Method for supporting framework of concrete beam through suspension truss

A technology of concrete beam and formwork support method, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the problems of high labor intensity, increased difficulty of floor-standing steel pipe support construction, and deformation of pillars, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Taking pouring concrete beams as an example, the specific implementation steps are as follows:

[0029] a) Design and fabrication of trusses and steel corbels

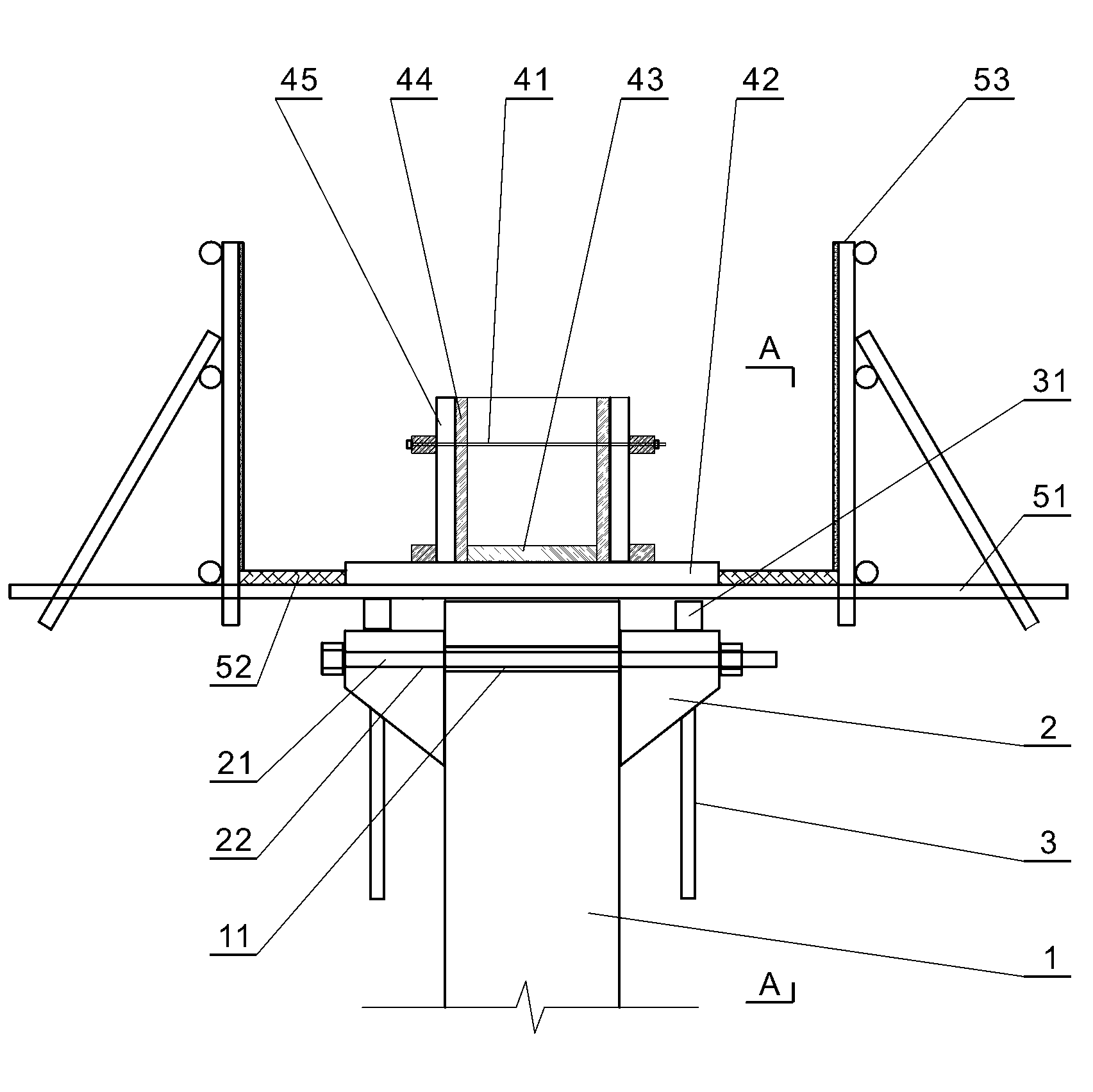

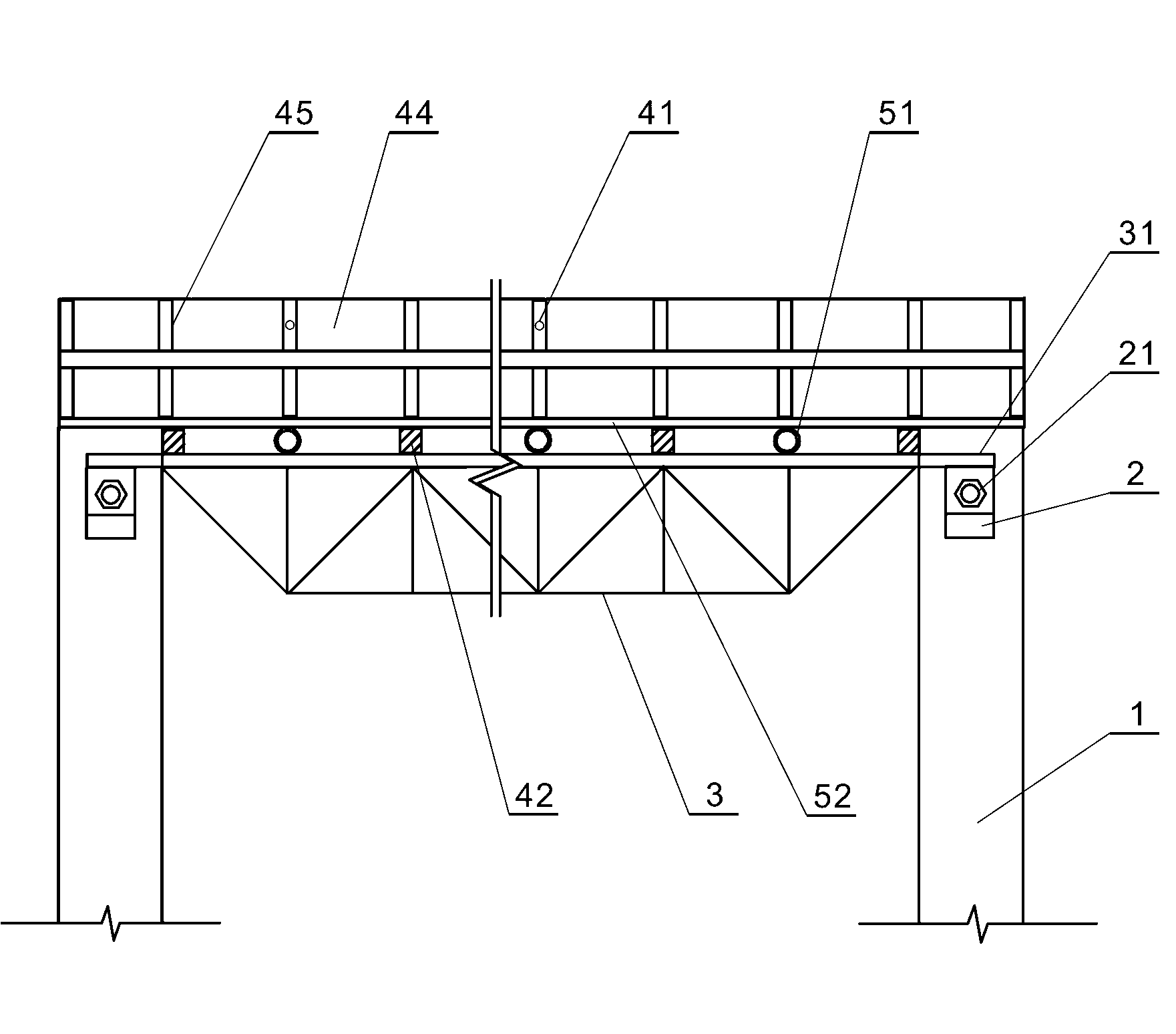

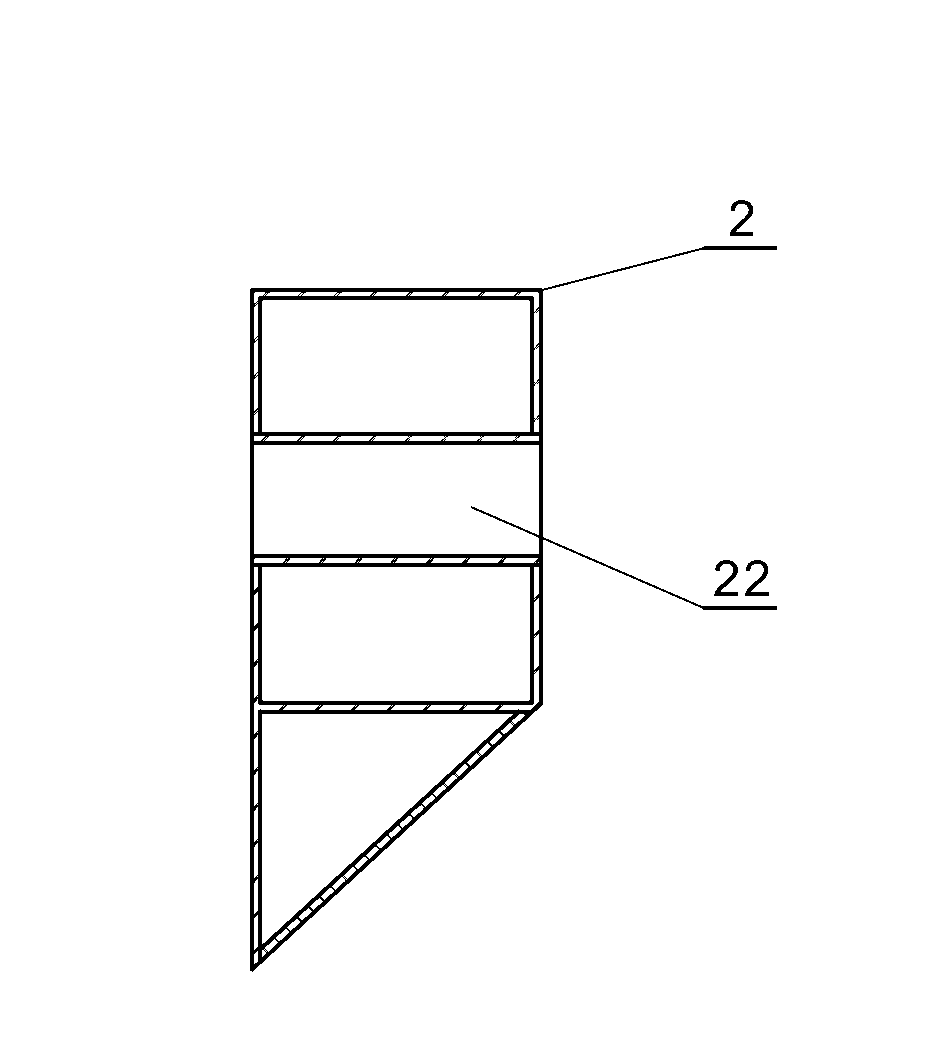

[0030] refer to image 3 , Figure 4 and Figure 5 According to the self-weight of the concrete beam, the gravity of the formwork support, the gravity of the operation platform and the comprehensive elements of the construction load, the load force analysis of the truss 3 and the steel corbel 2 is carried out, the construction drawings of the truss 3 and the steel corbel 2 are designed, and the truss 3 is implemented. and the production of steel corbel 2;

[0031] b), vertical support selection

[0032] refer to figure 1 and figure 2 , select two columns 1 as the two supporting points of the cast-in-situ concrete beam, and reserve bolt holes 11 on the columns 1 by adopting the method of embedded steel casing; the position of the bolt holes should meet the installation design requirements of the truss;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com