Collagen fiber regenerated bark and manufacturing method thereof

A collagen fiber and manufacturing method technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of troublesome process, lack of entanglement, difficult to fully improve the mechanical strength of regenerated skin, etc., to achieve uniform distribution, good strength and feel , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

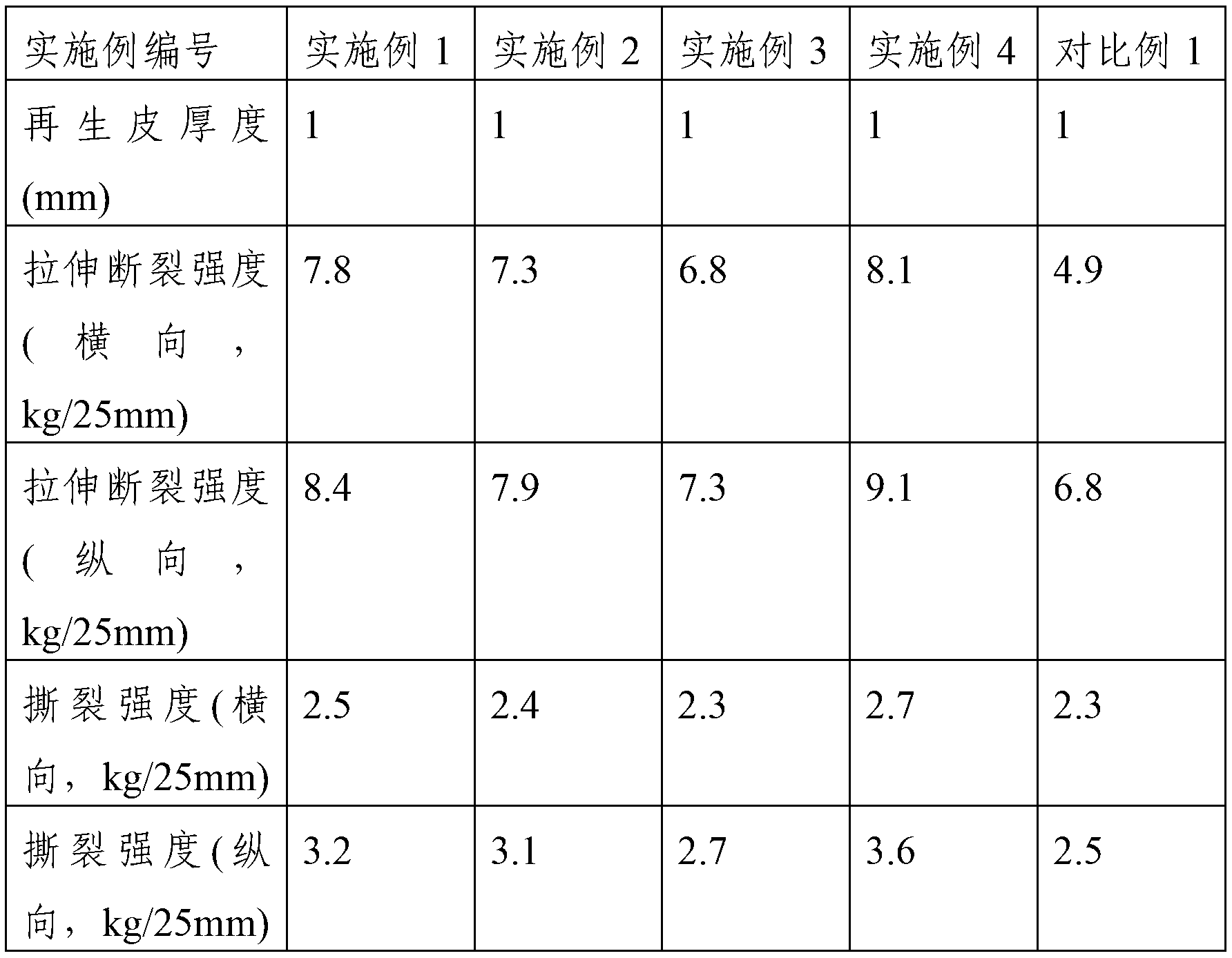

[0039] The invention relates to a collagen fiber regenerated skin, the material composition and weight percentage of the regenerated skin are as follows: 92% of collagen fiber and 8% of hot-melt adhesive fiber. Wherein, the length of the collagen fibers is 1-3 cm. The thickness of the regenerated leather is 0.5-3 mm, the tear strength in both the transverse direction and the longitudinal direction is above 23N, and the tensile strength in the transverse direction and the longitudinal direction are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0040] The present invention also relates to a method for manufacturing the above-mentioned collagen fiber regenerated skin, which comprises the following steps in turn:

[0041] (1) Defibrilation: Defibril the pig, sheep, and cowhide leather to form collagen fibers, wherein the pig, sheep, and cowhide leather are used as scraps for ta...

Embodiment 2

[0051] The invention relates to a collagen fiber regenerated skin, the fiber net material composition and weight percentage of the regenerated skin are: 95% of collagen fiber and 5% of hot-melt adhesive fiber. Wherein, the length of the collagen fibers is 1-3 cm. The thickness of the regenerated leather is 0.5-3 mm, the tear strength in both the transverse direction and the longitudinal direction is above 23N, and the tensile strength in the transverse direction and the longitudinal direction are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0052] The present invention also relates to a method for manufacturing the above-mentioned collagen fiber regenerated skin, which comprises the following steps in turn:

[0053] (1) Defibrilation: Defibril the pig, sheep, and cowhide leather to form collagen fibers, wherein the pig, sheep, and cowhide leather are used as scraps for tanni...

Embodiment 3

[0063] The invention relates to a collagen fiber regenerated skin, the material composition and weight percentage of the fiber net of the regenerated skin are: 99% of collagen fiber and 1% of hot-melt adhesive fiber. Wherein, the length of the collagen fibers is 1-3 cm. The thickness of the regenerated leather is 0.5-3 mm, the tear strength in both the transverse direction and the longitudinal direction is above 23N, and the tensile strength in the transverse direction and the longitudinal direction are both above 68N. Among them, taking the performance of regenerated leather with a thickness of 1 mm as an example, the results are shown in Table 1.

[0064] The present invention also relates to a method for producing the above-mentioned collagen fiber regenerated leather, which includes the following steps in sequence: (1) Defibrilating: Defibrilating pig, sheep, and cowhide leather to form collagen fibers, wherein the pig, sheep, and cowhide leather is Cuttings for tanning. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com