A retractable spring stop fitting for a seat recliner

A seat recliner and retractable technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of large space size, poor synchronization, and unusable springs, etc., to achieve improved locking strength, Simplified structure, direct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

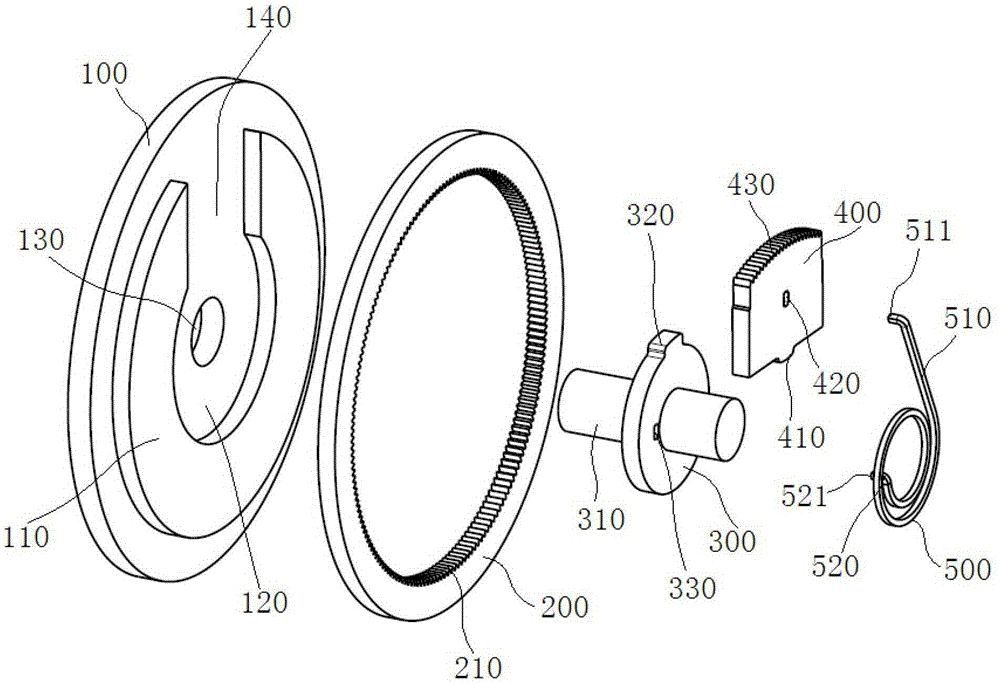

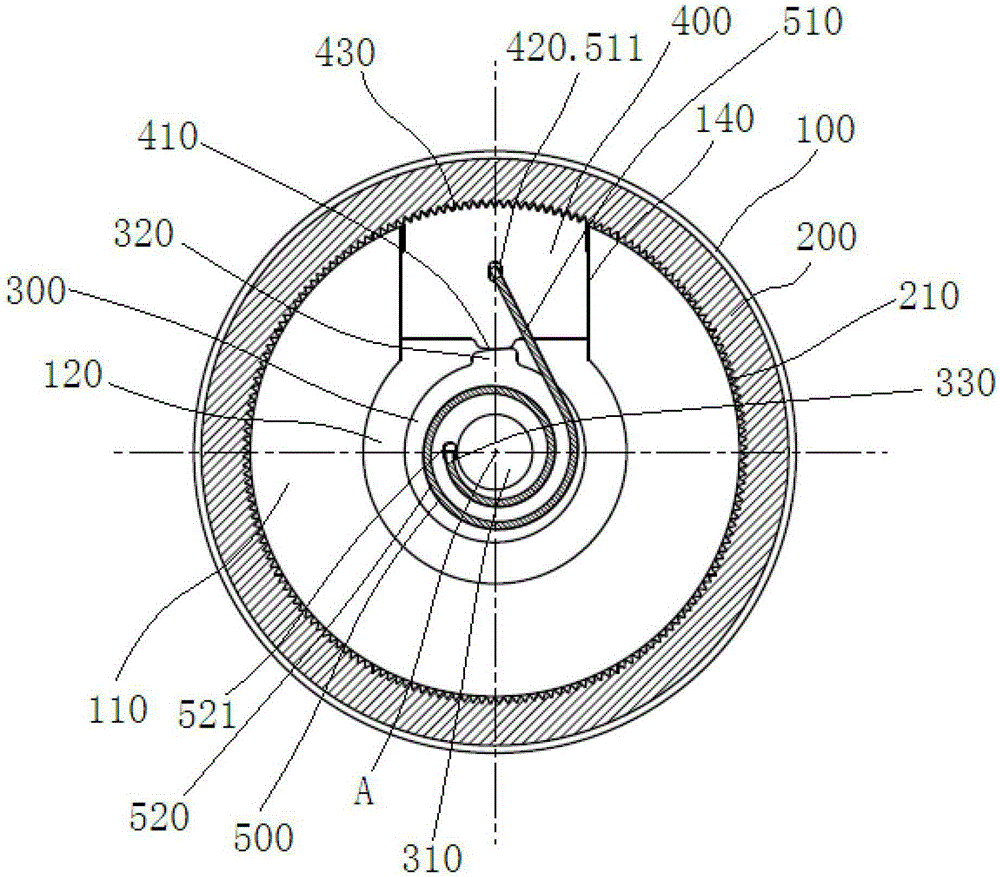

[0053] see figure 1 and figure 2 , a retractable spring stop fitting for a seat recliner is shown in the figure, which includes a main board 100 installed on the seat cushion side and a toothed plate 200 installed on the backrest side. Of course, the main board can also be installed as required 100 is installed on the backrest side, and the tooth plate 200 is installed on the seat cushion side.

