Fault-tolerate primary permanent magnetic vernier linear motor

A linear motor, primary technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of double-layer concentrated windings that do not have high fault tolerance, fail to operate with faults, and reduce the use efficiency of permanent magnets. To achieve the effect of simple structure, convenient production of embedded wires, and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

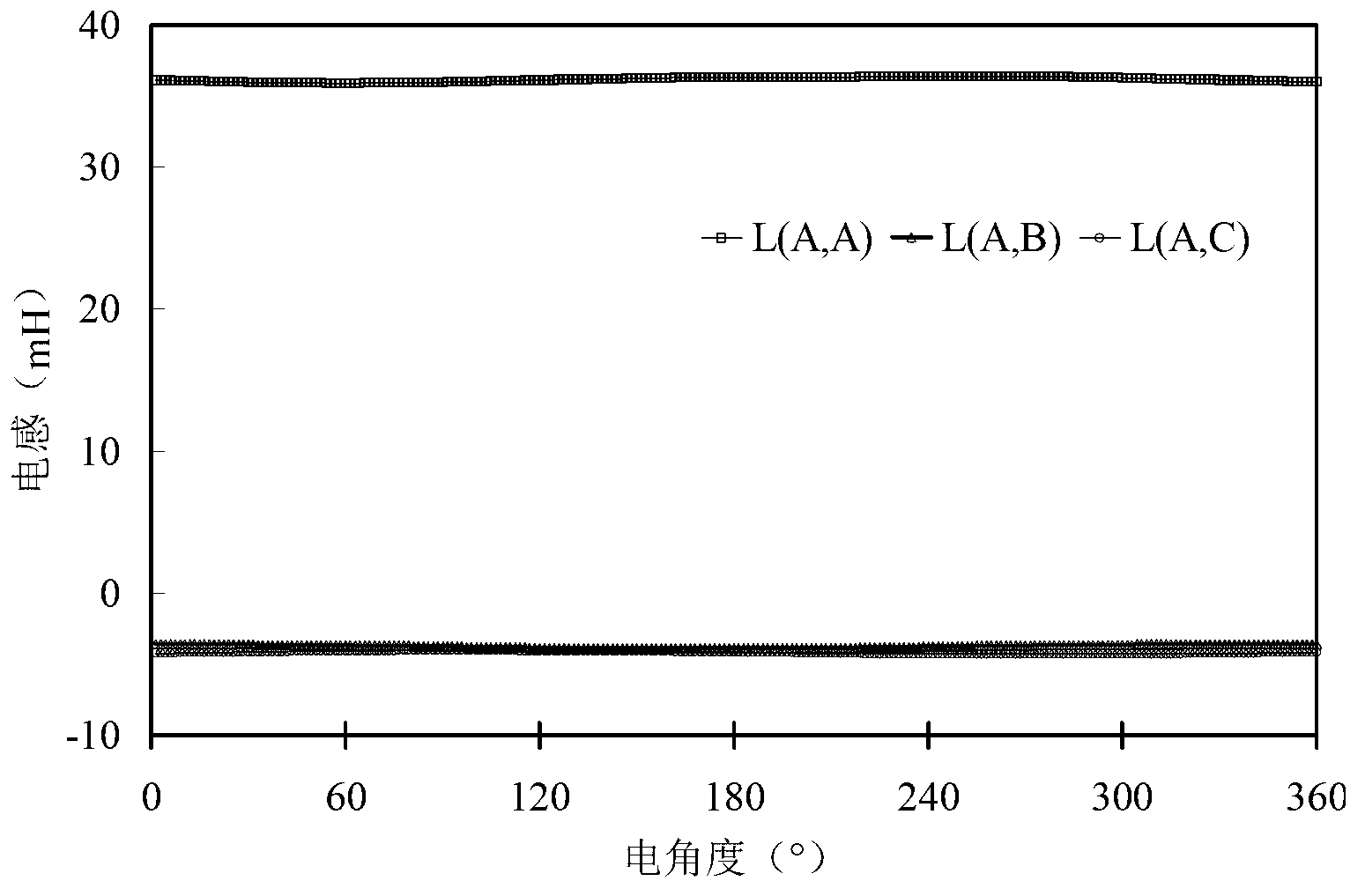

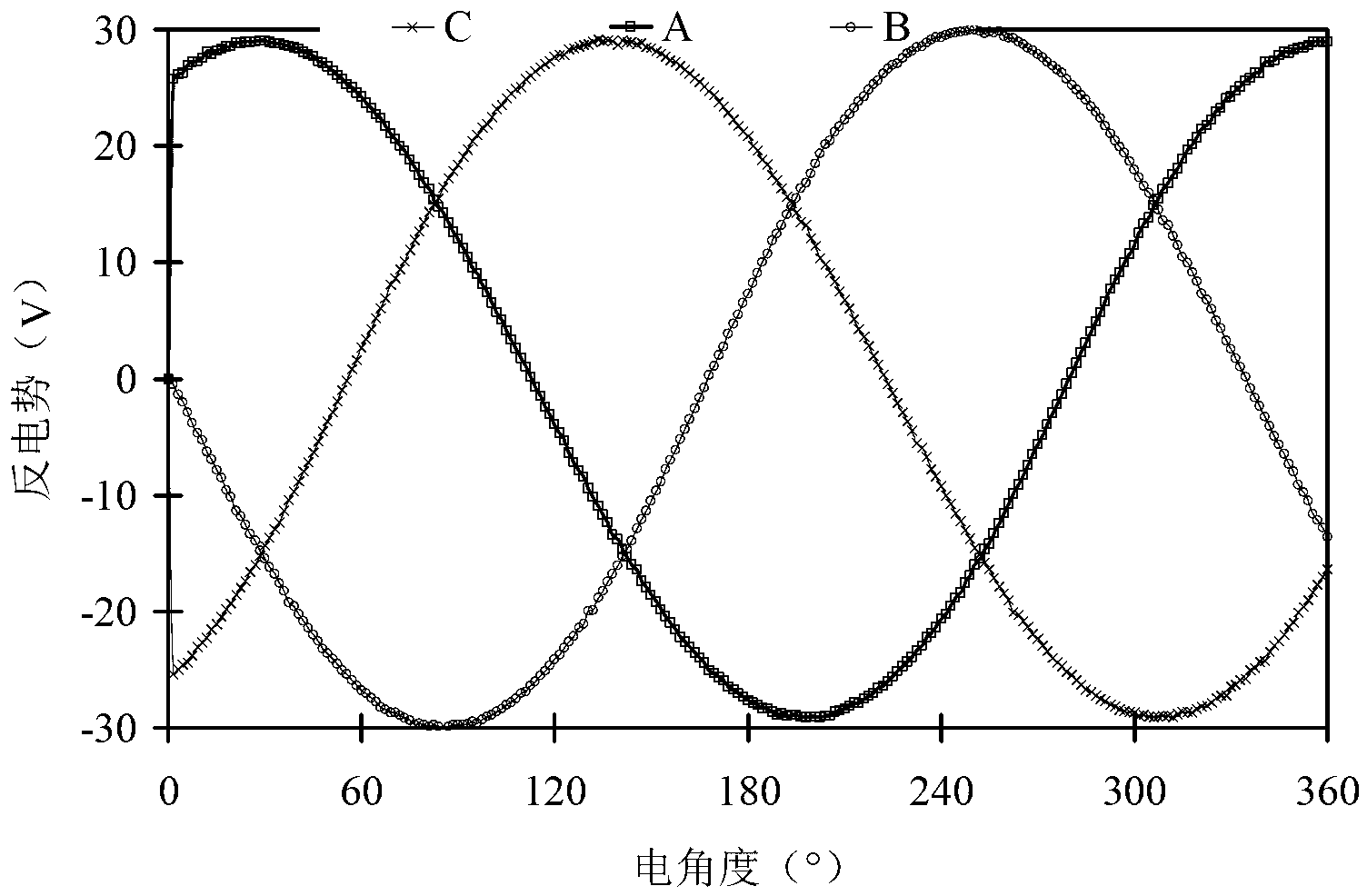

[0023] Such as figure 1 As shown, the present invention consists of a primary 1, a secondary 6, an armature winding 3, a fault-tolerant tooth 4, an armature tooth 2, a permanent magnet 5 attached to the end of the armature tooth 2, and a secondary tooth 7 on the secondary 6. composition. The length of the primary 1 is less than the length of the secondary 6 . The pole distance ratio between primary and secondary satisfies τ s / τ p =k±1 / m, the motor of the present invention takes k=3, m=3. There is an air gap between primary 1 and secondary 6. On the primary 1, the fault-tolerant teeth 4 and the armature teeth 2 are evenly spaced. Five permanent magnets 5 are fixed on the end of each armature tooth 2 in the form of surface mounting, and the magnetization directions N-S and S-N of the five permanent magnets are alternately arranged, and the magnetization direction is parallel to the central axis of the armature tooth 2 . The height of the fault-tolerant tooth 4 is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com