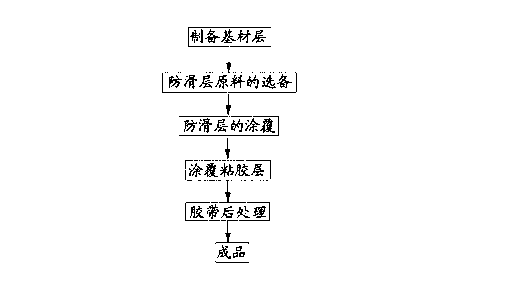

Method for preparing novel antiskid adhesive tape

A non-slip tape, a new type of technology, used in adhesives, film/flake adhesives, coatings, etc., can solve the problems of reducing the service life of the tape, low bonding strength, and unsatisfactory durability, and improve the service life. , The effect of reasonable process arrangement and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a) Prepare the substrate layer, the substrate layer is a blended fabric cloth, its main components are: carbon fiber and polyester fiber, the blending ratio of the two fibers is 25%:75%; the preparation process includes: drawing, roving, spun yarn, winding In the drawing process, the share ratio of the two yarns is about 1:3, the diameter of the blended yarn after winding is about 0.15mm, and the density of the woven fabric is 220* 248; After the fabric cloth is prepared, it needs to be hot-pressed and dried, and the thickness of the substrate layer is about 0.25mm;

[0018] b) Selection of raw materials for the anti-slip layer. The main components of the anti-slip layer and their percentage ratios are: sand material 45%, filler 55%; the sand material is corundum sand, and the particle size of the sand material is about 150-200 mesh; The main components and percentage ratio of the filler are: polyurethane resin 75%, solvent 25%, and the solvent can be acetone solution w...

Embodiment 2

[0024] a) Prepare the substrate layer, the substrate layer is a blended fabric, its main components are: carbon fiber and polyester fiber, the blending ratio of the two fibers is 30%:70%; the preparation process includes: drawing, roving, spun yarn, winding Cone, woven forming, etc., the share ratio of the two yarns in the drawing process is about 1:3, the wire diameter of the blended yarn after winding is about 0.16mm, and the density of the woven fabric is 220* 248; After the fabric cloth is prepared, it needs to be hot-pressed and dried, and the thickness of the substrate layer is about 0.28mm;

[0025] b) Selection of raw materials for the anti-slip layer. The main components of the anti-slip layer and their percentage ratios are: 50% sand material and 50% filler; the sand material is made of quartz sand, and the particle size of the sand material is about 150-200 mesh; The main components and percentage ratio of the filler are: 80% polyurethane resin, 20% solvent, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com