Furnace type cooling and heat exchange device for sintered ores

A technology of heat exchange device and mine furnace, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of rapid decay of waste heat utilization efficiency, low flue gas temperature, low waste heat utilization efficiency, etc., and avoid flue gas temperature and flue gas volume. Fluctuation of flue gas, increasing flue gas temperature, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

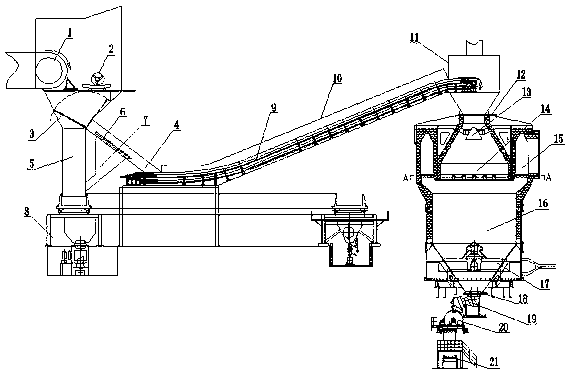

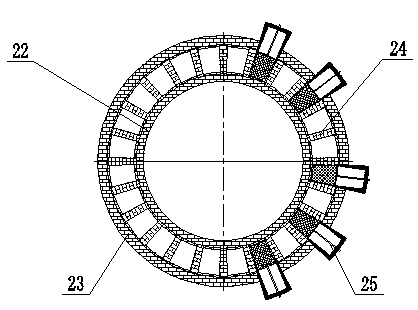

[0014] Such as figure 1 and figure 2 As shown, a sinter furnace type cooling heat exchange device includes a sintering machine 1, a single roll crusher 2, a flap valve 3, a thermal vibrating screen 6, a chain plate conveyor 9, a material distribution device 13, a cooling furnace, and an air distribution device 17. Discharging device and belt conveyor 21, the outlet of the sintering machine 1 is provided with a single-roll crusher 2, the bottom of the single-roll crusher 2 is provided with a flap valve 3, and the bottom of the flap valve 3 is arranged in the chute of the furnace cooling system 4 and the chute 5 of the ring cooling / band cooling system, the flap valve 3 can switch between the chute 4 of the furnace cooling system and the chute 5 of the ring cooling / band cooling system; The bottom of the heat vibrating screen 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com