Reinforced culvert

A reinforced, culvert technology, applied in the field of culverts, can solve the problems of inconvenient construction, affecting the construction period, and long construction period, and achieve the effect of reducing steel consumption, saving costs and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

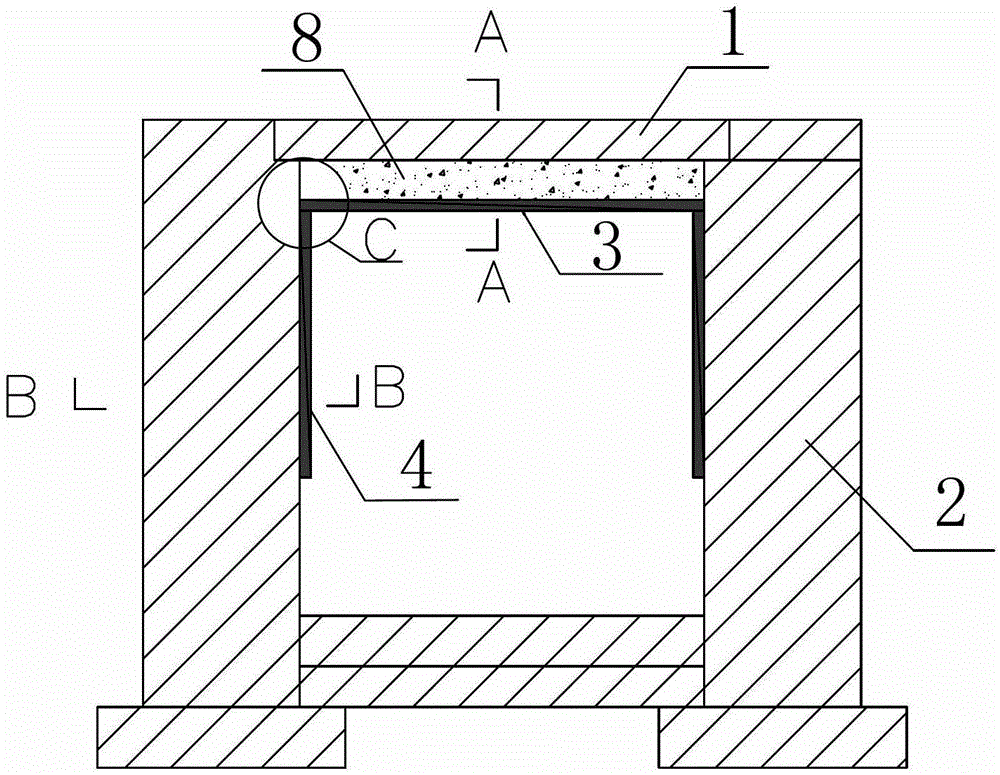

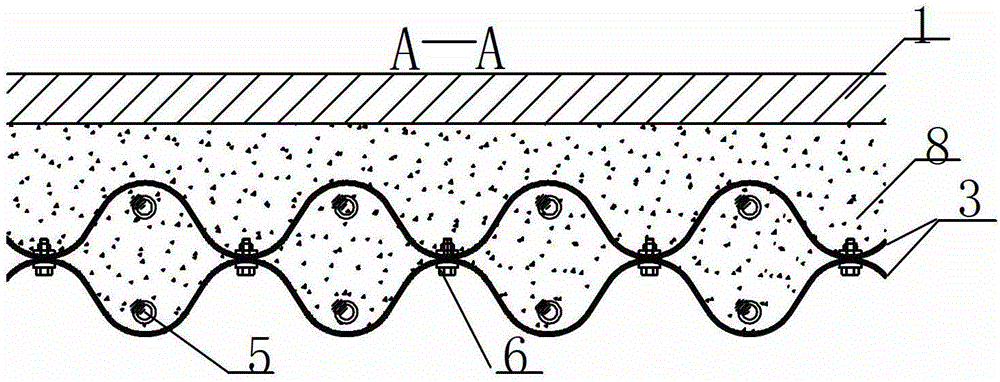

[0012] Such as Figure 1~4 As shown, the hot-rolled steel plate of Q345 or higher grade is selected in the factory in advance and processed into a standard corrugated steel plate according to the drawing, and the finished rolled threaded steel bar 5 with a sheath is placed on the lower corrugated steel plate, and its tensile strength should be greater than 830Mpa, the yield strength should be greater than 730Mpa, after checking that the position of each component is correct, buckle the upper corrugated steel plate on the lower corrugated steel plate and tighten the corrosion-resistant hot-dip galvanized bolt 6, so that several cavity columns are formed between the two corrugated steel plates body, the thickness of the column is generally more than 220mm, that is, the distance from the wave top to the wave top of the two-layer corrugated steel plate, which is twice the wave height of the corrugated steel plate, and the wave distance of the corrugation is generally greater than 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com