Piston type engine crank connecting rod mechanism

A technology of crank connecting rod mechanism and piston engine, which is applied in the directions of engine components, machines/engines, pistons, etc., can solve the problem of affecting the structural movement stability of the crank connecting rod mechanism, increasing the contact area between the top surface of the piston and the combustion chamber, and affecting the combustion. Indoor gas mixing and combustion problems, to achieve the effect of reducing maintenance costs, reducing contact area, and helping in-cylinder combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

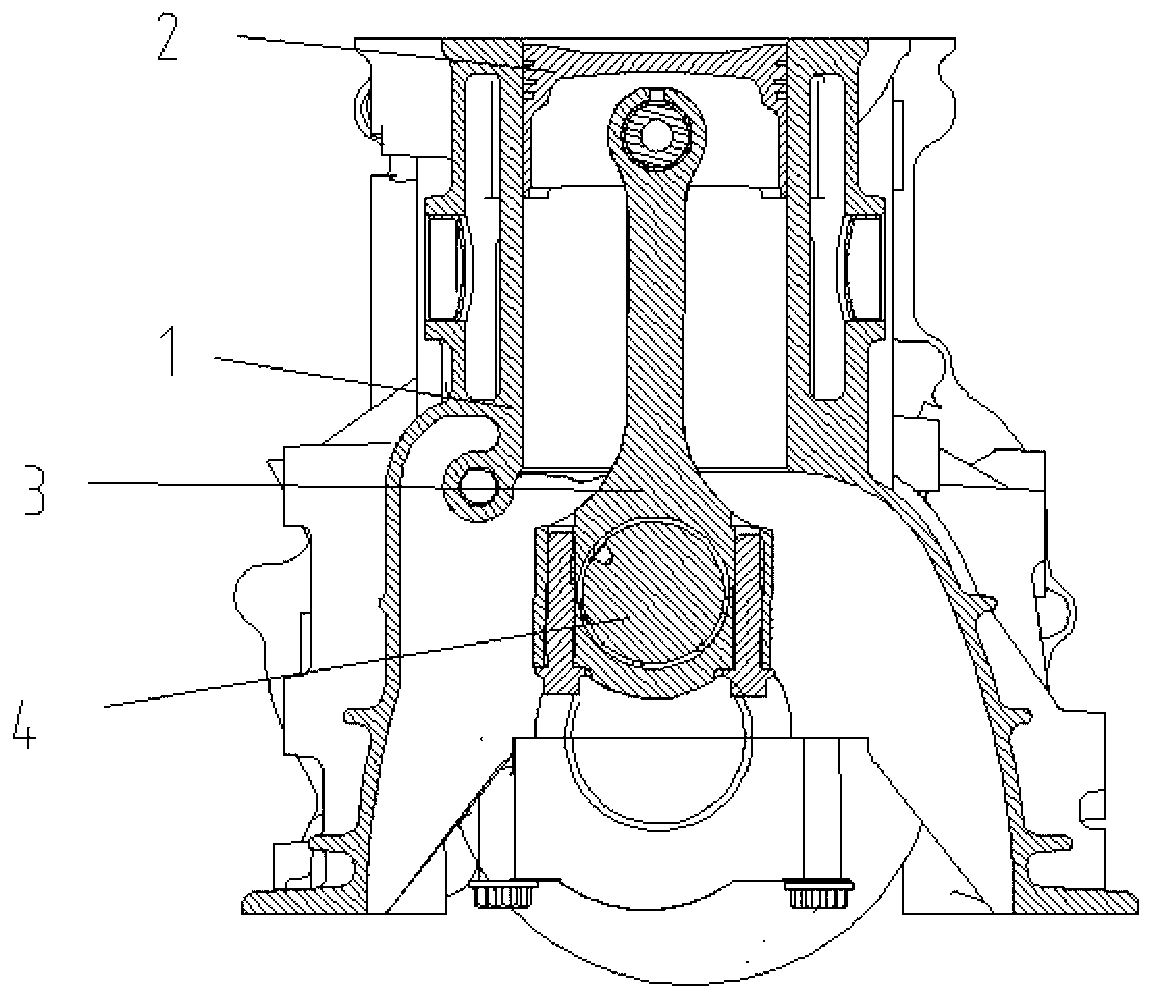

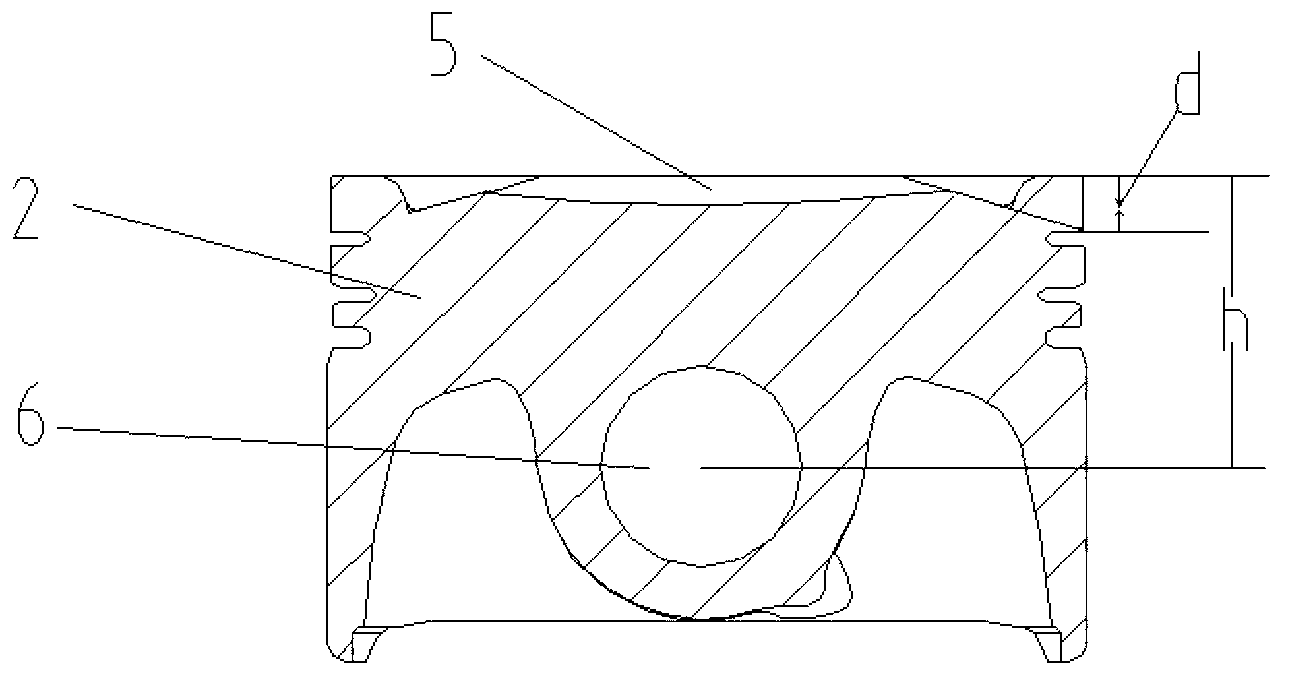

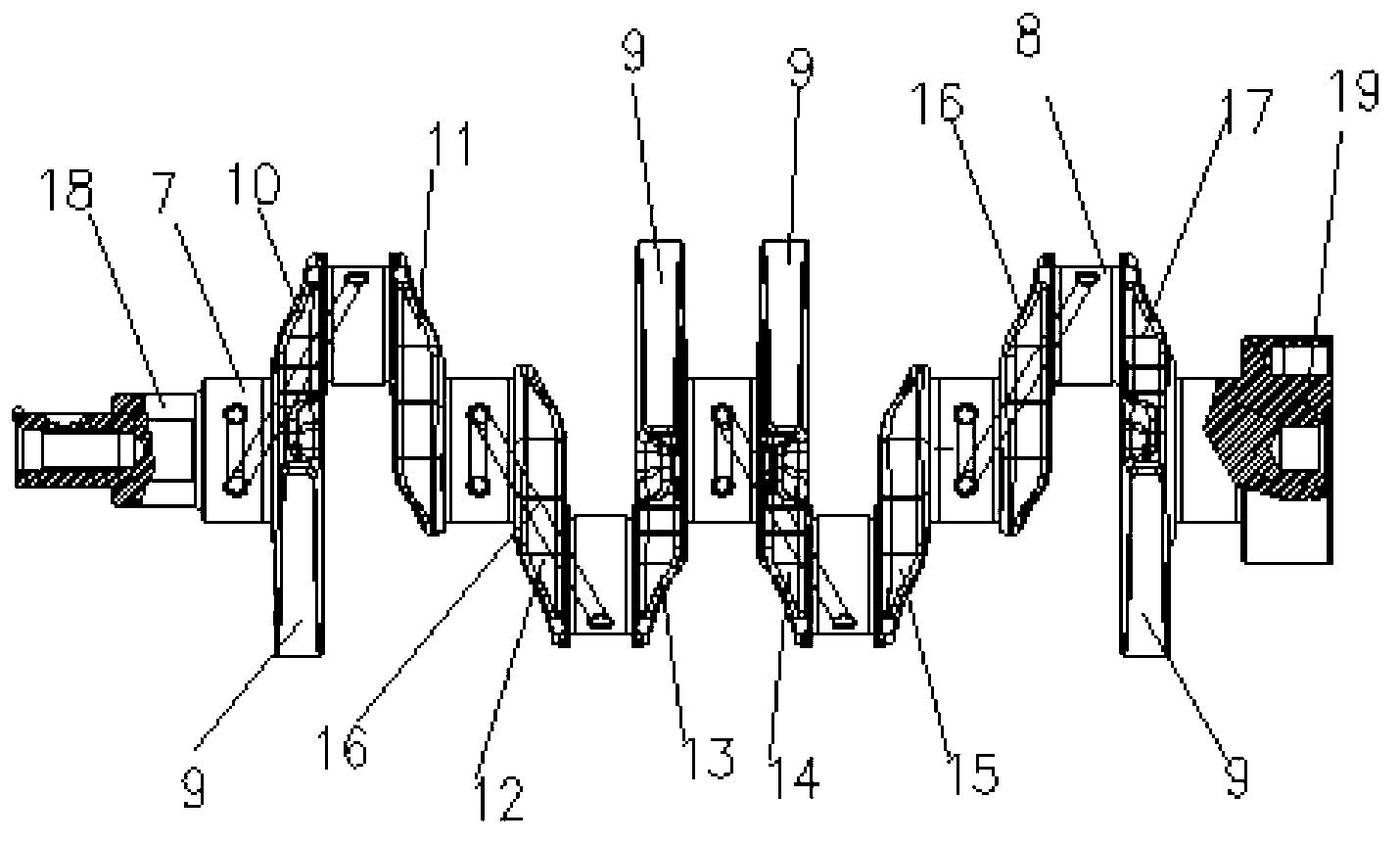

[0023] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 is a schematic diagram of the piston structure, image 3 Schematic diagram of the crankshaft structure, Figure 4 It is a schematic diagram of the connecting rod structure, as shown in the figure: the piston engine crank connecting rod mechanism of this embodiment includes a cylinder 1, a piston 2, a connecting rod 3 and a crankshaft 4, and the top surface of the piston 2 is recessed inwardly and is provided with a bowl-shaped combustion chamber. Pit 5, the top surface of the piston and the piston circumferential side are flat-top structure transitions; the flat-top structure transition refers to the circumferential radial surface of the piston top surface from the upper edge of the combustion pit circumference to the circumferential side of the piston. The sharp edge structure of the corner, and the connection between the top surface of the piston and the side surface of the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com