Fluidized bed granulation system

A technology of fluidized bed granulation and fluidized bed cooler, which is applied in the direction of powder suspension granulation, etc., can solve the problems of high engineering investment and high energy consumption of the fluidized bed granulation system, so as to save engineering investment and reduce Equipment investment and energy consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

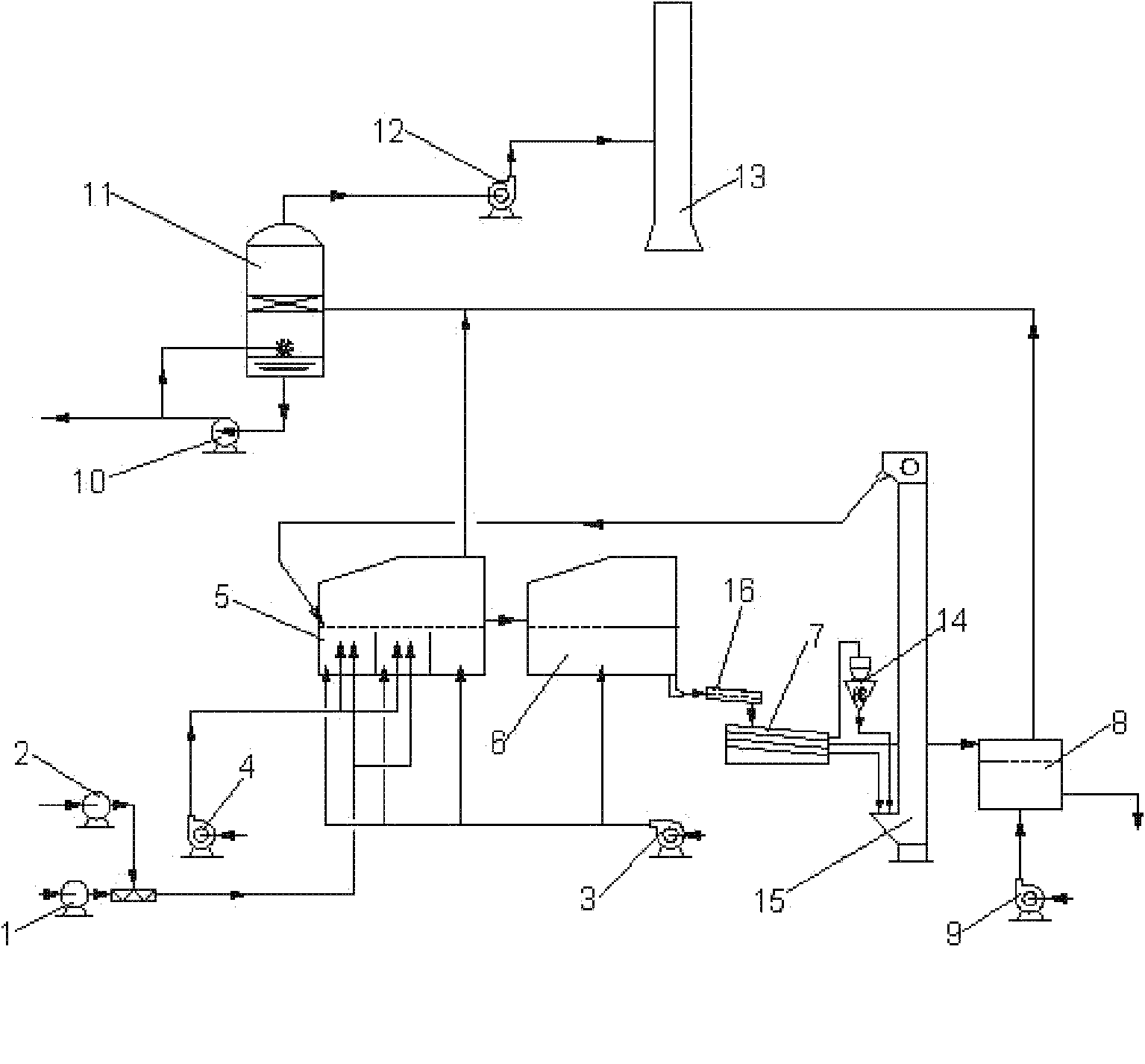

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. The direction of the arrow in the drawings is the direction of material or gas transmission in the system.

