Automobile testing fixture quantitatively-adjustable movable reference mechanism and adjusting method

A technology of quantitative adjustment and inspection tools, which is applied in the direction of measuring devices, adopting mechanical devices, mechanical measuring devices, etc., can solve problems such as inability to use, influence on the stability of parts, and inability to obtain correct values in part springback measurement, so as to achieve integrity High, high stability, avoid interference possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

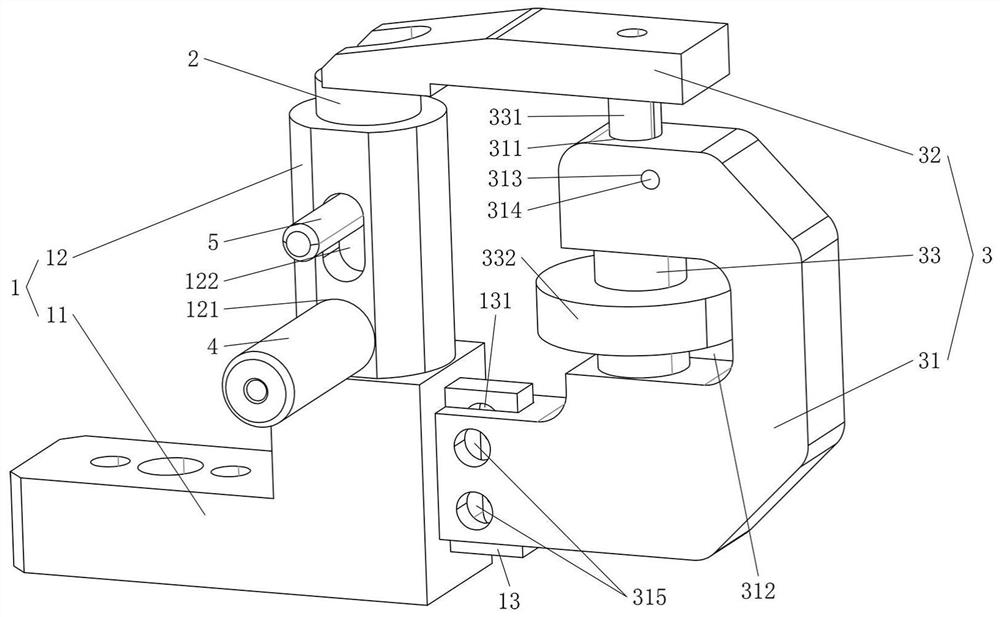

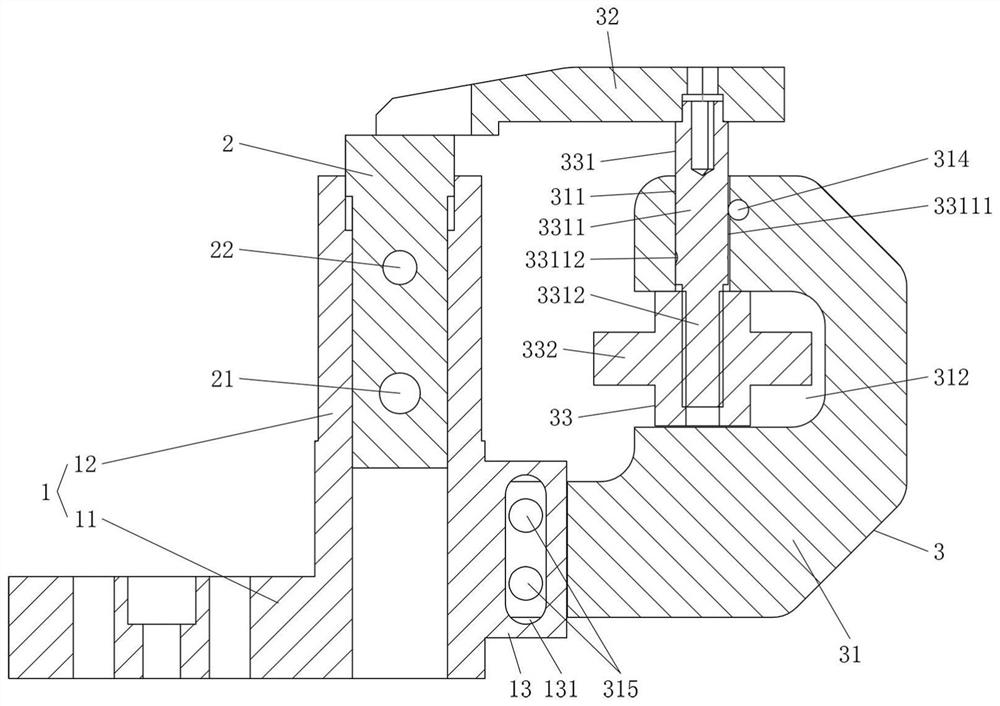

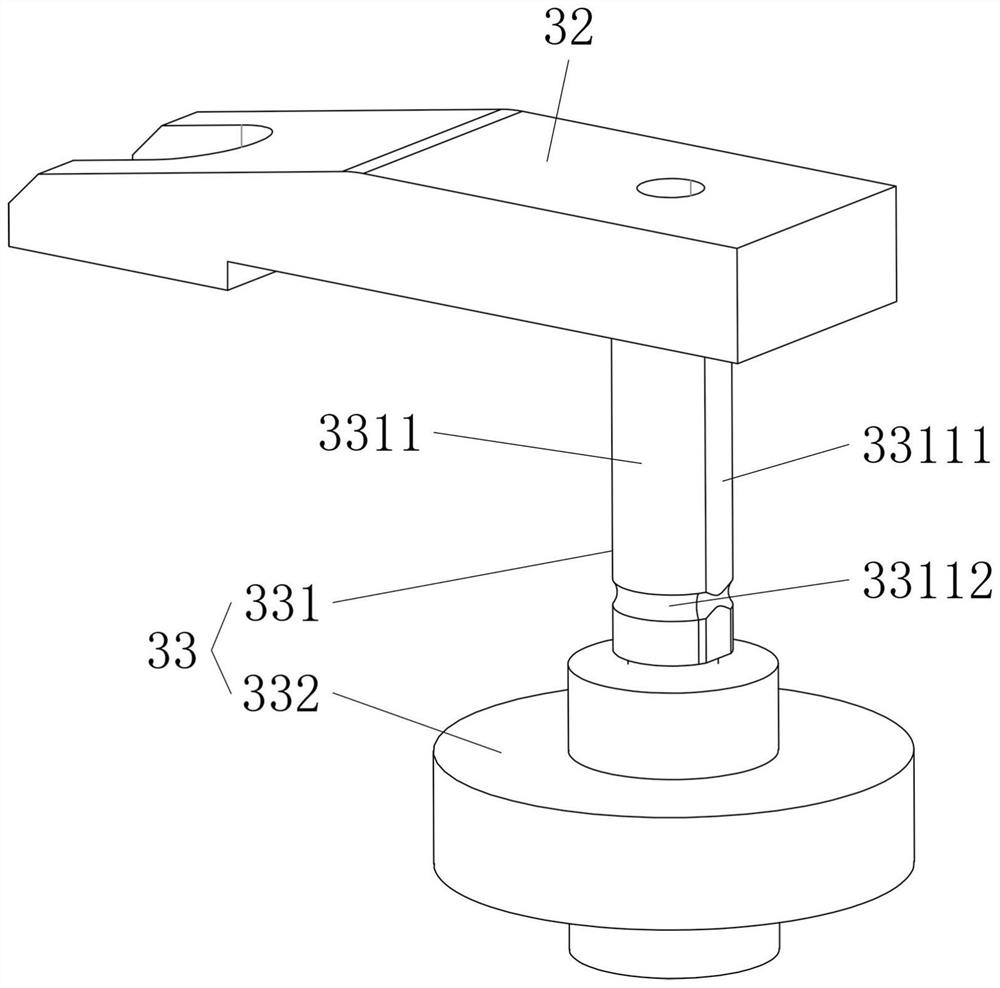

[0051] Such as figure 1 , figure 2 , image 3 , the automobile inspection tool can quantitatively adjust the activity reference mechanism and adjustment method, including:

[0052] The reference pin mounting seat 1, the reference pin mounting seat 1 includes a fixed base 11 and a mounting column 12 located above the fixed base 11 and integrally connected with the fixed base 11, and the side of the fixed base 11 is provided with a chuck assembly connecting piece 13;

[0053] The reference pin 2, the reference pin 2 is installed at the mounting post 12;

[0054] The collet assembly 3, the collet assembly 3 includes a collet mounting seat 31, a collet 32 and a collet driving mechanism 33, the collet mounting seat 31 is connected with the collet assembly connecting piece 13, and the collet 32 is located above the collet mounting seat 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com