High-efficiency burner for blast-type gas cooker

A gas cooker and burner technology, which is applied in the direction of gas fuel burners, burners, and combustion methods, and can solve problems such as excessive CO content in exhaust gas, burning of the main torch, and easy flame extinguishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

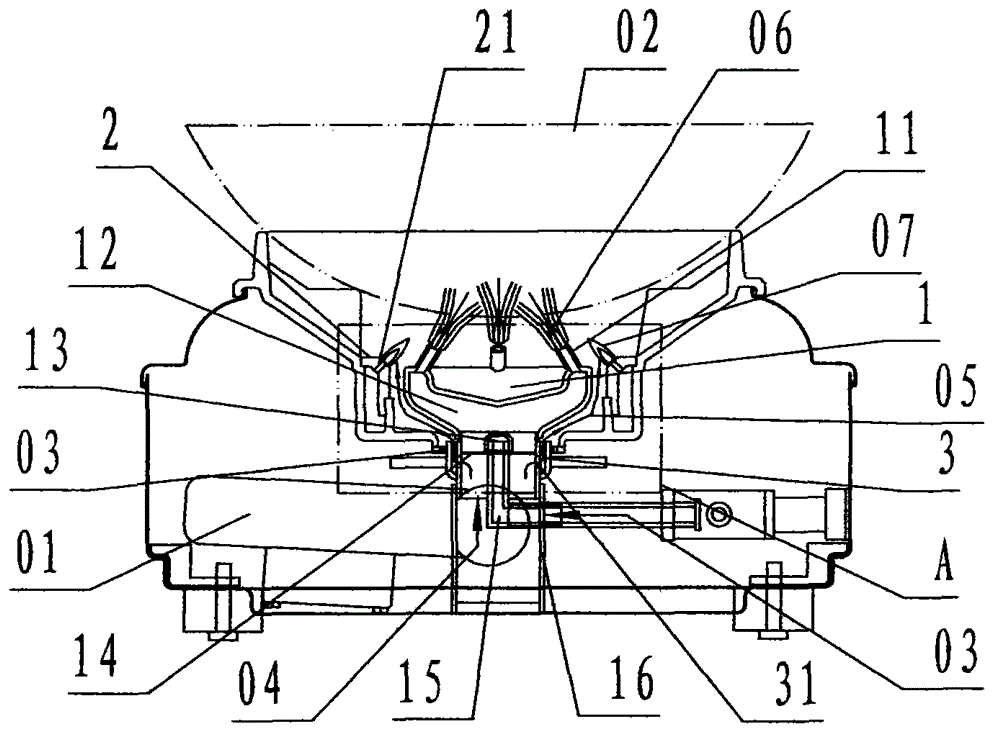

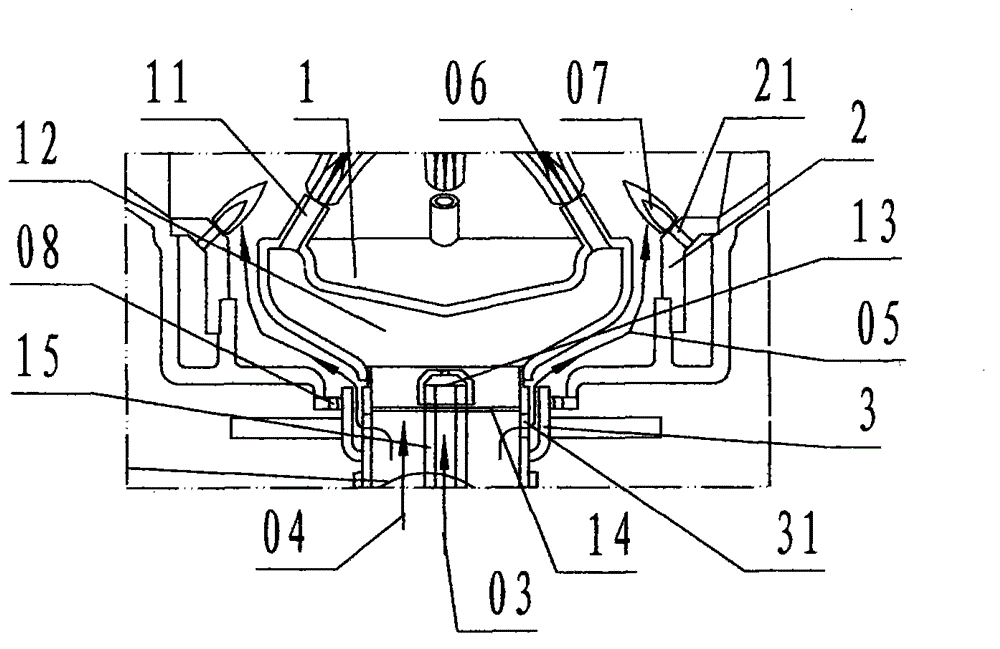

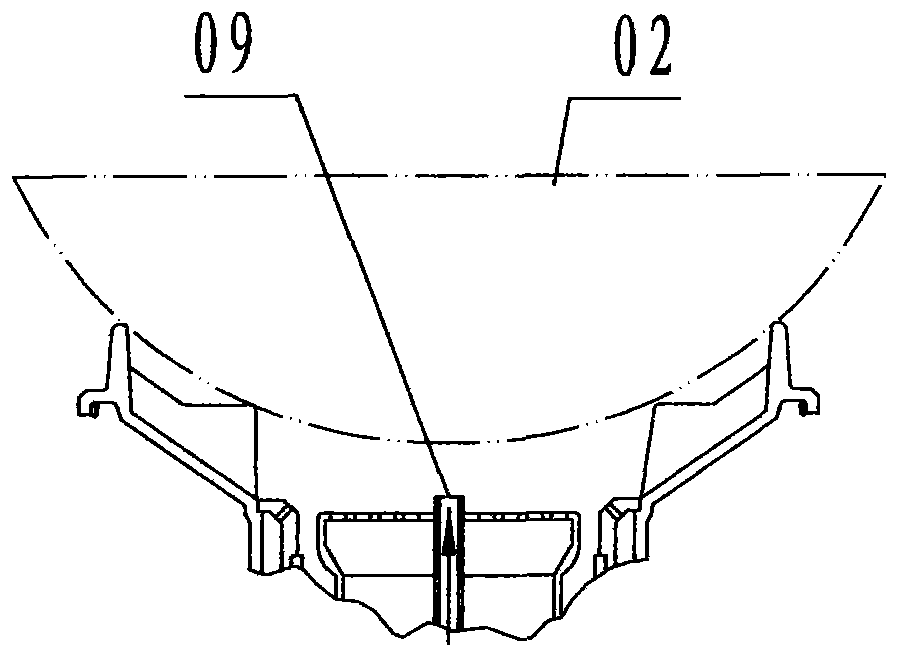

[0023] refer to figure 1 , figure 2 , a high-efficiency burner for a blast-type gas cooker according to the present invention, comprising a main torch 1, an ever-burning torch 2, and an air ring 3, wherein: the main torch 1 is large at the top and small at the bottom, and has a stepped cylindrical shape. The steel member with hollow wall, the inner chamber of the main torch 1 is called the mixing chamber 12; The nozzle with a cylindrical tubular shape is called a gas nozzle 13, and a rotating thin-plate type uniform damper 14 with an adjustable opening is provided between the bottom of the gas nozzle 13 and the inner wall of the mixing chamber 12, and the lower end of the gas nozzle 13 is connected to the gas The gas pipelines 15 of the cooker are connected and communicated; the upper edge of the main torch 1 is evenly distributed with a number of circular pipes that protrude upward and slant towards the center, and communicate with the inner chamber of the main torch 1, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com