Polymer multi-edge pile grouting method

A polymer and grouting technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of inability to meet emergency rescue tasks, high cost of anti-sliding pile technology, slow construction speed, etc. and shear resistance, quick construction and full pile shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

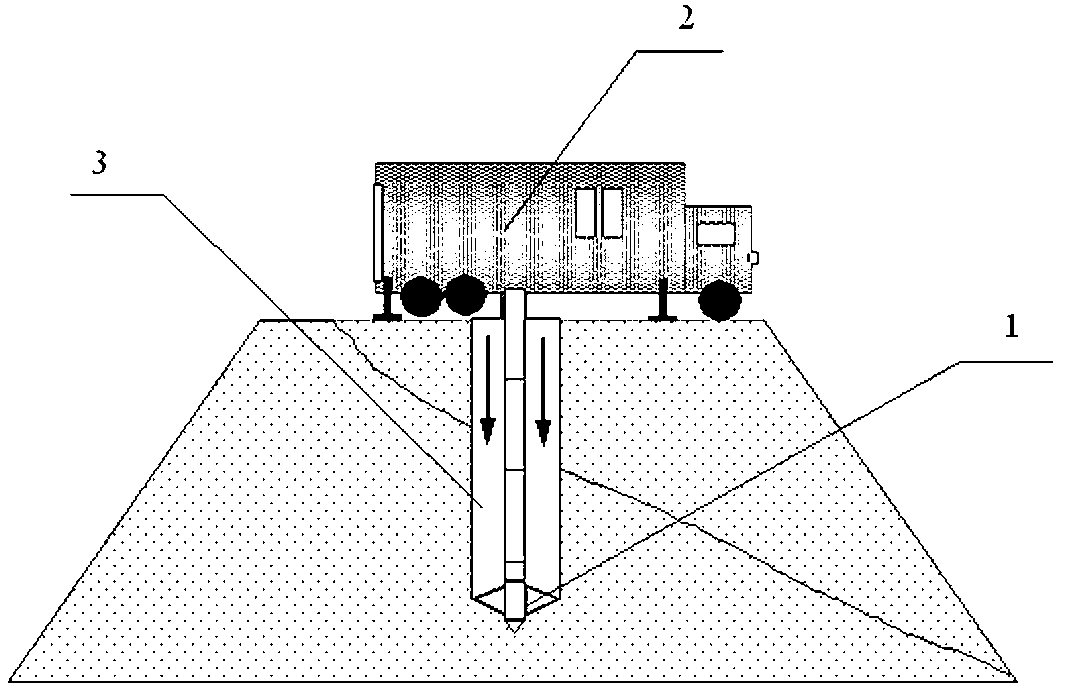

[0042] A grouting method for polymer polygonal piles, the specific implementation steps are as follows:

[0043] (1) Arrangement of pile positions: on the slope to be treated, arrange the pile positions according to the design;

