Dipping liquid for microwaveable frozen pre-fried flour-warped products and processing method of dipping liquid

A technology of microwave freezing and processing method, applied in the field of food processing, can solve the problem of losing the crispy taste of fried food and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

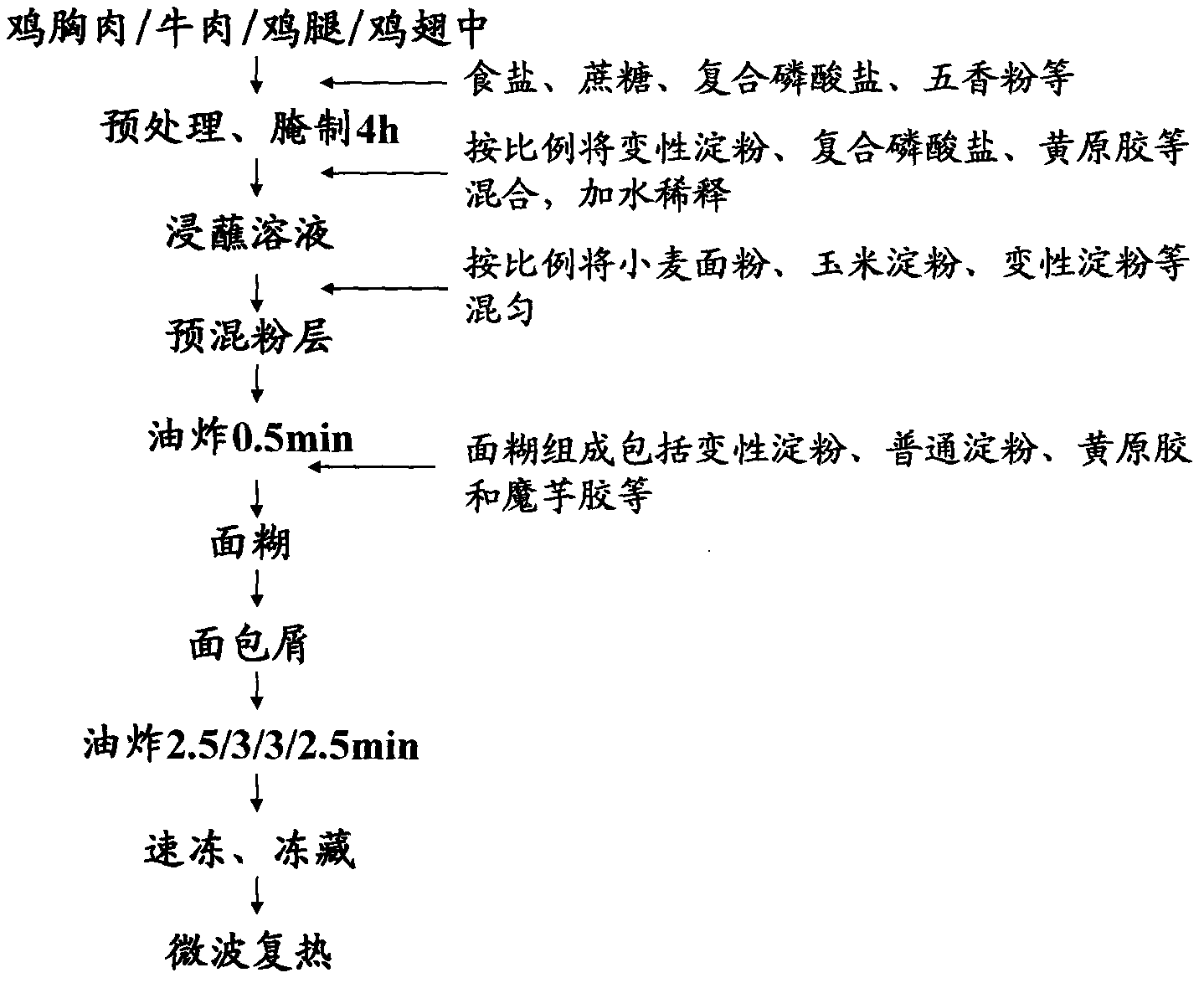

Method used

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: The dipping solution for microwave-freezing pre-fried breaded products of this embodiment is composed of the following components in terms of weight ratio: xanthan gum 8, carrageenan 2, tapioca modified starch 30, soybean 15 protein isolates, 5 monoglycoside esters, 5 complex phosphates, and 35 powder coatings.

specific Embodiment approach 2

[0016] Specific embodiment two: The dipping solution for the microwave-freezing pre-fried breaded products of this embodiment is composed of the following components in terms of weight ratio: xanthan gum 5, carrageenan 5, tapioca modified starch 25, soybean Protein isolate 20, powder coating 45.

specific Embodiment approach 3

[0017] Specific embodiment three: The 4 dipping liquids that can be microwave-freezed and pre-fried in the present embodiment are used in breaded products, and are composed of the following components in terms of weight ratio: xanthan gum 6, carrageenan 4, tapioca modified starch 20, Soy protein isolate 10, coating powder 50, monoglycoside 2, compound phosphate 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com