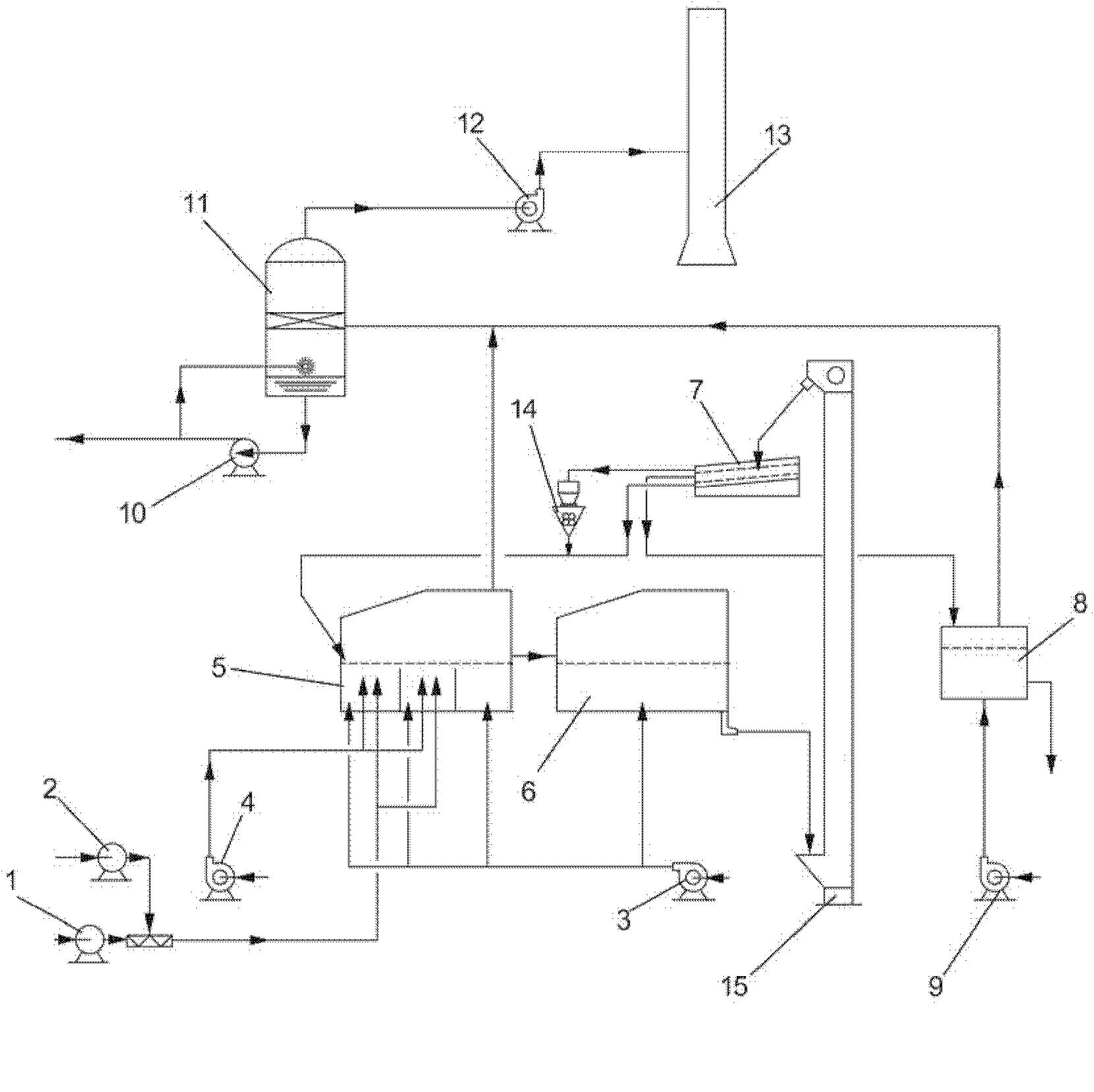

[0021] Such as figure 2 As shown, it is a schematic flow diagram of the fluidized bed granulation system of this embodiment, and the system includes sequentially connected on the process flow: fluidized bed granulator 5, fluidized bed cooler 6, vibrating feeder 16 and screening machine 7; The screening machine 7 includes three screening outlets for large particles, medium particles and small particles; wherein, the particle size of the medium particles is two kinds of 2-4.75mm or 4-8mm, and the large particles and small particles are relative to the medium particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com