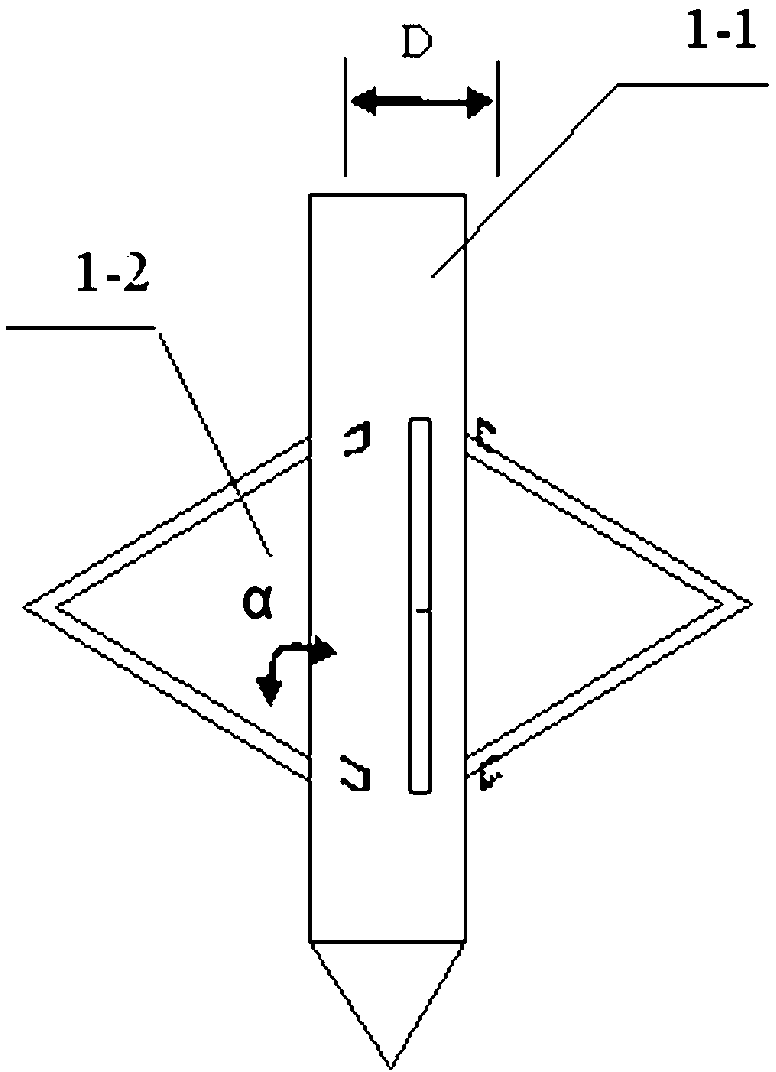

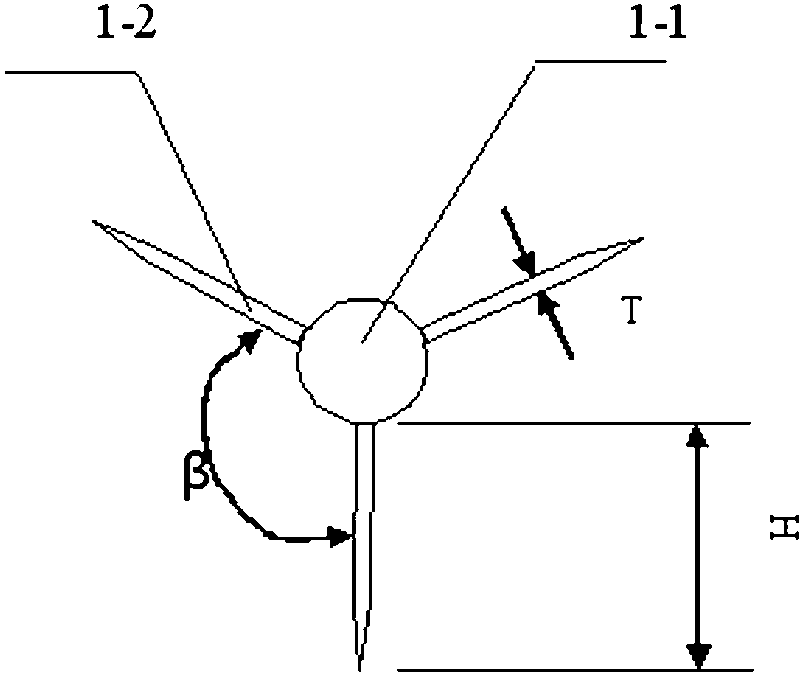

[0044] (2) Make triangular drilling tool, pile position to form hole: make triangular drilling tool 1, triangular drilling tool 1 consists of drill pipe 1-1 and three ribs 1-2 evenly welded on the circumference of drill pipe 1-1 The diameter D of the drill pipe cone probe is 40-80mm, and the diameter D can be 40mm, 50mm, 65mm, 75mm or 80mm, that is, any value between 40-80mm, and the edge is a triangle welded with a cutting edge Steel plate, the edge height H is 100-400mm, the edge height H can be 100mm, 200mm, 350mm or 400mm, that is, any value between 100-400mm, the angle α between the bottom edge of the edge and the drill pipe is 30- 45 degrees, the edge thickness T is 10-30mm, and the angle β between adjacent edges of the triangular drilling tool...

Embodiment 2

[0049] A grouting method for polymer polygonal piles, the specific implementation steps are as follows:

[0050] (1) Arrangement of pile positions: on the slope to be treated, arrange the pile positions according to the design;

[0051] (2) Make a four-sided drilling tool and make a hole at the pile position: make a four-sided drilling tool. The four-sided drilling tool is composed of a drill pipe and four edges uniformly welded on the circumference of the drill pipe. The diameter D of the drill pipe cone probe is 40 -80mm, the diameter D can be 40 mm, 50 mm, 65 mm, 75 mm or 80 mm, that is, any value between 40-80mm; The height H can be 100 mm, 200 mm, 350 mm or 400 mm, that is, any value between 100-400mm, the angle α between the bottom edge of the edge and the drill pipe is 30-45 degrees, and the thickness T of the edge is 10-30mm. The angle between the adjacent edges of the four-sided drilling tool is 90 degrees; according to the designed pile position, at each pile positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com