Welding fixture for formula racing

A formula racing car and welding jig technology, which is applied in the field of formula racing welding jigs, can solve the problem that the quality of the car body is far from the design requirements, and achieve the effects of strong reusability, reliable function, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described below with reference to the accompanying drawings.

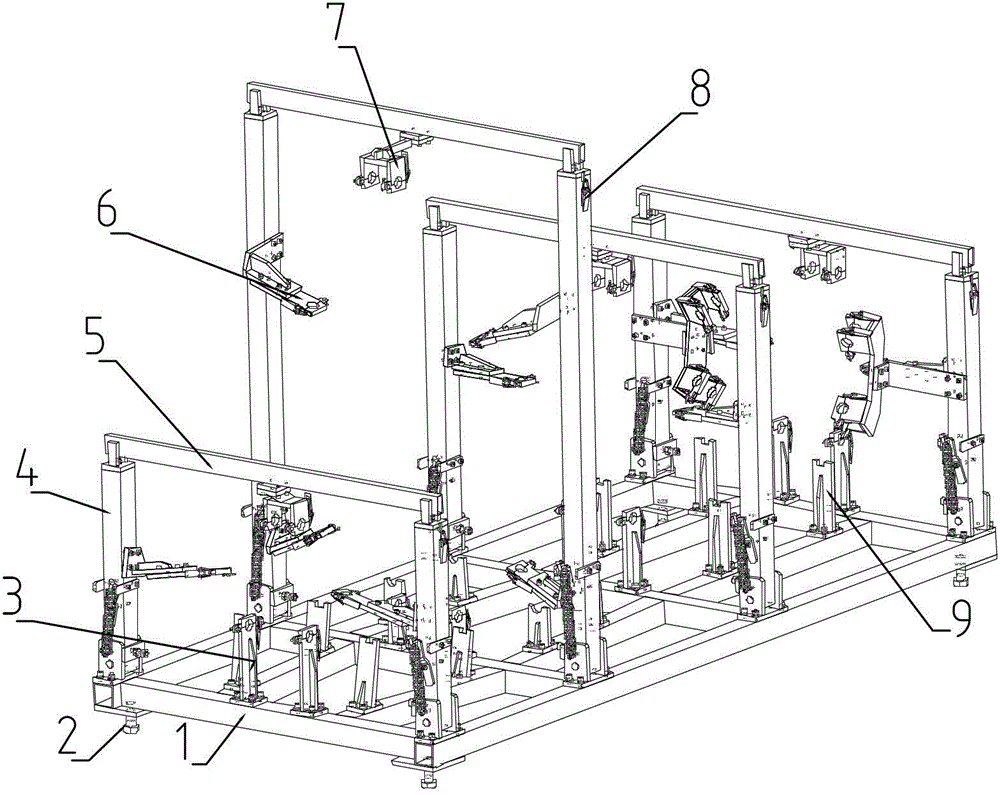

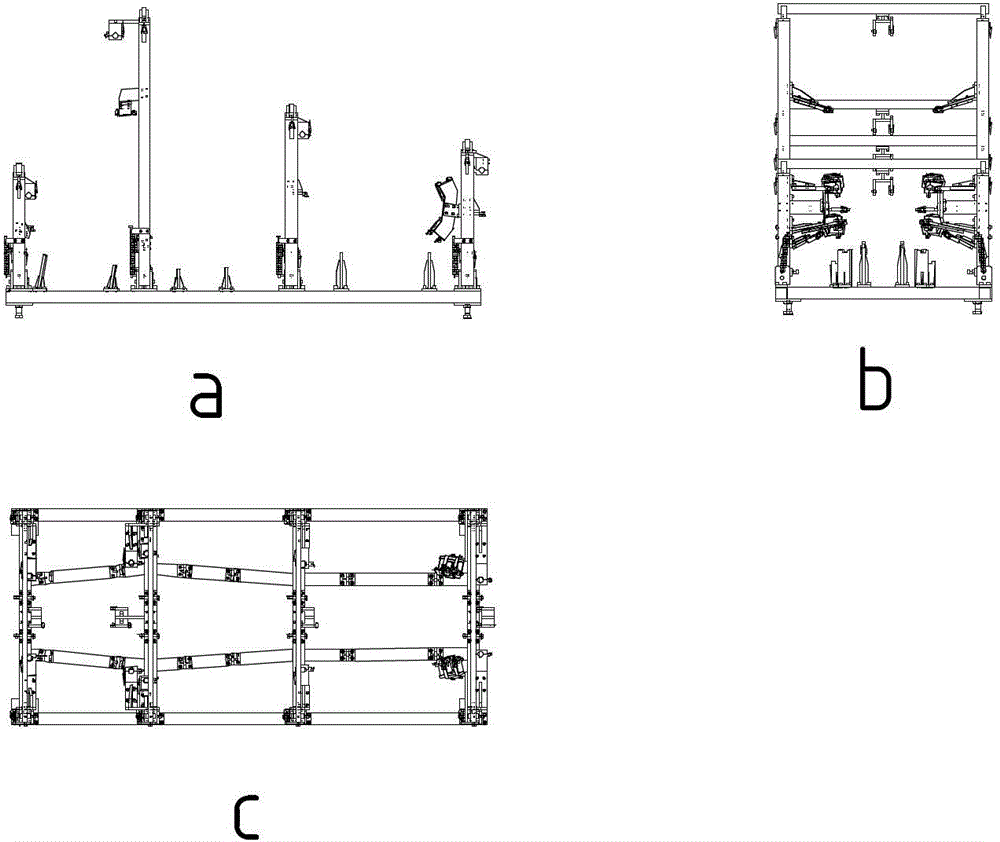

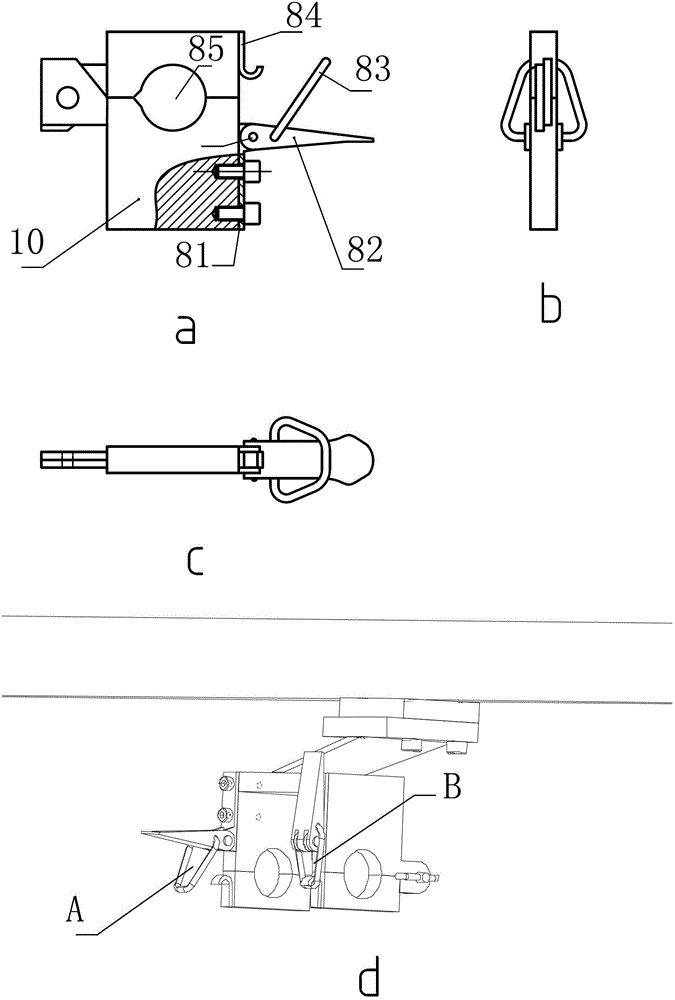

[0035] like figure 1 and 2 As shown, the formula racing welding fixture according to the present invention includes a flexible base 1, a horizontal adjustment bolt 2 fixedly installed on the flexible base 1, a main positioning clamping unit 3 and an auxiliary positioning unit 9, and a column with limiting and safety functions Mechanism 4, the top positioning beam 5 connected with the column mechanism 4, the side positioning clamping unit 6 fixedly installed on the column mechanism 4, and the upper positioning clamping unit 7 fixedly installed on the top positioning beam 5.

[0036] The main positioning and clamping unit 3 , the auxiliary positioning unit 9 , the side positioning and clamping unit 6 and the upper positioning and clamping unit 7 can all move on the flexible base 1 , the column mechanism 4 and the top positioning beam 5 .

[0037] Among them, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com