Molecular spring vibration isolation buffering technology

A molecular spring and vibration isolation technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber, etc., can solve the problems of easy aging of components, insufficient bearing capacity, complicated additional equipment, etc., and achieve easy maintenance and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

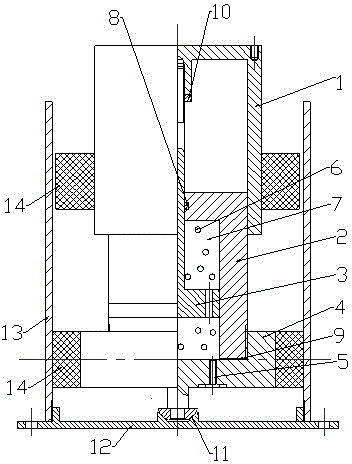

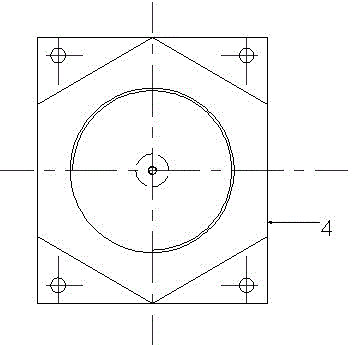

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] The invention utilizes the feature that water molecules can enter the nanopores of the hydrophobic zeolite particles when the pressure increases, and automatically escape from the nanopores when the pressure decreases, and proposes a brand new vibration isolation technology. Water and hydrophobic zeolite particles are sealed in a hydraulic container to obtain a mixed medium molecular spring, and the energy conversion and loss characteristics of the nanoscale hydrophobic capillary in the zeolite flowing through the water molecule under high pressure are used to achieve vibration isolation and buffer protection for the equipment; the molecular spring can be used for Vibration isolation, vibration reduction and buffering; due to the difficulty of water molecules entering and exiting nanopores at different pressure stages, molecular springs exhibit the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com