Preparation and application of chromotropic acid intercalated hydrotalcite composite material

A composite material and hydrotalcite technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve high selectivity and high effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Take Chromotropic acid and use 200ml to remove CO 2 deionized water to prepare a concentration of 0.3mol / L Chromotropicacid solution, adjust the pH value to 7 with 2M NaOH solution; then add 0.06molZn(NO 3 ) 2 ·6H 2 O, 0.02molAl(NO 3 ) 3 9H 2 O;

[0020] 2) Take 9.60g NaOH and use 200ml to remove CO 2 deionized water to prepare alkaline solution;

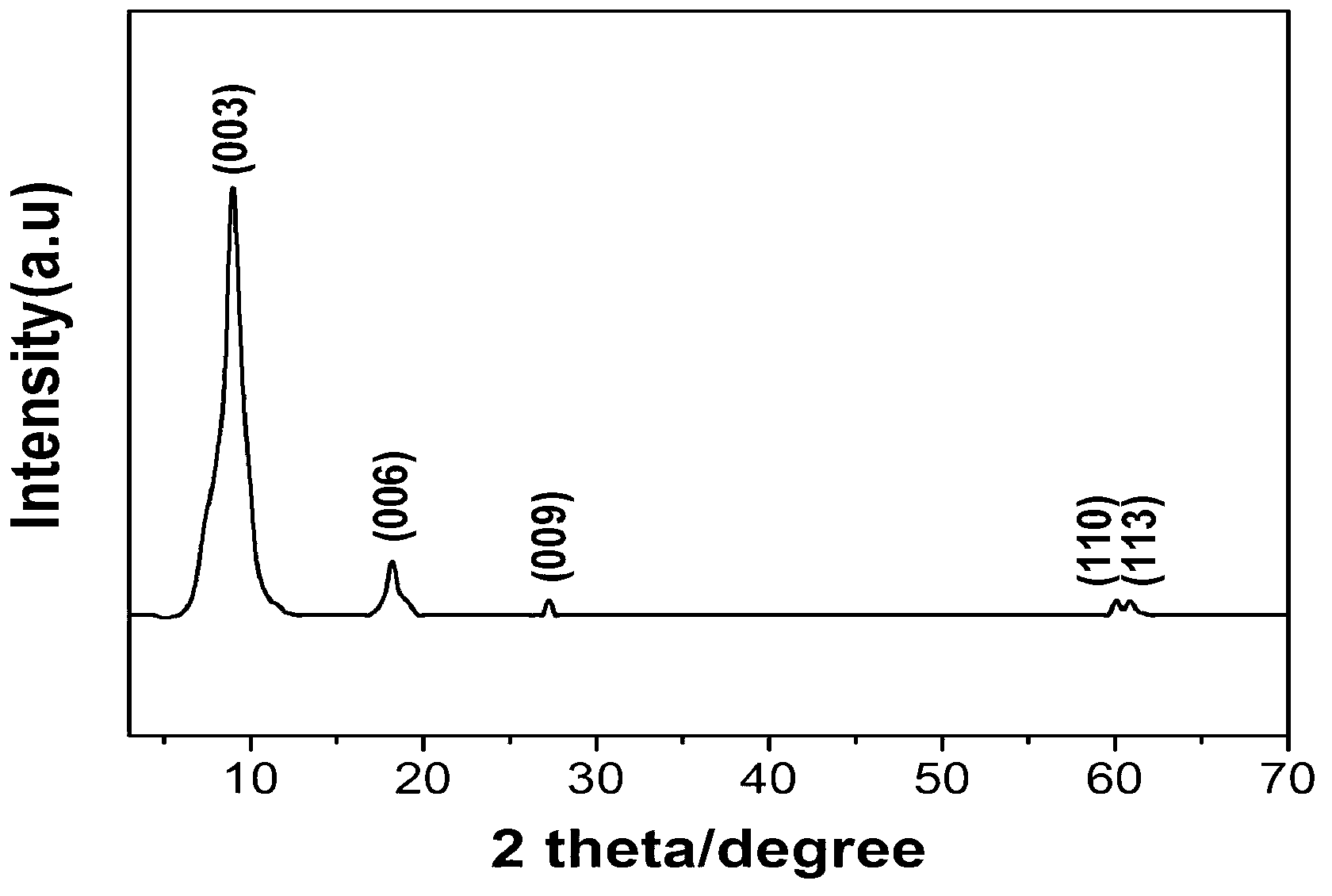

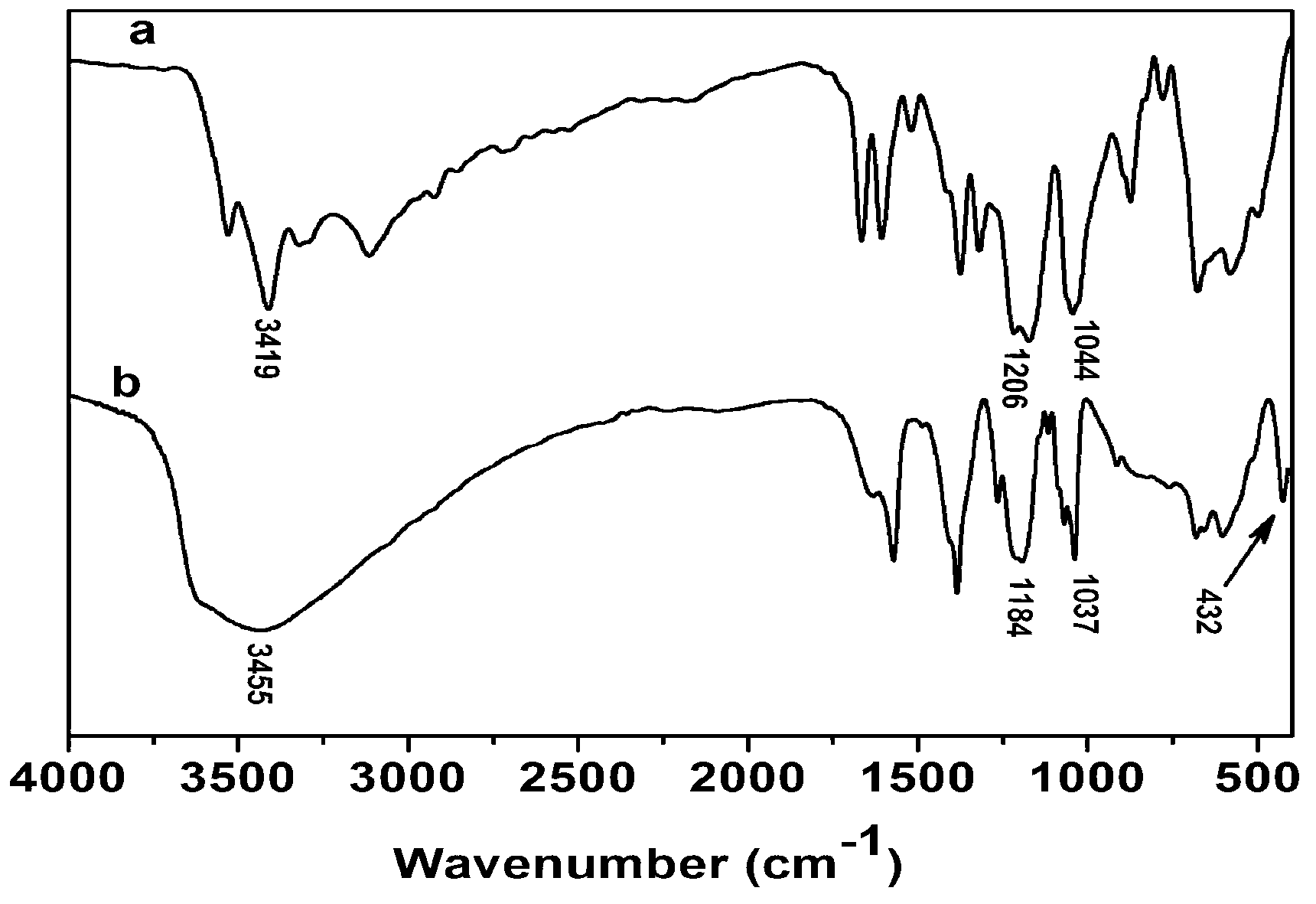

[0021] 3) Add the solution prepared in step 1) and step 2) into the colloid mill with a rotation speed of 3000rpm and mix for 2 minutes, and the obtained suspension is placed in an inert atmosphere N 2 Reflux aging at 97°C for 8 hours under protection, the product was centrifuged and washed 4 times, and dried in vacuum to obtain the Chromotropicacid intercalated hydrotalcite composite material Zn 3 Al-CTA-LDH, its chemical formula is [Zn 2+ 1-x al 3+ x (OH) 2 ] x+ (C 10 h 6 o 8 S2 2- ) x / 2 ﹒ 3H 2 O, x=0.25.

