High temperature vacuum time delay control automatic infusion device and infusion technology

A time delay control, high temperature vacuum technology, applied in the field of vacuum infusion, can solve the problems of difficult to discharge air bubbles, affect the appearance surface and electrical insulation and mechanical properties, air bubbles are not easy to discharge, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

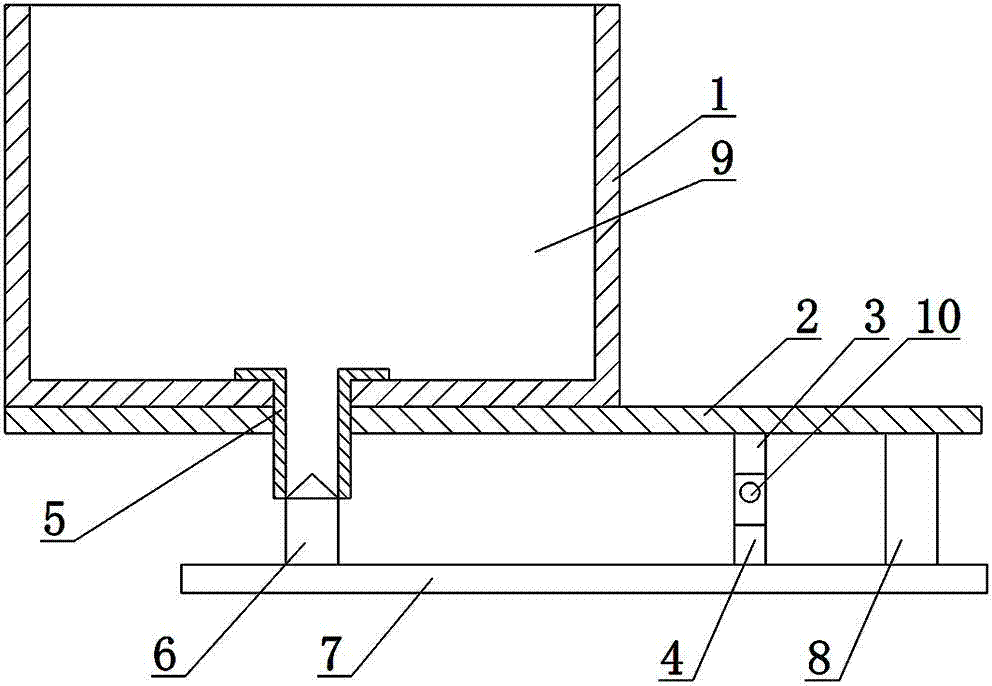

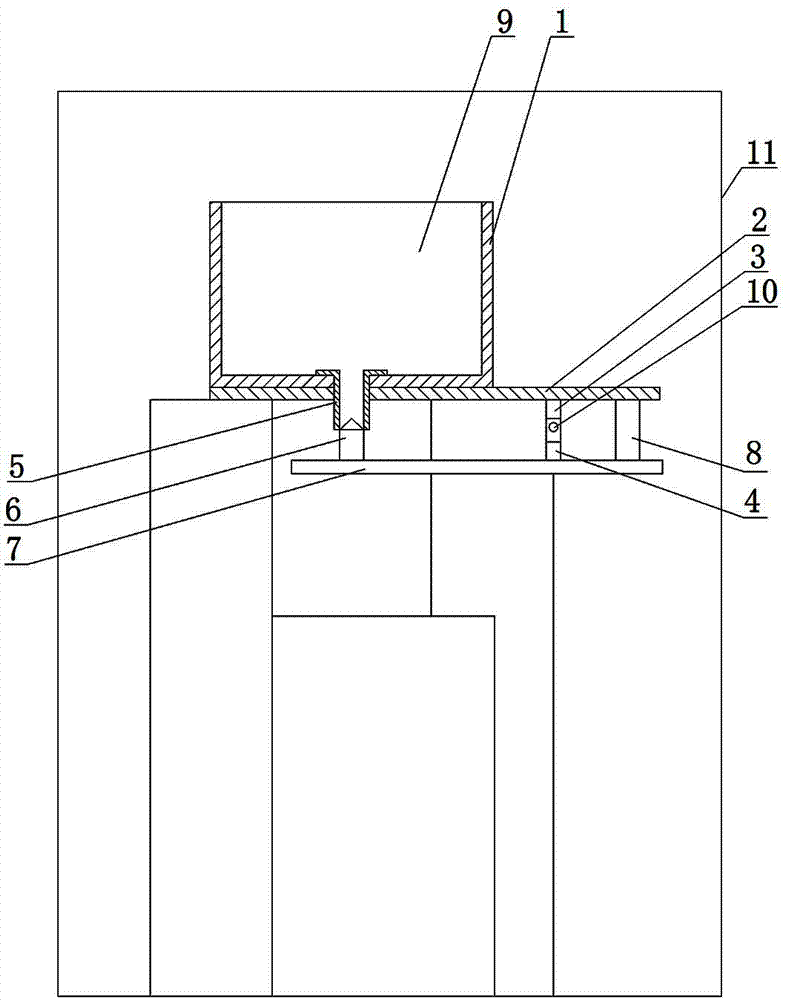

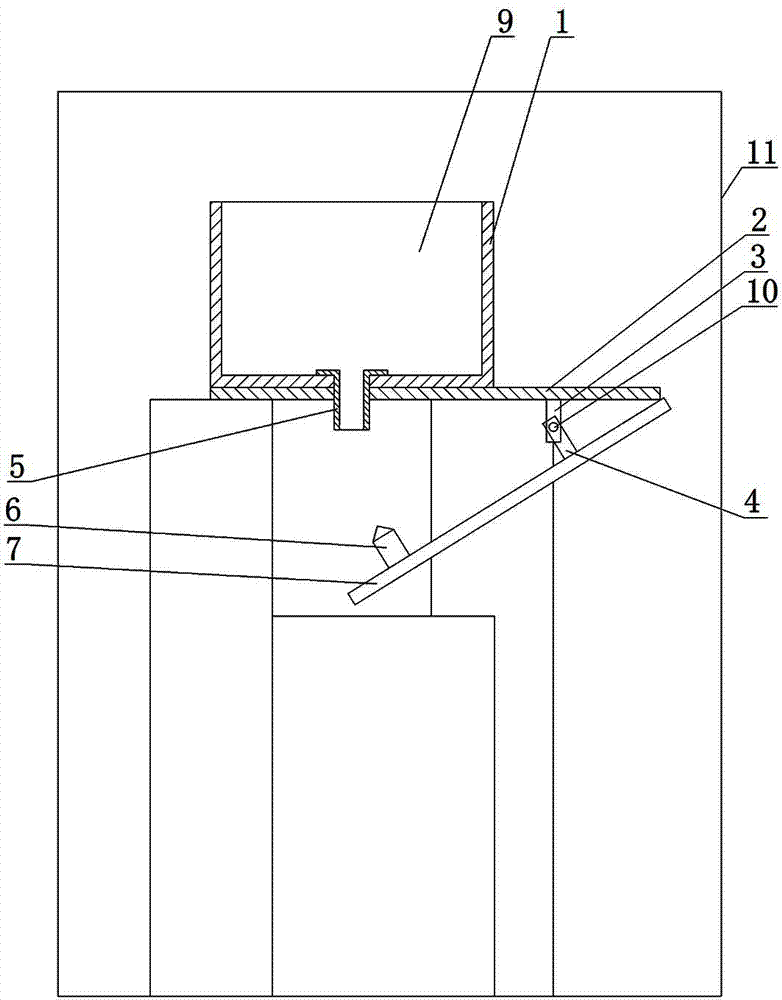

[0023] Such as figure 1 As shown, the high-temperature vacuum delay control automatic filling device includes a stocker 1 with an upper opening, a connecting plate 2, a column A3, a column B4, a leaking nozzle 5, a plug 6, a support plate 7 and an opening switch 8. The inside of the feeder 1 is provided with a cavity 9, and the bottom of the stocker 1 is provided with a leakage nozzle 5, which is fixedly connected with the storage device 1, and the inside of the leakage nozzle 5 is provided with a communication cavity 9 and the external space The connecting plate 2 is set at the bottom of the stocker 1 and is fixedly connected with the stocker 1, the column A3 is fixed on the lower surface of the connecting plate 2, the column B4 is fixed at the middle of the support plate 7, the column A3 and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com