Follow-up sewage tank with membrane sealing cover

A sewage tank and follow-up technology, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of non-walking equipment exposed to the outside of the cover, prone to failure, and shortened service life, so as to facilitate workers to operate , extended service life, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings.

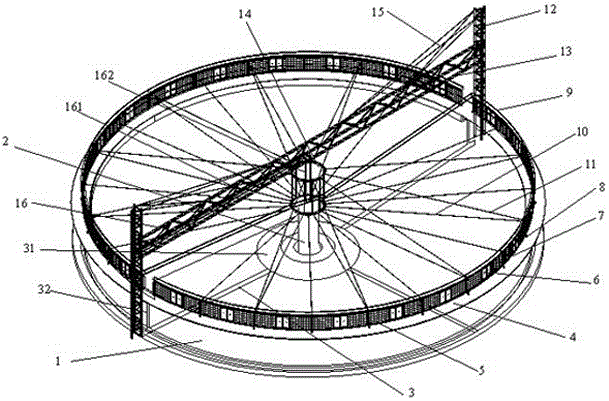

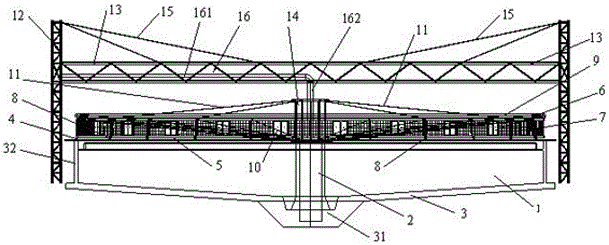

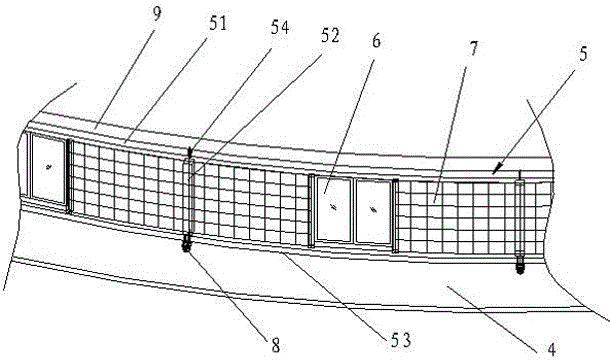

[0032] figure 1 As shown, it is a perspective view of the implemented follow-up sewage tank of the present invention with a cover film sealing cover, figure 2 It is the front view implemented by the present invention, figure 1 , figure 2 As shown in , the sealing cover mainly includes a column 2, a pipe support frame 3, an annular steel rail 4, a steel outer ring 5, a steel inner ring 14, a load-bearing cable 10, a sealing film and an air extraction pipe 9, a steel frame 12 and an air extraction main pipe 16.

[0033] Wherein, the bottom of the sealing cover is a vertical column 2, and the column 2 is usually fixed in the sewage tank 1 and protrudes upward; there is an annular support plate 31 around the column 2, and a plurality of pipe support frames are fixed on the support plate 31 3 (4-12 pipe support frames are generally pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com