System and method for fine treatment of condensation water

A condensate fine treatment and condensate technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc., can solve problems such as unit outage and prone to failure, Achieve the effects of saving floor space, increasing potential safety hazards, and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

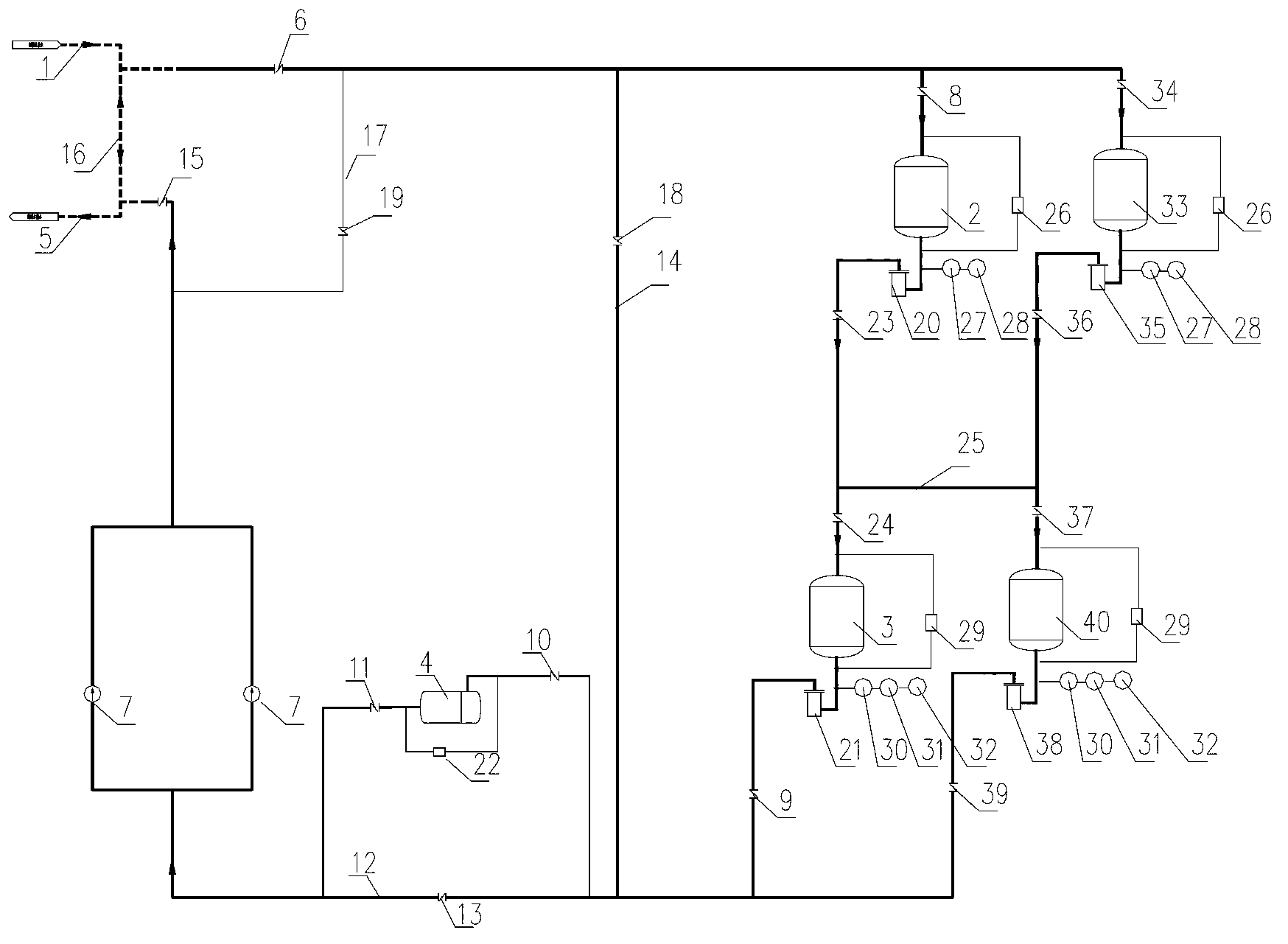

[0030] Embodiment 1 of the present invention: a condensate polishing system, including a pipeline inlet 1, a pipeline outlet 5, a cation exchanger 2, an anion-cation mixed ion exchanger 3 and a filter 4, a pipeline inlet 1, a cation exchanger 2. Anion and cation mixed ion exchanger 3, filter 4 and pipeline outlet 5 are connected in series through the connecting pipeline in sequence, a booster pump 7 is arranged on the connecting pipeline between filter 4 and pipeline outlet 5, and pipeline inlet 1 The connection pipeline between the cation exchanger 2 and the valve 16 and the valve 3 A8 are provided, and the connection pipeline between the cation exchanger 2 and the anion and cation mixed ion exchanger 3 is provided with a valve ten A23 and a valve eleven A24, and the cation A resin catcher 20 is arranged between the exchanger 2 and the valve ten A23, and a valve four A9 and a valve six 10 are arranged on the connecting pipeline between the anion and cation mixed ion exchanger ...

Embodiment 2

[0046] Embodiment 2 of the present invention: a condensate polishing system, including a pipeline inlet 1, a pipeline outlet 5, a cation exchanger 2, an anion-cation mixed ion exchanger 3 and a filter 4, a pipeline inlet 1, a cation exchanger 2. Anion and cation mixed ion exchanger 3, filter 4 and pipeline outlet 5 are connected in series through the connecting pipeline in sequence, a booster pump 7 is arranged on the connecting pipeline between filter 4 and pipeline outlet 5, and pipeline inlet 1 The connection pipeline between the cation exchanger 2 and the valve 16 and the valve 3 A8 are provided, and the connection pipeline between the cation exchanger 2 and the anion and cation mixed ion exchanger 3 is provided with a valve ten A23 and a valve eleven A24, and the cation A resin catcher 20 is arranged between the exchanger 2 and the valve ten A23, and a valve four A9 and a valve six 10 are arranged on the connecting pipeline between the anion and cation mixed ion exchanger ...

Embodiment 3

[0062] Embodiment 3 of the present invention: a condensate polishing system, comprising a pipeline inlet 1, a pipeline outlet 5, a cation exchanger 2, an anion-cation mixed ion exchanger 3 and a filter 4, a pipeline inlet 1, a cation exchanger 2. Anion and cation mixed ion exchanger 3, filter 4 and pipeline outlet 5 are connected in series through the connecting pipeline in sequence, a booster pump 7 is arranged on the connecting pipeline between filter 4 and pipeline outlet 5, and pipeline inlet 1 The connection pipeline between the cation exchanger 2 and the valve 16 and the valve 3 A8 are provided, and the connection pipeline between the cation exchanger 2 and the anion and cation mixed ion exchanger 3 is provided with a valve ten A23 and a valve eleven A24, and the cation A resin catcher 20 is arranged between the exchanger 2 and the valve ten A23, and a valve four A9 and a valve six 10 are arranged on the connecting pipeline between the anion and cation mixed ion exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com