Cleaning device of heat exchanger

A technology for cleaning devices and heat exchangers, which is applied to cleaning heat transfer devices, flushing, lighting and heating equipment, etc., to achieve the effects of not being prone to secondary pollution, reducing the impact of dirt, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

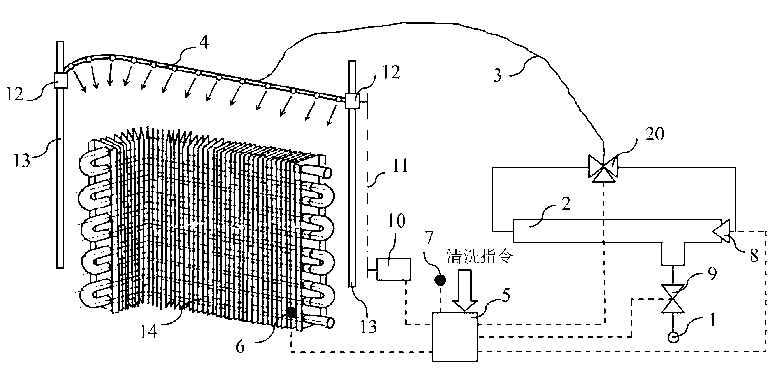

[0020] Such as figure 1 The shown cleaning device applied to the condenser of an air conditioner includes a high-pressure air source 1, a vortex tube 2, a flexible pipeline 3, a nozzle array 4, a controller 5, a dirt sensor 6, an ambient temperature sensor 7, a hot gas end regulating valve 8, Pressure regulating valve 9, stepping motor 10, transmission mechanism 11, slider 12, guide rail 13, air conditioning condenser 14, cooling and heating proportional regulating valve 20, high-pressure air source 1 is maintained by the air conditioner through the interface set in the outdoor unit shell of the air conditioner The air compressor carried by the technician is provided. The high-pressure air source 1 enters the vortex tube 2, and separates the cold and hot air flows in the vortex tube 2. The temperature, pressure and flow rate of the pressure air at the cold and hot ends of the vortex tube 2 pass through the hot air The end regulating valve 8 and the pressure regulating valve 9 re...

Embodiment 2

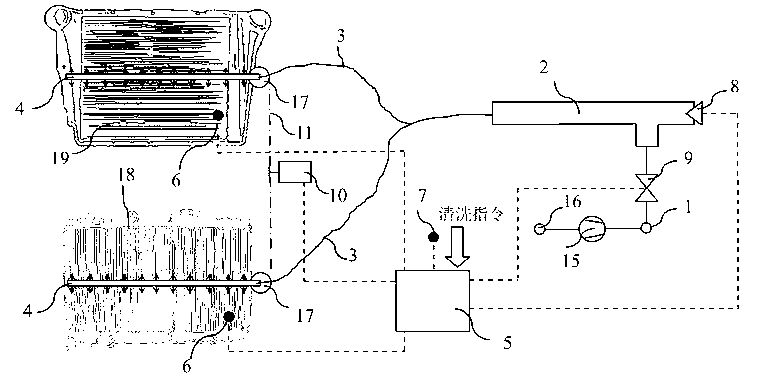

[0022] Such as figure 2 The shown cleaning device applied to the vehicle cooling system includes a high-pressure air source 1, a vortex tube 2, a flexible pipe 3, a nozzle array 4, a controller 5, a dirt sensor 6, an ambient temperature sensor 7, a hot gas end regulating valve 8, Pressure regulating valve 9, stepping motor 10, transmission mechanism 11, air compressor 15, air source 16, rotating shaft 17, radiator 18 and intercooler 19. The vehicle cooling system is composed of radiator 18 and intercooler 19. The compressor 15 is powered by a vehicle engine or a turbine that uses vehicle exhaust energy. The air compressor 15 compresses air from an air source 16 as a high-pressure air source 1 and supplies it to the vortex tube 2. The high-pressure air source 1 enters the vortex tube 2 and is connected to the vortex tube 2. The temperature, pressure and flow rate of the cold end pressure air of the vortex tube 2 are controlled by the hot end regulating valve 8 and the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com