Liquid crystal aligning agent suitable for photo-lignment process, and liquid crystal alignment film using same

A technology of liquid crystal alignment agent and liquid crystal alignment film, which is applied in optics, nonlinear optics, coating, etc., and can solve problems such as insufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

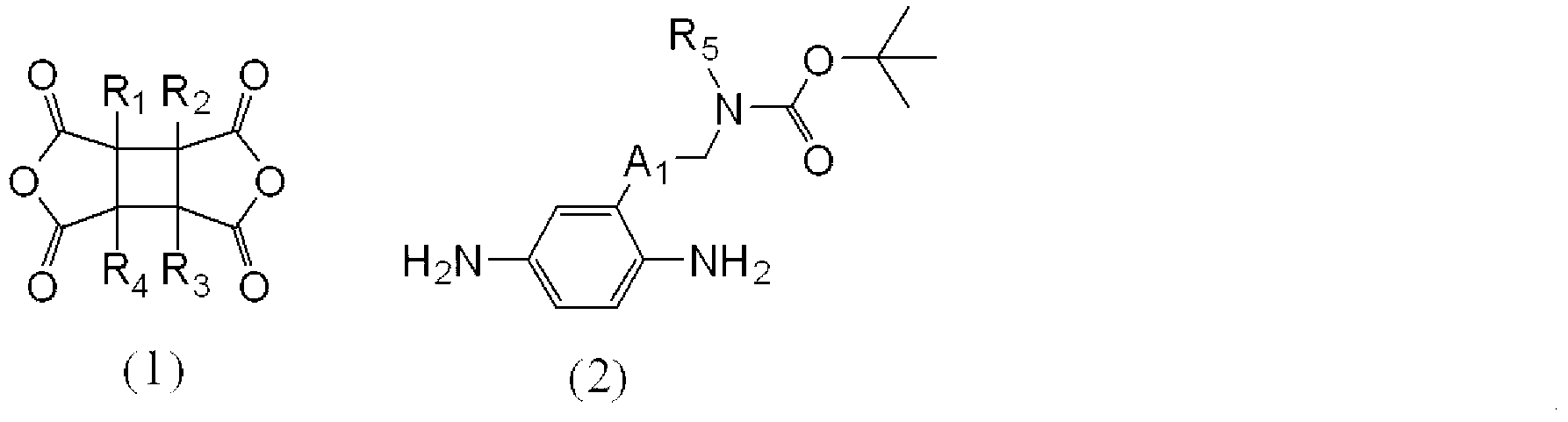

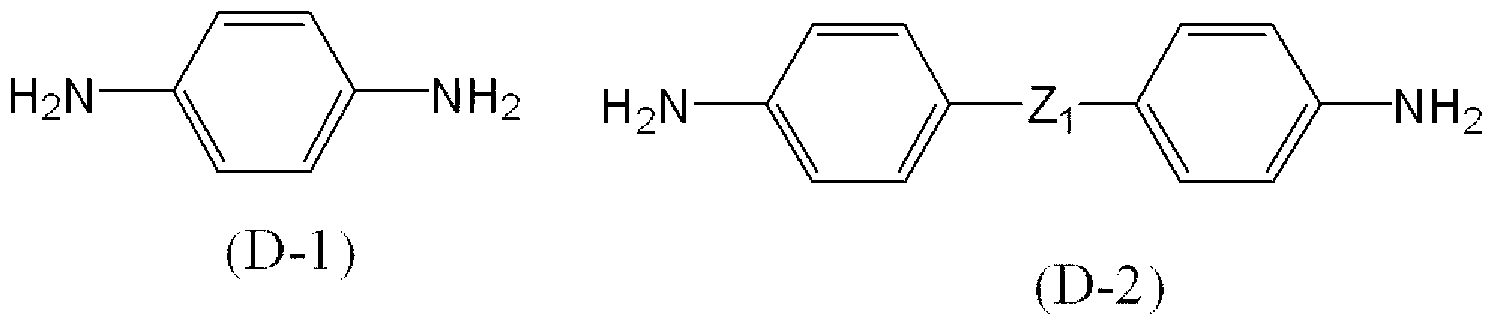

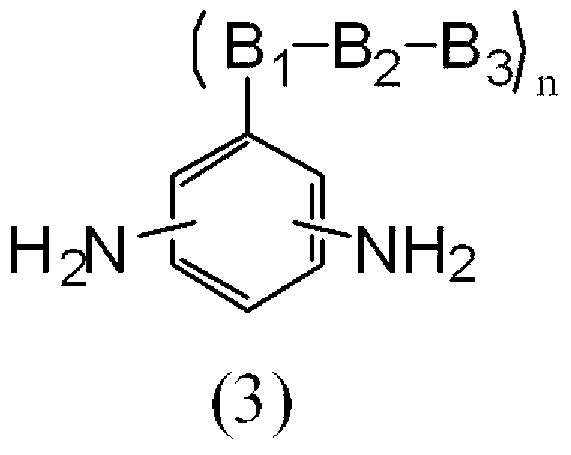

Synthetic example 1

[0212] Take 2.92g (27.0mmol) of p-phenylenediamine and 0.67g (3.0mmol) of DA-1 in a 100mL four-necked flask with a stirring device and a nitrogen inlet tube, add 52.27g of NMP, and stir while feeding nitrogen Let it dissolve. While stirring the diamine solution, 6.66 g (29.7 mmol) of 1,3-dimethyl-1,2,3,4-cyclobutanetetracarboxylic dianhydride was added, and NMP was added to make the solid content concentration 15 % by weight, stirred at room temperature for 24 hours to obtain a solution of polyamic acid (PAA-1). The viscosity of the polyamic acid solution at a temperature of 25° C. was 680 mPa·s. In addition, the molecular weight of this polyamic acid is Mn=9279, Mw=21886.

Synthetic example 2

[0214] Take 2.60g (24.0mmol) of p-phenylenediamine and 1.34g (6.0mmol) of DA-1 in a 100mL four-neck flask with a stirring device and a nitrogen inlet tube, add 52.65g of NMP, and stir while feeding nitrogen Let it dissolve. While stirring the diamine solution, 6.59 g (29.4 mmol) of 1,3-dimethyl-1,2,3,4-cyclobutanetetracarboxylic dianhydride was added, and NMP was added to make the solid content concentration 15 % by weight, stirred at room temperature for 24 hours to obtain a solution of polyamic acid (PAA-2). The viscosity of the polyamic acid solution at a temperature of 25° C. was 357 mPa·s. In addition, the molecular weight of this polyamic acid is Mn=9042, Mw=19958.

Synthetic example 3

[0216] Take 1.94g (17.9mmol) of p-phenylenediamine and 0.44g (1.97mmol) of DA-1 in a 100mL four-port burning screen with a stirring device and a nitrogen introduction tube, add 49.86g of NMP, and feed in nitrogen while Stir to dissolve. While stirring this diamine solution, add 3.77g (19.2mmol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride, and then add NMP to make the solid content concentration 10% by weight, and stir at room temperature for 24 hours , to obtain a solution of polyamic acid (PAA-3). The viscosity of the polyamic acid solution at a temperature of 25° C. was 142 mPa·s. In addition, the molecular weight of this polyamic acid is Mn=11494, Mw=24376.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com