Plastic bottleneck excess material detecting method and device based on machine vision

A technology of machine vision and detection method, which is applied in the direction of optical detection of defects/defects, etc., can solve the problems of separation of bottle mouth internal information and bottle body background information, damage to filling equipment, and limit detection speed, etc., to achieve low machine performance requirements and reduce The space occupied by the equipment and the effect of avoiding misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

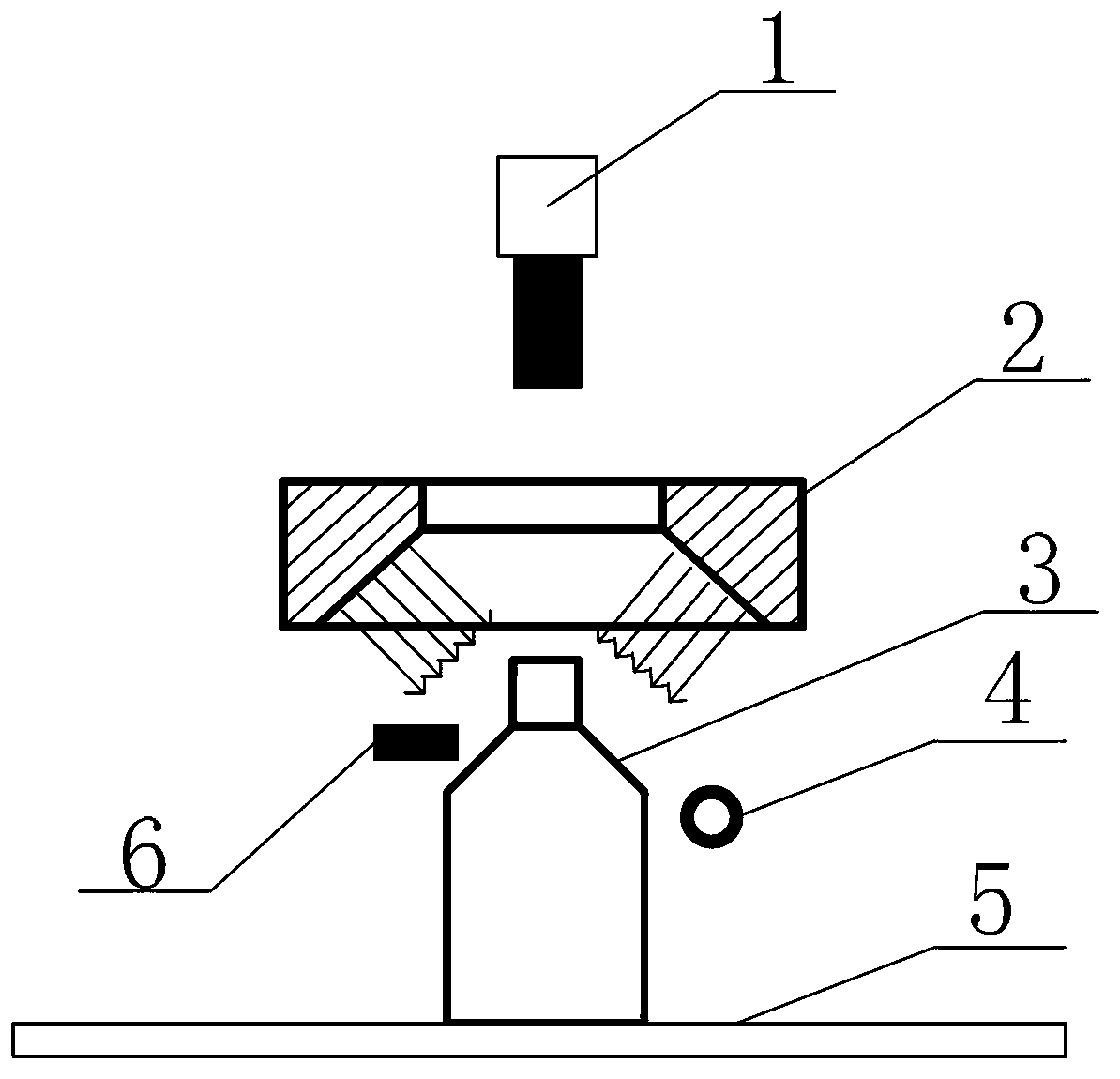

[0028] Such as figure 1 , figure 2 , image 3 shown. The machine vision-based detection device for remaining material at the mouth of a plastic bottle of the present invention includes a computer system (not shown in the figure), one for taking pictures of the bottle mouth image and putting it into an imaging unit, one for processing the bottle mouth image and A processing unit for defect identification, and a rejecting unit for rejecting plastic bottles 3 with residual material in the mouth of the bottle.

[0029] The imaging unit includes a position sensor 6, a light source 2, a camera 1, and a light source controller (not shown in the figure). The camera 1, the light source 2 and the mouth of the plastic bottle are on the same vertical line. The position sensor 6 transmits the signal to the light source controller and the camera 1 to trigger the light source 2 to light up and the camera 1 to take pictures. The light source uses ring light. Adjust the distance between c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com