Engine test inlet pressure closed-loop adjustment system and method

A closed-loop adjustment and inlet pressure technology, applied in the direction of electric fluid pressure control, etc., can solve the problems of low precision and large time lag, and achieve the effect of risk dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

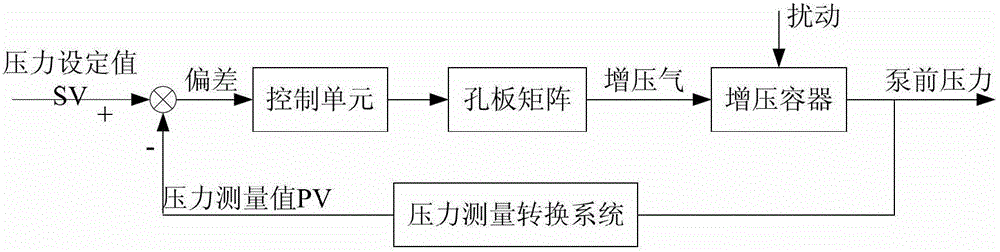

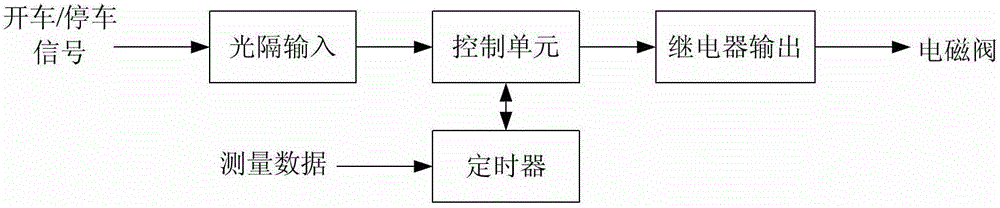

[0038] To realize the closed-loop adjustment of the engine pump inlet pressure, the following problems need to be solved: the real-time control method of the engine pump inlet pressure, the real-time acquisition of the pump inlet pressure measurement data, and the rapid and continuous adjustment of the actuator.

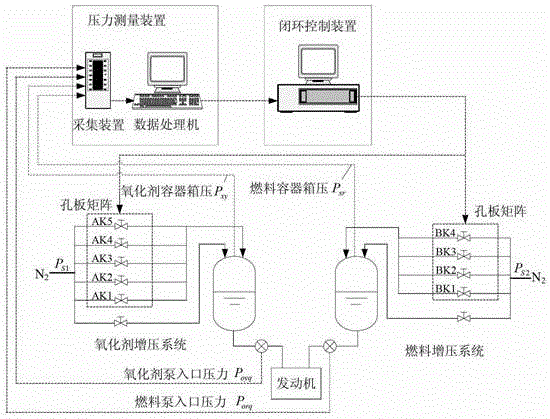

[0039] The principle diagram of the engine test inlet pressure closed-loop adjustment system of the present invention is as follows figure 1 As shown, it includes fuel pressurization system, oxidant pressurization system, fuel container box, oxidant container box, pressure measurement device and closed-loop control device; the fuel container box and oxidant container box are connected to the engine, and the output end of the fuel pressurization system is connected to the The fuel container box is connected, and the output end of the oxidant pressurization system is connected with the oxidant container box; the pressure measurement device includes an interconnected acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com