Catalyst for synthesizing methanol through carbon dioxide hydrogenation as well as preparation method and application thereof

A technology for synthesizing methanol and carbon dioxide, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydroxyl compound preparation, etc., can solve the problem of methanol selectivity and low yield, and low carbon dioxide conversion rate and other problems, to achieve the effect of easy industrial amplification, large number of strong alkaline sites, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

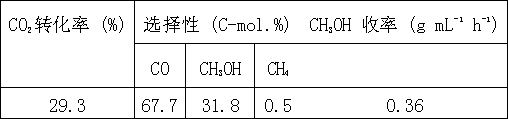

[0017] Embodiment 1. Prepare the mixed solution according to the molar ratio of metal atoms as follows: Cu2Zn1Al0.9La0.1 (each element is dissolved in the middle of deionized water in the form of nitrate to form a mixed solution), in addition, sodium hydroxide and sodium carbonate molar ratio It is 10:1 to make a mixed precipitant solution. At 60 °C, the two mixed solutions were co-precipitated. The precipitation process needs to be fully stirred to maintain pH = 13, aged for 36 h under stirring conditions at 40 °C, and the precipitate was washed with deionized water until no sodium ions were detected. At 160 °C dried at 700 °C for 2 h to obtain CuO / ZnO / Al 2 o 3 / La 2 o 3Metal oxide catalyst, the metal atom molar ratio of this catalyst is: n(Cu):n(Zn):n(Al):n(La) = 2:1:0.9:0.1, it is crushed to 40-60 mesh . The reaction of hydrogenation of carbon dioxide to methanol was carried out in a fixed-bed reactor. After reduction with pure hydrogen at 250 °C for 15 h, it was coole...

Embodiment 2

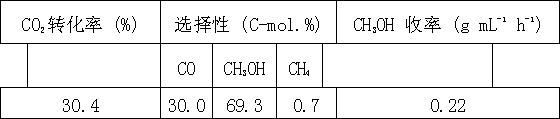

[0019] Embodiment 2. The mixed solution is prepared according to the molar ratio of metal atoms as follows: Cu1Zn1Al0.9Ga0.1 (each element is dissolved in the middle of deionized water in the form of nitrate to form a mixed solution), in addition, sodium hydroxide and sodium carbonate molar ratio It is 2:1 to make a mixed precipitant solution. At 10 °C, the two mixed solutions were co-precipitated. The precipitation process required sufficient stirring to maintain pH = 13. Aging was carried out at 100 °C for 1 h, and the precipitate was washed with deionized water until no sodium ions were detected. dried at 400 °C for 8 h to obtain CuO / ZnO / Al 2 o 3 / Ga 2 o 3 Metal oxide catalyst, the molar ratio of metal atoms of the catalyst is: n(Cu):n(Zn):n(Al):n(Ga) = 1:1:0.9:0.1, which is crushed to 40-60 mesh . The reaction of hydrogenation of carbon dioxide to methanol was carried out in a fixed-bed reactor. The pure hydrogen was reduced at 350 °C for 4 h and then cooled to room t...

Embodiment 3

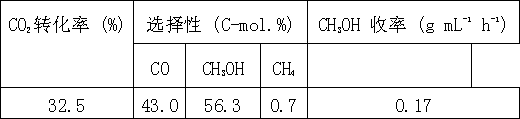

[0021] Example 3. A mixed solution was prepared according to the molar ratio of metal atoms as follows: Cu2Zn1Al0.8Y0.1Zr0.1 (except that Zr is in the form of zirconyl nitrate, and all other elements are dissolved in deionized water in the form of nitrate to form a mixed solution), In addition, the molar ratio of sodium hydroxide and sodium carbonate is 5:1 to form a mixed precipitant solution. At 25 °C, the two mixed solutions were co-precipitated. The precipitation process required sufficient stirring to maintain pH = 10. Aging was carried out at 60 °C for 15 h under stirring conditions. The precipitate was washed with deionized water until no sodium ions were detected. dried at 500 °C for 4 h to obtain CuO / ZnO / Al 2 o 3 / Y 2 o 3 / ZrO 2 Metal oxide catalyst, the metal atom molar ratio of this catalyst is: n(Cu):n(Zn):n(Al):n(Y):n(Zr)=2:1:0.8:0.1:0.1, will It is crushed to 40-60 mesh. The reaction of hydrogenation of carbon dioxide to methanol was carried out in a fixed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com