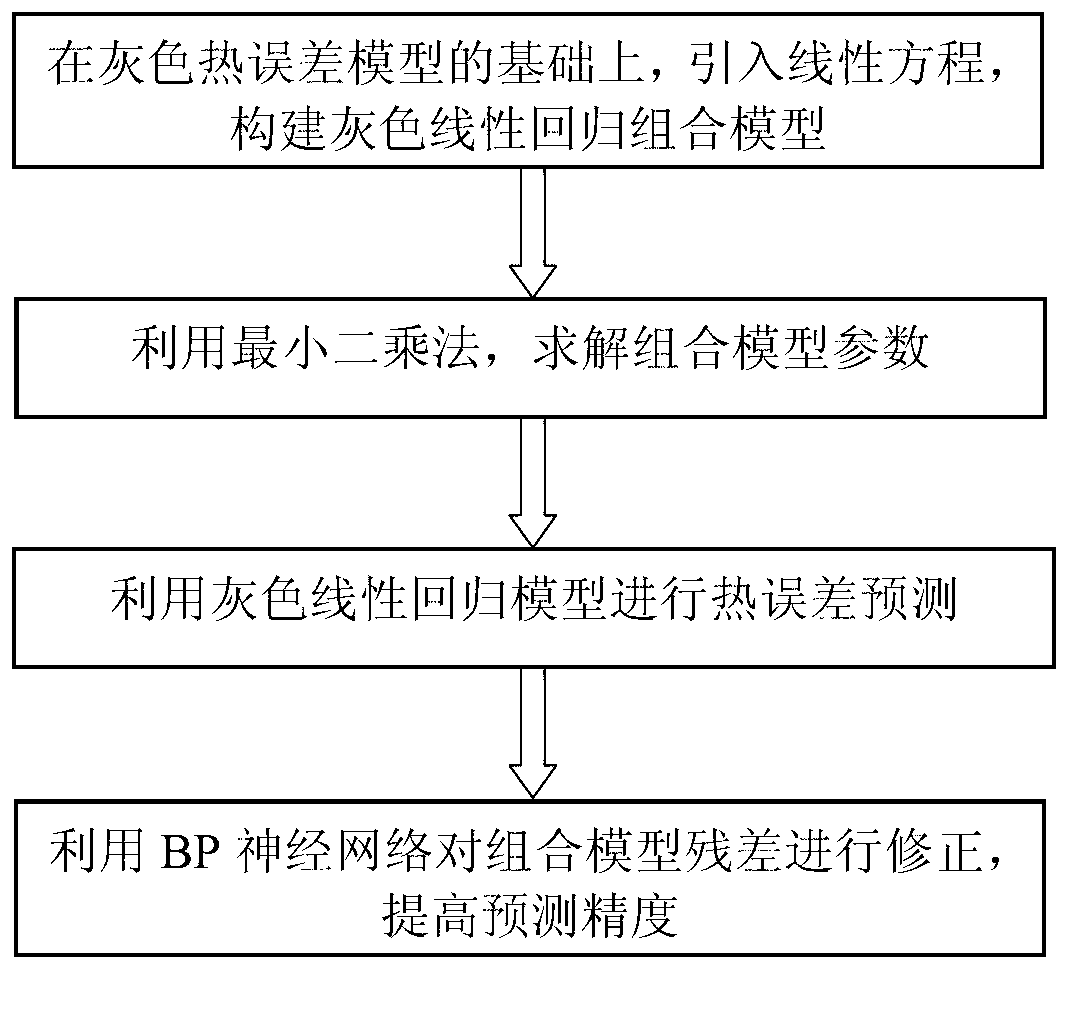

[0026] A flow chart of a thermal error modeling method based on gray linear regression in an embodiment of the present invention is as follows figure 1 As shown, the steps of the present invention will be further described below in conjunction with the flowchart. The specific implementation steps are as follows:

