Packaging structure shared by heat dissipation channel and ground wire channel in three-dimensional packaging

A heat dissipation channel, three-dimensional packaging technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of difficult management of heating areas, difficult grounding, no heat dissipation path, etc., to improve heat dissipation and grounding effects, reduce packaging costs, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

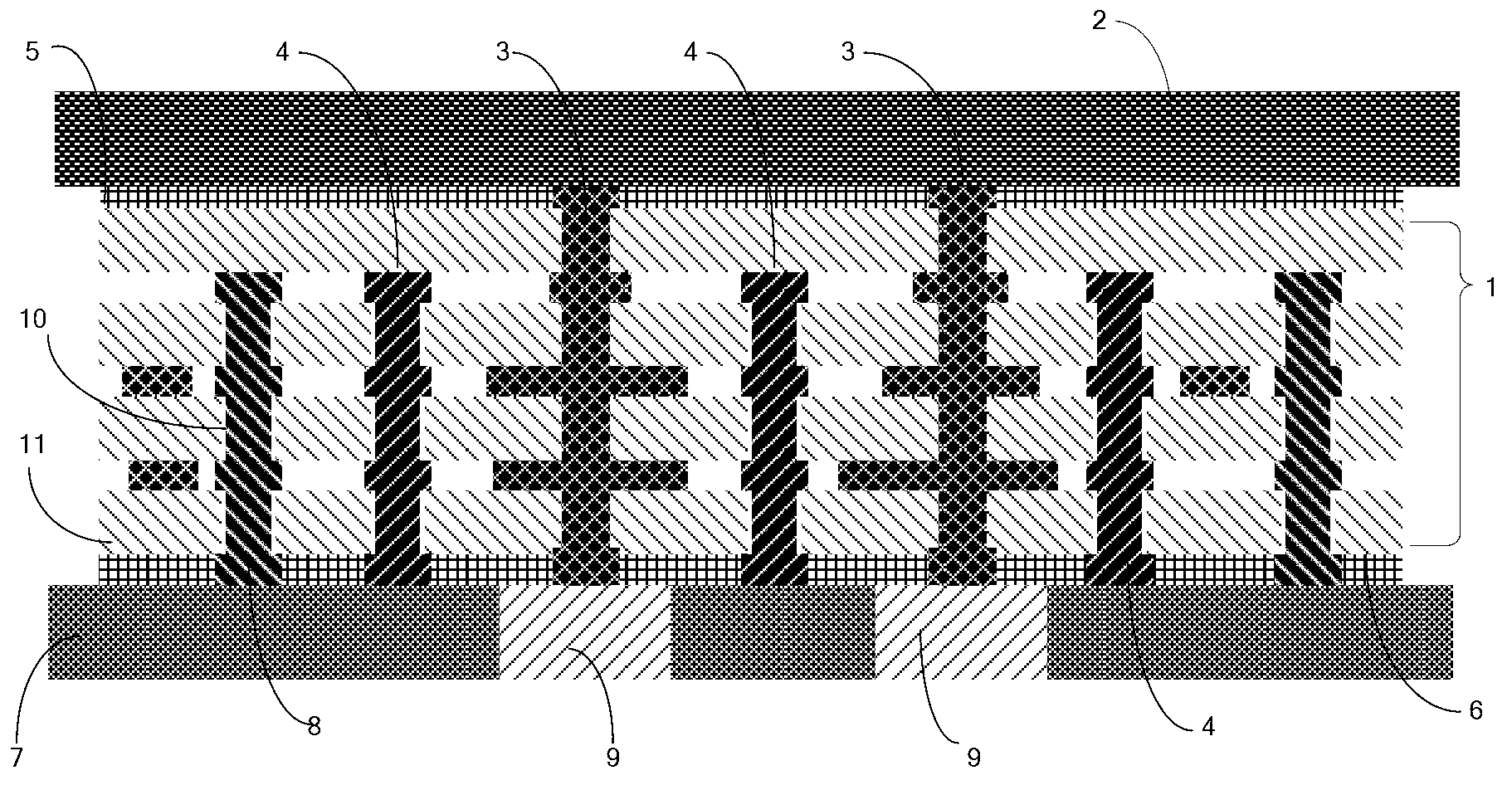

[0015] like figure 1 As shown: in order to improve the heat dissipation and grounding effect in the three-dimensional packaging without increasing the packaging area, the present invention includes a chip 1, and the chip 1 includes a substrate 11, and the substrate 11 includes power connection holes, heat dissipation Ground hole and signal connection hole; the power connection hole is filled with a power connection conductor 8, the heat dissipation ground hole is filled with a heat dissipation ground conductor 3, and the signal connection hole is filled with a signal connection conductor 4, and the power connection conductor 8 passes through the power supply The insulating layer 10 in the connection hole is insulated and isolated from the substrate 11, and the signal connection conductor 4 is insulated and isolated from the substrate 11 through the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com