Linear LED light source

A technology of LED light source and LED chip, applied in the field of LED light source, can solve the problems of product breakage, high price, poor toughness, etc., and achieve the effects of cost reduction, material reduction, and strong heat dissipation capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

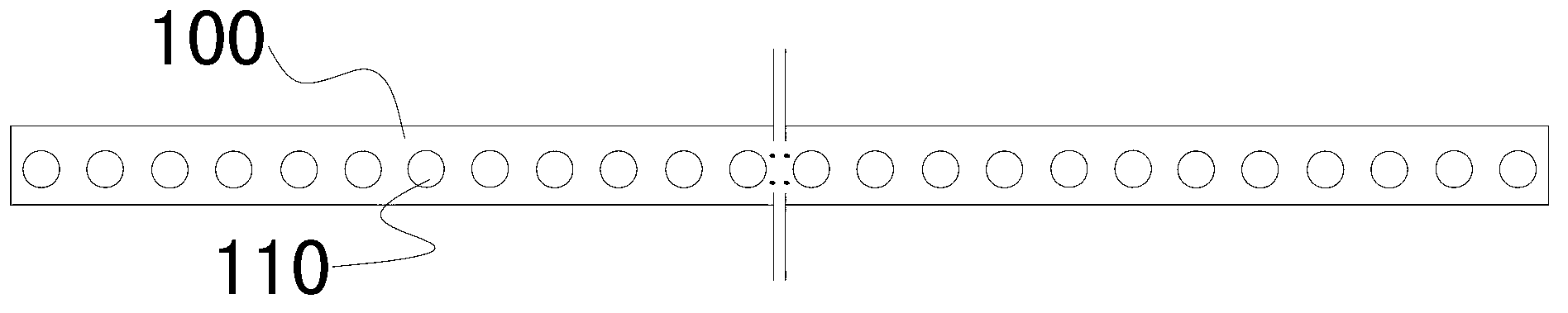

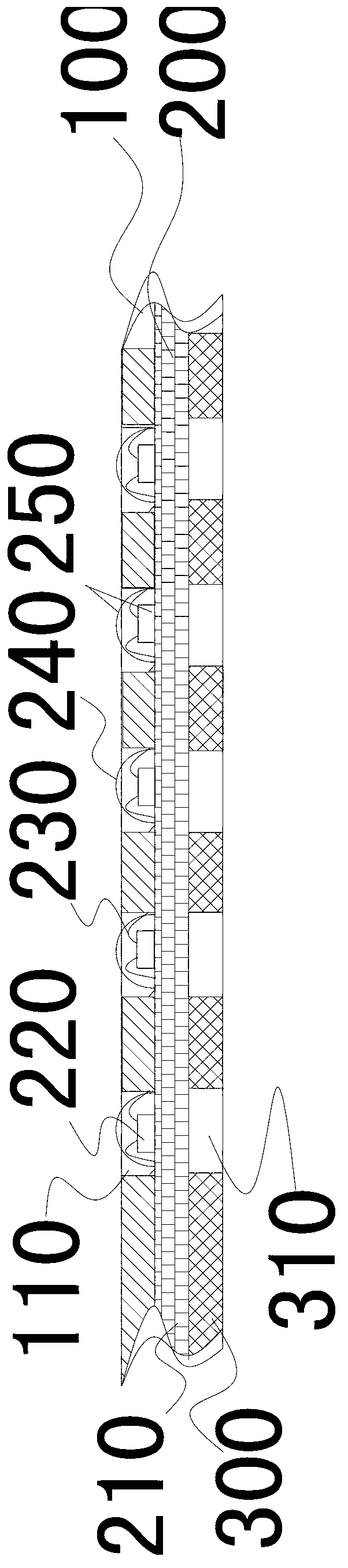

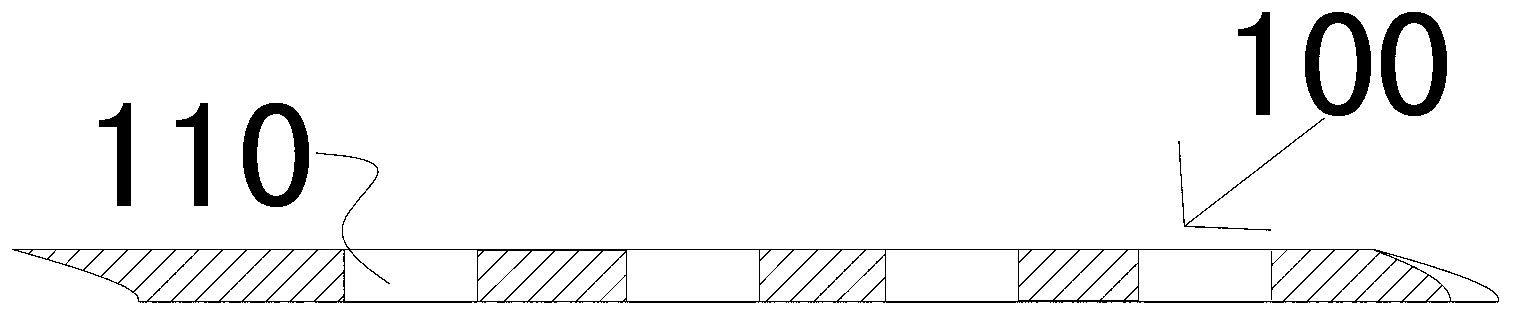

[0025] figure 1 It is a schematic plan view of the present invention, figure 2 It is an enlarged view of the side structure of the present invention. like figure 1 and figure 2 As shown, a linear LED light source has a three-layer structure, which are: reflective paper 100, aluminum foil layer 200 and thermally conductive double-sided adhesive tape 300, which are stacked sequentially from top to bottom, and the surface of the uppermost layer is reflective paper 100.

[0026] like figure 1 As shown, the reflective paper 100 is provided with a plurality of light-transmitting holes 110, the LED chip 220 and the protective film 240 formed by transparent glue form a protruding light source part 250, and is arranged in the light-transmitting hole 110, and the surface of the LED chip 220 is also sprinkled. There are phosphors, and the protective film 240 formed by phosphors and transparent glue increases the light transmittance of the LED light source. At the same time, differe...

Embodiment 2

[0035] Image 6 It is a schematic plan view of the aluminum foil layer in Example 2. like Image 6 As shown, the LED chips 220 of the present invention can be connected not only in series but also in series. After the series connection is adopted, it is not possible to use the aluminum foil strip 210 as a whole. Therefore, the aluminum foil layer 200 will be composed of individual pieces of aluminum foil 260 instead of the rectangular strip structure in the first embodiment. A plurality of LED chips 220 are adhered to corresponding numbers of aluminum foils 260 with a transparent adhesive, and the distance between the aluminum foils 260 is about 0.3 mm, and then the LED chips 220 are connected through connecting wires 230 to form a series connection. All the other parts are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com