Embodiment 2

[0023] 1) Take Chromotropic acid and use 200ml to remove CO 2 deionized water to prepare a concentration of 0.8mol / L Chromotropicacid solution, adjust the pH value to 7 with 2M NaOH solution; then add 0.06molMg(NO 3 ) 2 ·6H 2 O, 0.02molAl(NO 3 ) 3 9H 2 O;

[0024] 2) Take 9.6g NaOH and use 200ml to remove CO 2 deionized water to prepare alkaline solution;

[0025] 3) Add the solution prepared in step 1) and step 2) into the colloid mill with a rotation speed of 3000rpm to mix for 4 minutes, and the obtained suspension is placed in an inert atmosphere N 2 Reflux aging at 97°C for 10 h under protection, the product was centrifuged and washed 3 times, and dried in vacuum to obtain the Chromotropicacid intercalated hydrotalcite composite material Mg 3 Al-CTA-LDH, its chemical formula is [Mg 2+ 1-x Al 3+ x (OH) 2 ] x+ (C 10 h 6 o 8 S 2 2- ) x / 2 ﹒ 5H 2 O, x=0.25.

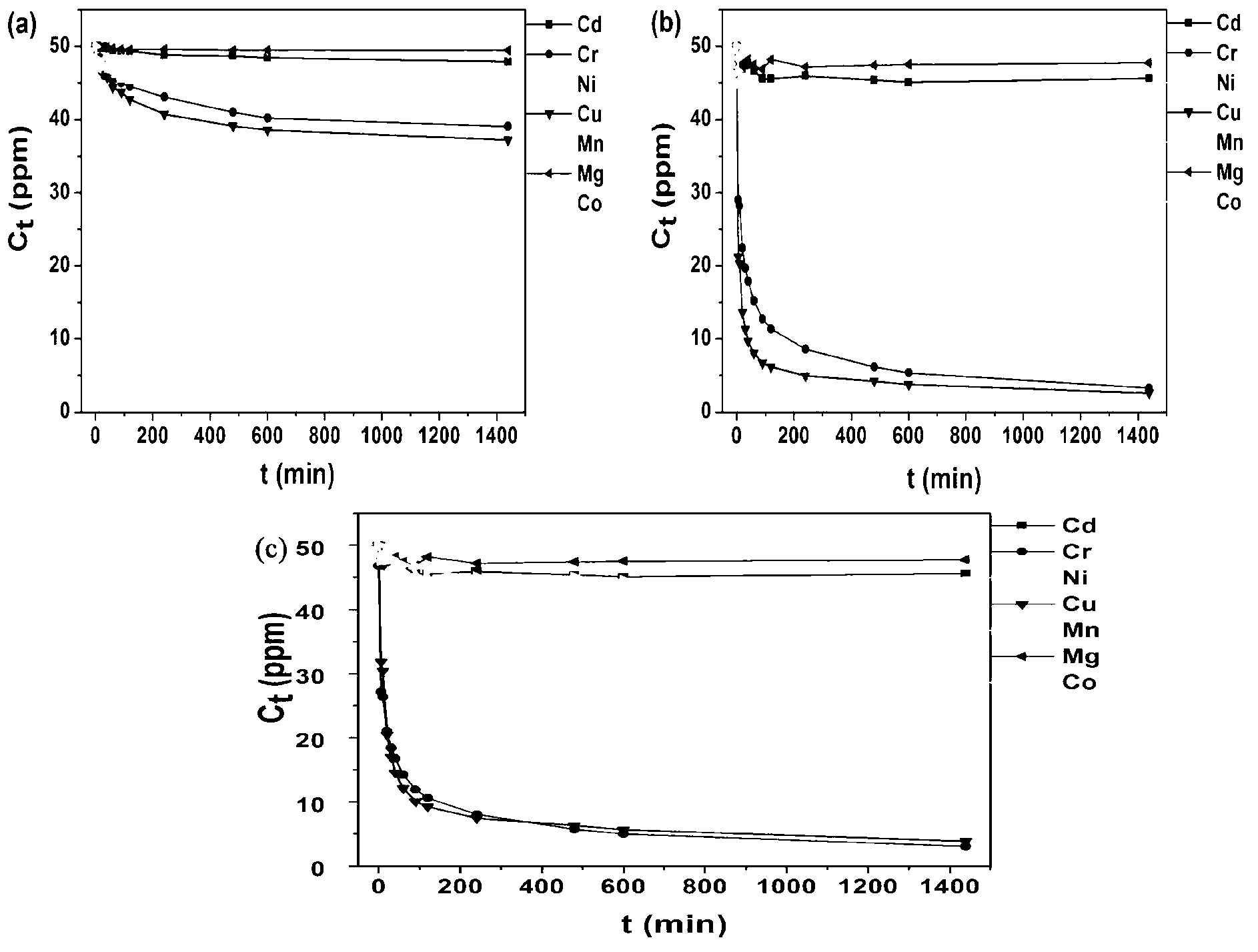

[0026] In order to verify the adsorption performance of the Chromotropicacid intercalated hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com