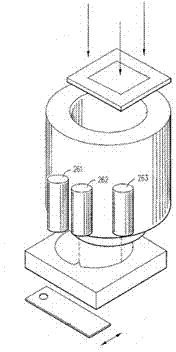

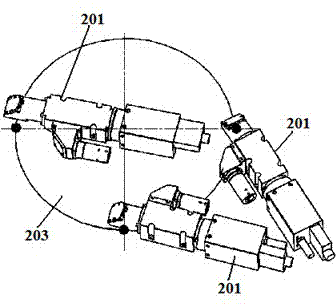

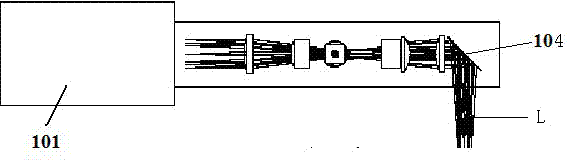

Silicon wafer prealignment measuring apparatus

A measurement device and pre-alignment technology, which is applied in the direction of exposure devices, optics, and instruments in photolithography, can solve problems affecting thermal stability, loose structure layout, and unfavorable component modularization, so as to improve pre-alignment accuracy, Strong structural independence and reduced temperature influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] After Wafer handling transfers silicon wafers through pre-alignment, the eccentricity and deflection are initially compensated. Afterwards, the transfer manipulator continues to transport the silicon wafers to the inside of the lithography machine. The relative drift of the frame will cause a large positional disturbance to the silicon wafers transferred to the handover position of the workbench by Wafer handling. In order to make up for these losses and further improve the accuracy of the wafer, the silicon wafers need to be pre-aligned twice at the handover position. Through the secondary pre-alignment, that is, through the measurement of the pre-alignment measurement device in the present invention, the residual eccentricity and deflection of the silicon wafer are obtained, and the residual error is compensated by the workbench. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com