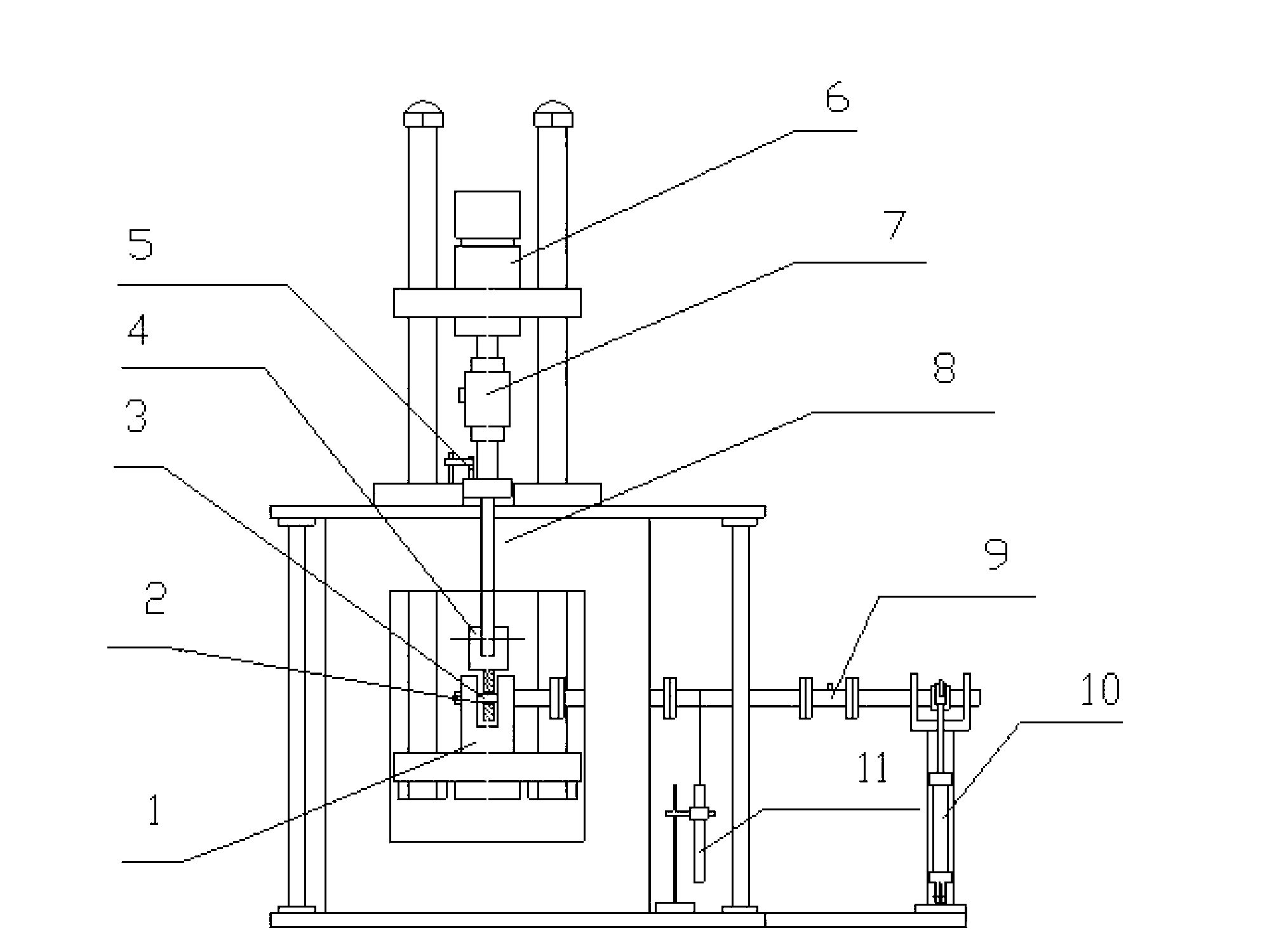

Apparatus used for bearing wearing test

A technology of bearing test and bearing wear, which is applied in the direction of testing wear resistance, etc., can solve the problems of high equipment maintenance cost, complicated test, unfavorable energy saving and consumption reduction, etc., and achieve the effect of solving the problem of difficult cooling and ensuring low temperature state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0011] See attached figure 1 As shown, the device for bearing wear test is characterized in that: the device includes a bifurcated base 1, the bearing test piece 2 is installed on the bifurcated base 1 through the mandrel 3, and the upper part of the bearing test piece 2 is connected to the loading unit. The ear 4 fits together, the loading single ear 4 is connected with the loading cylinder 6, and the loading cylinder 6 exerts radial vertical pressure downward on the bearing test piece 2, and the above-mentioned components are placed in the temperature test chamber 8;

[0012] The mandrel 3 is connected with the oscillating cylinder 10, and the oscillating cylinder 10 drives the mandrel 3 to perform a reciprocating rotation at an angle of ±25 degrees, and a wear displacement sensor 5 is arranged on the connecting rod between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com