Diesel oil/liquefied petroleum gas co-firing system

A technology for liquefied petroleum gas and diesel, which is applied in the charging system, oil supply device, combustion engine, etc., which can solve the problems of high production cost and time-consuming return to the factory for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to make readers deeply understand the essence of the present invention, in conjunction with the necessary accompanying drawings, the technical content of the present invention is detailed and specifically stated as follows:

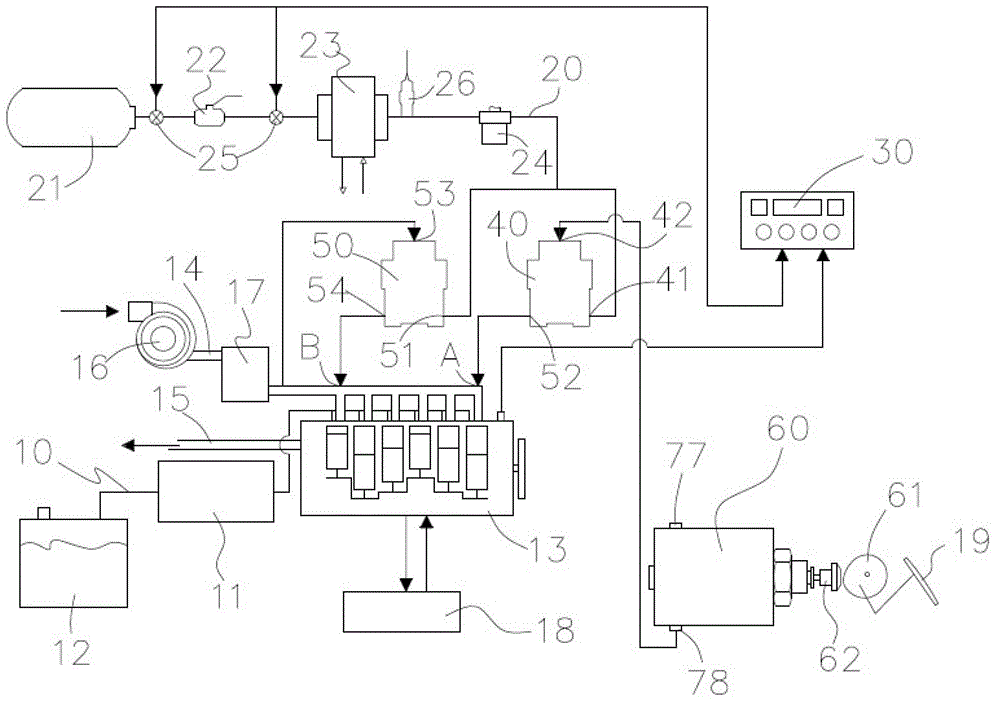

[0103] exist figure 1 In the paper, the specific architecture of a preferred embodiment of the air pressure controlled gas flow type diesel / liquefied petroleum gas mixed combustion energy saving and carbon reduction system is clarified.

[0104] This dual-fuel mixed combustion system includes a diesel delivery pipeline 10 and a liquefied petroleum gas delivery pipeline 20 , and an oil-gas switch 30 is used to switch between different fuels for combustion operation.

[0105] The center of the diesel delivery pipeline 10 is a diesel injection pump 11 , one end of the diesel delivery pipeline 10 is connected to a diesel oil tank 12 , and the other end is communicated with a diesel engine 13 . When the diesel engine 13 is activated, a user de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com