Concrete prefabricated product for underground construction and production method of product

A concrete and prefabricated technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of affecting work efficiency, increasing the amount of steel, not easy to steel cages, etc., to ensure the quality of piles, ensure the quality of welding, The effect of saving welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The concrete prefabricated product and its production method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

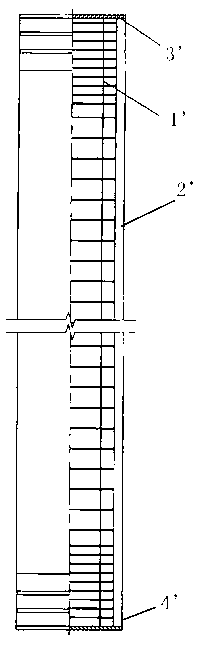

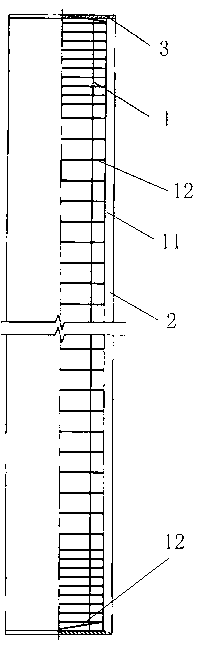

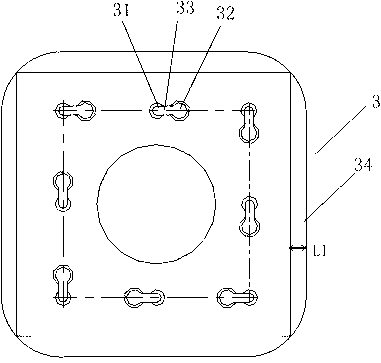

[0053] refer to Figure 2-6 As shown, the concrete prefabricated product of the present invention comprises: reinforcement cage 1 and concrete 2, and reinforcement cage 1 comprises the longitudinal reinforcing bar 11 of longitudinal force and the transverse reinforcing bar 12 of shearing force, and transverse reinforcing bar 12 is spirally wound on longitudinal reinforcing bar 11 and fixed by welding, the two ends of the steel cage 1 are provided with metal end plates 3, and the metal end plates 3 are provided with tapered holes 31 and screw holes 32, between the tapered holes 31 and screw holes 32 There is also a transition groove 33 between them; the longitudinal steel bar 11 is set in the tapered hole 31 and connected with the metal end plate 3, the two ends of the pile body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com