Ultra-wear-resistant alumina ceramic ball and preparation method thereof

A kind of alumina ceramics, super wear-resistant technology, applied in the field of super wear-resistant alumina ceramic balls and its preparation, can solve the problems of high wear of alumina ceramic balls, and achieve the effect of superior wear, high value and creative meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

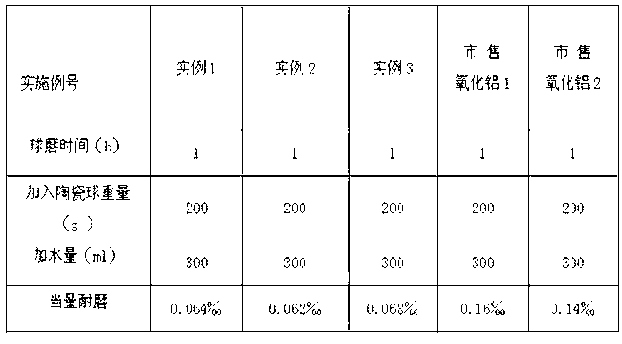

Embodiment 1

[0020] Embodiment 1: alumina powder 90%, kaolin 7%, talc 0.7%, TZP 2%, rare earth (La 2 o 3 / Y 2 o 3 ) 0.3%

[0021] 1. Practicing mud

[0022] ①Put the raw material mixture and water into the ball mill according to the proportion, and run for 20 hours to release the pulp;

[0023] ② After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0024] ③ After passing through the iron removal tank, the slurry is pumped to the mud press by the pump to dehydrate the slurry to make mud cake;

[0025] 2. Drying: Send the prepared mud cake into the drying room and dry at 45°C until the moisture content is 3%;

[0026] 3. Calcination synthesis: Send the dried mud cake into the kiln for calcination synthesis at 1450°C;

[0027] 4. Ball milling: put the calcined semi-finished product into a ball mill for grinding;

[0028] 5. Granulation: Send the ground slu...

Embodiment 2

[0031] Embodiment 2: alumina powder 92%, kaolin 6%, talc 0.5%, TZP 1.2%, rare earth (La 2 o 3 / Y 2 o 3 ) 0.3%

[0032] 1. Practicing mud

[0033] ①Put the raw material mixture and water into the ball mill according to the proportion, and run for 22 hours to release the pulp;

[0034] ② After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0035] ③ After passing through the iron removal tank, the slurry is pumped to the mud press by the pump to dehydrate the slurry to make mud cake;

[0036] 2. Drying: Send the prepared mud cake into the drying room and dry it at 50°C until the water content is 3%;

[0037] 3. Calcination synthesis: Send the dried mud cake into the kiln for calcination synthesis at 1500 °C;

[0038] 4. Ball milling: put the calcined semi-finished product into a ball mill for grinding;

[0039] 5. Granulation: Send the ground ...

Embodiment 3

[0042] Embodiment 3: alumina powder 94%, kaolin 4%, talc 0.5%, TZP 1.4%, rare earth (La 2 o 3 / Y 2 o 3 ) 0.1 %

[0043] 1. Practicing mud

[0044] ①Put the raw material mixture and water into the ball mill according to the proportion, and run for 25 hours to release the pulp;

[0045] ② After the mud enters the tank, start the mixer and the pumping machine, filter it through the vibrating screen, and flow into the iron removal tank at the same time;

[0046] ③ After passing through the iron removal tank, the slurry is pumped to the mud press by the pump to dehydrate the slurry to make mud cake;

[0047] 2. Drying: Send the prepared mud cake into the drying room and dry it at 48°C until the moisture content is 3%;

[0048] 3. Calcination synthesis: Send the dried mud cake into the kiln for calcination synthesis at 1550 °C;

[0049] 4. Ball milling: put the calcined semi-finished product into a ball mill for grinding;

[0050] 5. Granulation: Send the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com