Road finisher and method for determining layer thickness of resulting paving layer

A finishing machine, layer thickness technology, applied in the direction of road repair, roads, roads, etc., can solve the problems of increased manufacturing costs, differences, complex road finishing machines, etc., to reduce production costs, simplify metering settings, and reduce overall calculation work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

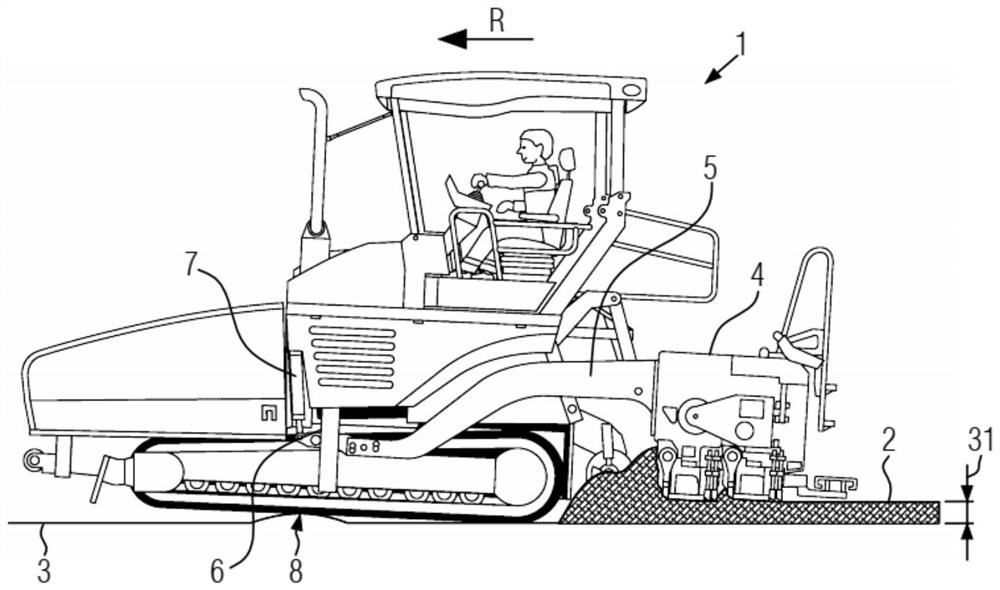

[0048] figure 1 A road finishing machine 1 is shown, which produces a pavement layer 2 on a roadbed 3 , on which the road finishing machine 1 is moved in a paving direction R during a paving operation. The road finishing machine 1 is equipped with a height-adjustable paving screed 4 for (pre)compacting the paving layer 2 . The paving screed 4 is attached to a screed bar 5 which is connected at a front towing point 6 to a leveling cylinder 7 of the road finisher 1 . The screed strips 5 are used as levers to translate changes in the position of the leveling cylinders into changes in the angle of attack of the paving screed 4 , in particular to compensate for irregularities 8 in the roadbed 3 .

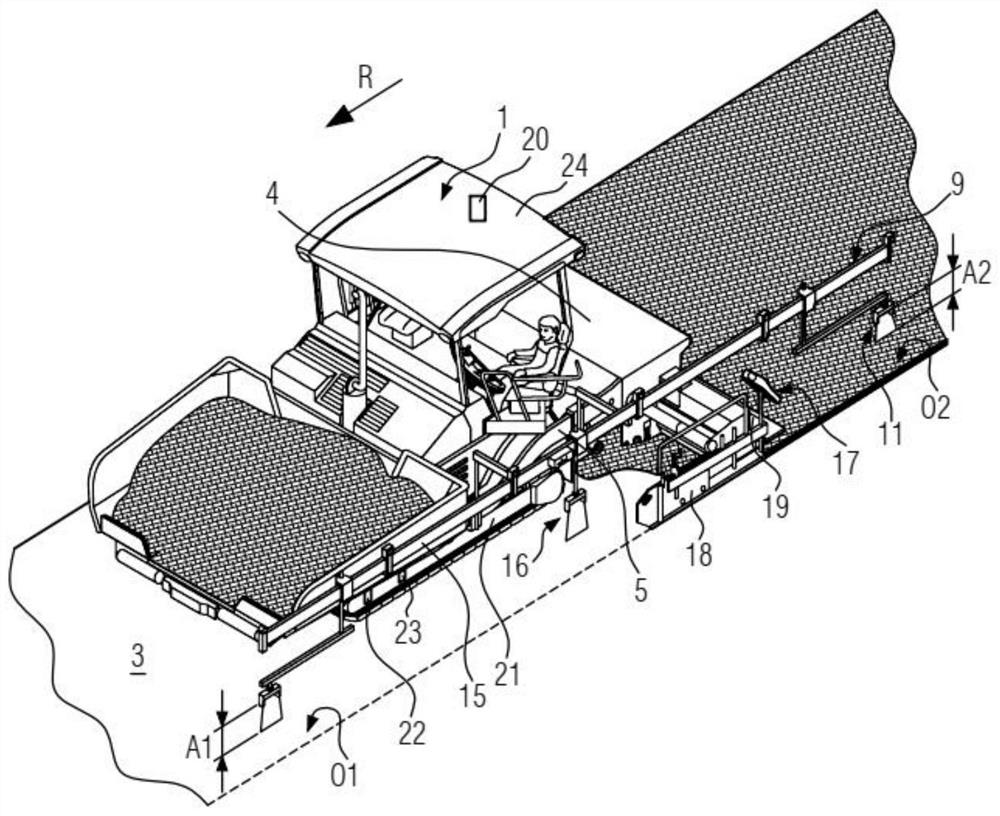

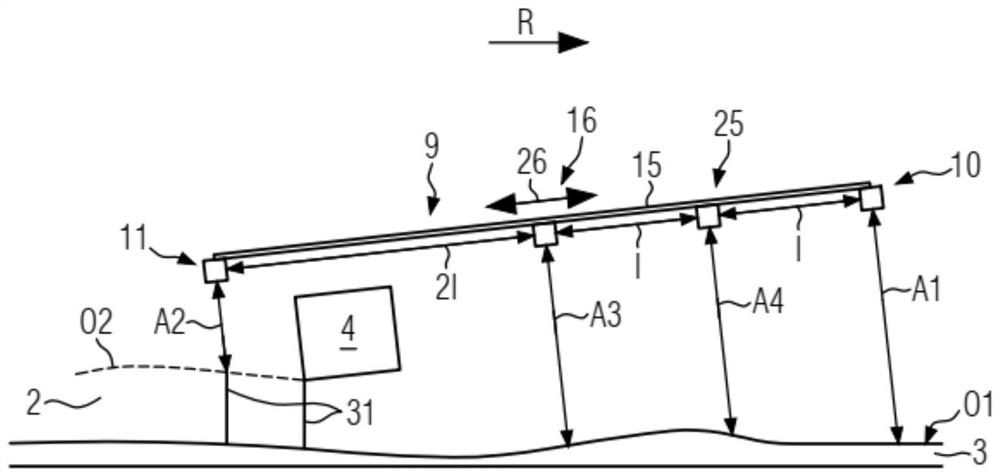

[0049] figure 2 The road finishing machine 1 is shown in a paving operation. exist figure 2 Among them, the paving screed 4 is configured as a telescopic screed. The first measuring device 9 is located on the screed bar 5 . The measuring device 9 comprises a first sensor unit 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com