Device and method for measurement of internal temperature of solid metal

A technology of internal temperature and measuring devices, applied in measuring devices, thermometers, measuring heat, etc., can solve the problems of not being able to measure the internal temperature of solid metals, and achieve the effects of easy installation and extraction, convenient installation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

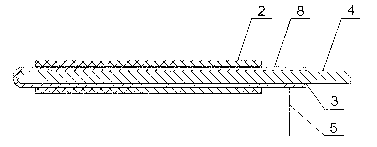

[0046] Such as figure 1 As shown, the solid metal internal temperature measuring device includes an insulating sleeve 2 and an armored thermocouple 3. The insulating sleeve 2 is sleeved on the armored thermocouple 3 and at least exposes the temperature measuring end of the armored thermocouple 3.

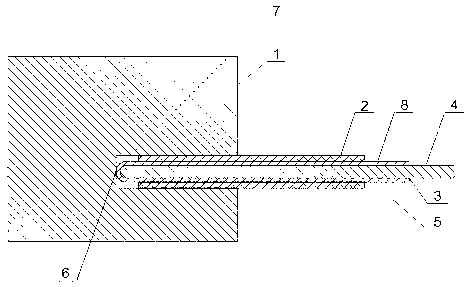

[0047] Such as figure 2 As shown, in this embodiment, when in use, it is directly inserted into the blind hole 7 on the metal 1 to be tested, so that the temperature measuring end of the armored thermocouple 3 is in contact with the bottom of the blind hole 7 .

[0048] If only armored thermocouples are used, the following problems will occur:

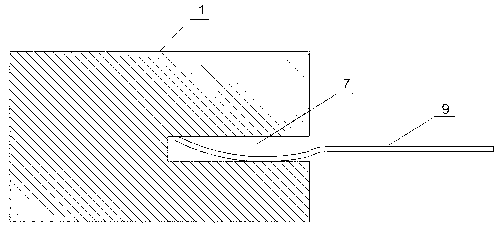

[0049] Such as image 3 As shown, when the flexible armored thermocouple 9 is selected, after it is inserted into the blind hole 7, it is difficult to ensure that the part inserted into the blind hole 7 does not bend. The hole wall of the blind hole 7 is in contact, and the temperature measuring end of the flexible armored thermocouple 9...

Embodiment 2

[0053] Such as figure 1 and figure 2 As shown, the present embodiment is based on Embodiment 1, and the armored thermocouple 3 includes a thermocouple wire 4 and an armored shell 8, and the armored shell 8 wraps the thermocouple wire 4, and the two ends of the armored shell 8 are both Exposed from the insulating sleeve 2 , it also includes a grounding wire 5 connected to the end of the armored shell 8 away from the temperature measuring end of the armored thermocouple 3 . When the metal 1 to be tested is charged, it will cause great electromagnetic interference to the armored thermocouple 3 that penetrates into the metal. By grounding the armored shell 8, effective shielding of electromagnetic interference can be achieved, so that this embodiment has a relatively Strong anti-interference ability. In addition, due to the existence of the insulating sleeve 2, the metal under test 1 can be prevented from being grounded after the armored shell 8 is grounded.

Embodiment 3

[0055] Such as figure 1 and figure 2 Shown, present embodiment is on the basis of above-mentioned embodiment, and the diameter of described armored thermocouple 3 is 5 * 10 -4 ~1.5×10 -3 m. Under the condition that the diameter of the blind hole 7 should be as small as possible, the selection of the armored thermocouple 3 with the above diameter can realize the internal temperature of the metal 1 to be tested without affecting the structure, internal temperature distribution and mechanical properties of the metal 1 to be tested. Measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com