[0054] The gear plate 200 has an inner ring gear 210 so that the gear plate 200 is locked on the main board 100 without rotation.

[0055] On the surface of the main board 100 opposite to the side of the tooth plate 200, an annular guide 110 protruding into the ring gear 210 is provided. In the center of the annular guide 110, there is an inner chamber 120 for the rotation of the cam 300. A shaft hole 130 for inserting the inner end of the camshaft 310 is defined in the center of the inner chamber 120 . A channel 140 for the radial movement of the lock plate 400 is provided on the...

Embodiment 2

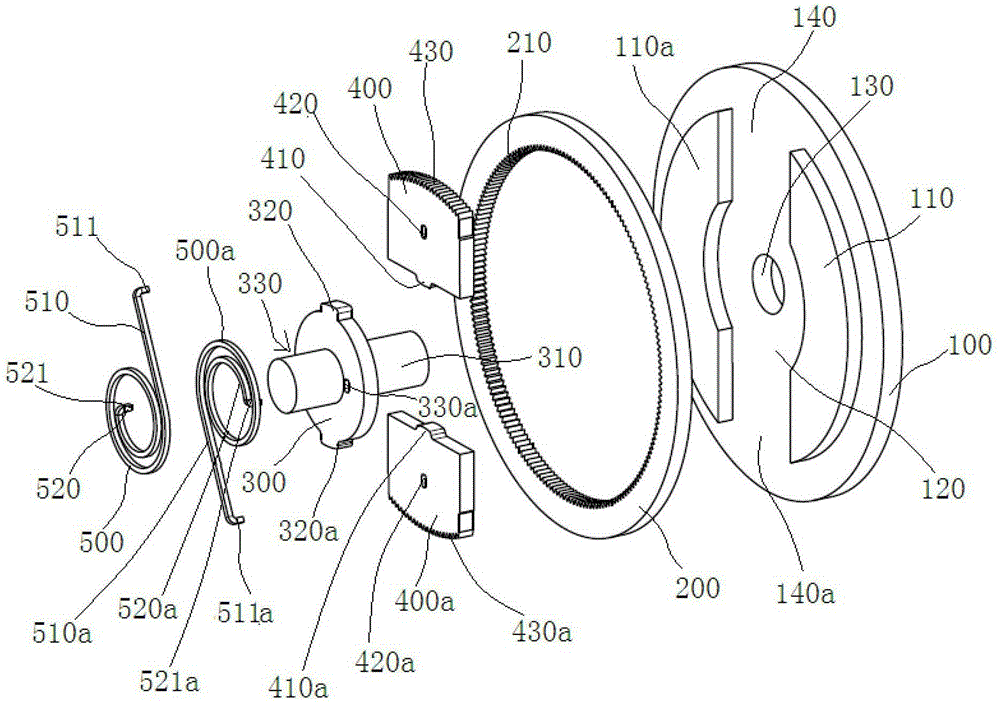

[0062] see image 3 and Figure 4 , a retractable spring stop fitting for a seat recliner is shown in the figure, which includes a main board 100 installed on the seat cushion side and a toothed plate 200 installed on the backrest side. Of course, the main board can also be installed as required 100 is installed on the backrest side, and the tooth plate 200 is installed on the seat cushion side.

[0063] The gear plate 200 has an inner ring gear 210 . On the surface of the main board 100 opposite to the side of the gear plate 200, two guides 110, 110a extending into the inner ring gear 210 are arranged mirror-symmetrically. The cavity 120 is provided with a shaft hole 130 for inserting the inner end of the camshaft 310 in the center of the cavity 120 . Channels 140, 140a for the radial movement of the two locking plates 400, 400a are arranged in front of the two guides 110, 110a, and the channels 140, 140a are distributed at 180°.

[0064] The locking plates 400, 400a are ...

Embodiment 3

[0071] see Figure 5 and Figure 6 , the difference between a retractable spring stop fitting for a seat recliner given in the figure and Embodiment 2 is that the two retractable springs 500, 500a are integrated into one retractable spring 500', which surrounds the The camshaft 310 of the cam 300 is on the outer end, that is, around the axis A of the cam 300 .

[0072] The retractable spring 500' has a straight middle part 520' and two outer ends 511', 512', the outer end 511' extends obliquely upward in a straight line, and the outer end 512' extends obliquely downward in a straight line, The retractable spring 500' is wound by spring steel wire or directly fine punched by spring steel plate. The ends of the outer ends 511', 512' of the retractable spring 500' are bent toward the lock plates 400, 400a to form an outer hook 511a', 512a', and the outer hooks 511a', 512a' are respectively hooked into the lock plate 400 , 400a in holes 420, 420a.

[0073] A groove 311 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com