[0027] The first step: On the basis of the gray thermal error model, introduce a linear equation to construct a gray linear regression combination model;

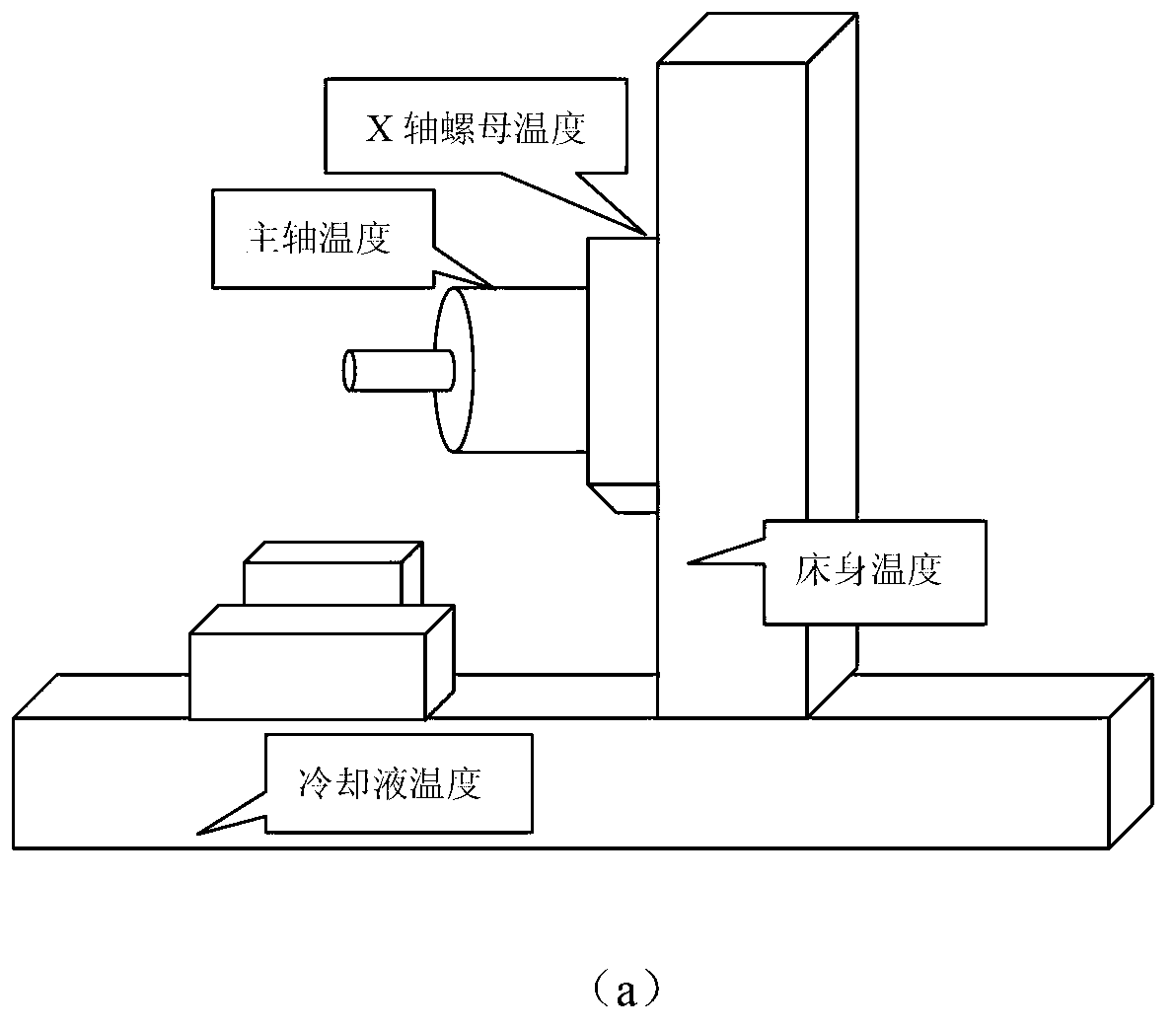

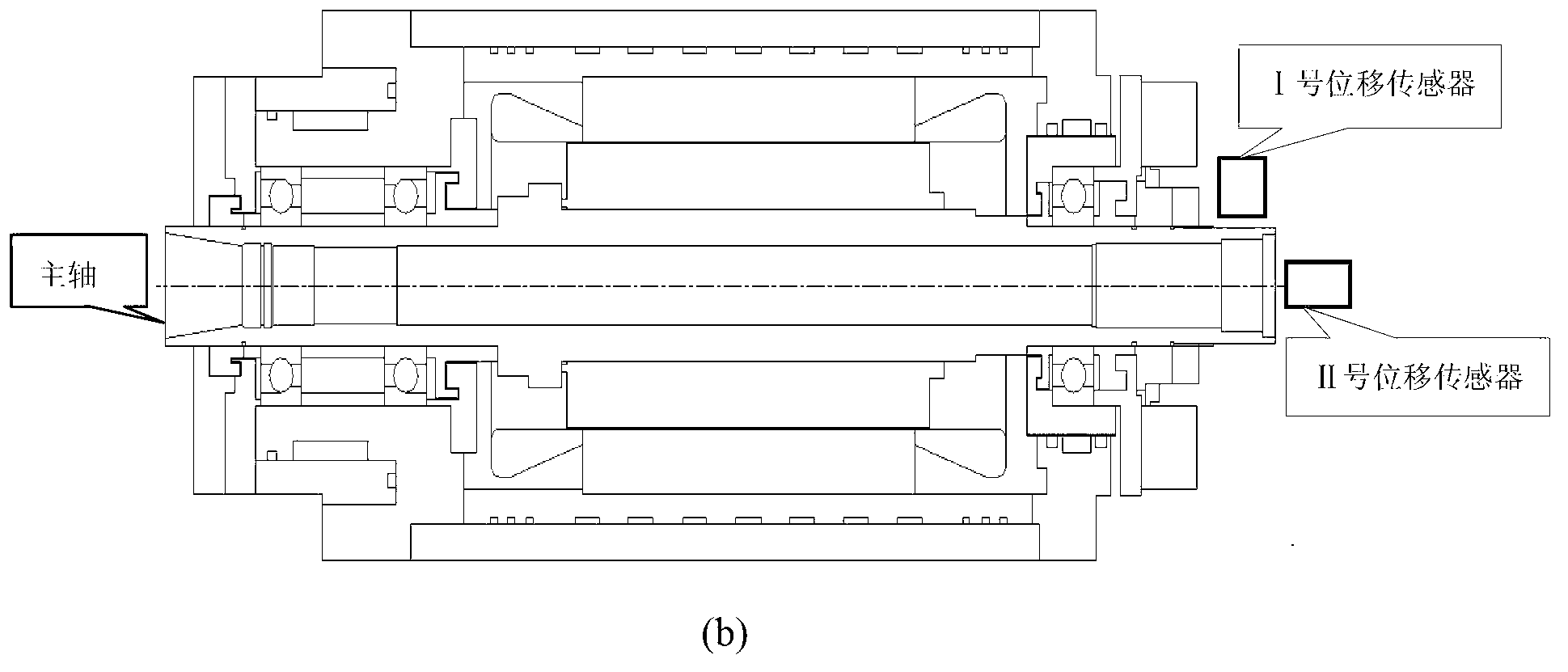

[0028] The thermal error trend of CNC machine tools can be analyzed by constructing a dynamic differential equation. Due to the uncertainty of the thermal error, the gray thermal error model is used to algebraically calculate the original data of the thermal error and process its gray variables to weaken the original data of the thermal error. The randomness in , so as to generate the thermal error prediction value with strong regularity.

[0029] Let X (0) =(x (0) (1),x (0) (2),...,x (0) (n)) is a thermal e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com