Air pressure control gas flow type diesel/LPG mixed combustion system

A liquefied petroleum gas and gas flow technology, which is applied in the direction of charging system, engine control, combustion engine, etc., can solve the problems of time-consuming maintenance and expensive production cost, and achieve fuel cost saving, low production cost and broad market application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

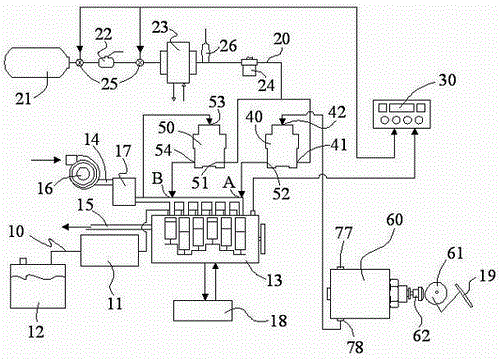

[0051] The specific structure of a preferred embodiment of the air pressure controlled gas flow type diesel / liquefied petroleum gas mixed combustion system of the present invention is as follows figure 1 shown. The diesel / liquefied petroleum gas mixed combustion system includes a diesel oil delivery pipeline 10 and a liquefied petroleum gas delivery pipeline 20 , and an oil-gas conversion switch 30 is used to switch between different fuels for combustion operation.

[0052] The center of the diesel delivery pipeline 10 is a diesel injection pump 11 , one end of the diesel delivery pipeline 10 is connected to a diesel oil tank 12 , and the other end is communicated with a diesel engine 13 . When the diesel engine 13 is activated, a user steps on the accelerator pedal 19 to determine that the diesel injection pump 11 draws a proper amount of diesel from the diesel fuel tank 12 and enters the multiple cylinders inside the diesel engine 13 .

[0053] The diesel engine 13 is exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com