Environmental protection dredging stockyard sediment original position rapid dehydration system

A rapid dehydration and environmental protection dredging technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor interfacial adhesion of cement slurry, easy to be affected by weather conditions, long construction period, etc. The effect of shortening drying time and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

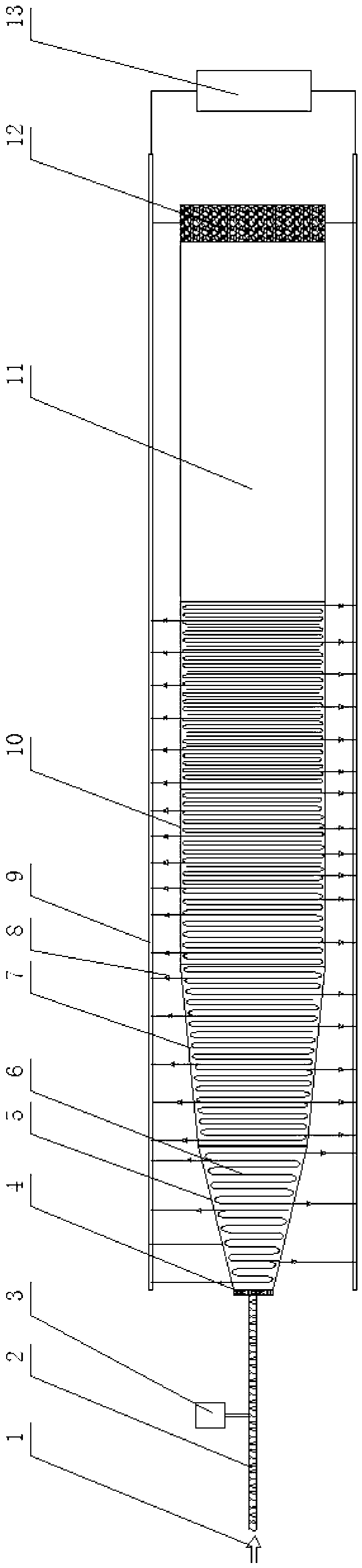

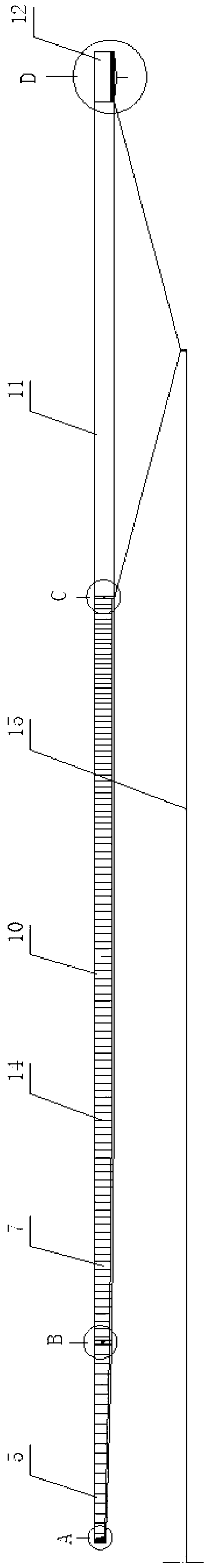

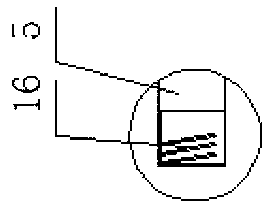

[0031] An in-situ rapid dehydration system for bottom sludge in an environmentally friendly dredging yard, including an input unit, a grid unit 4, a positive pressure suction filtration drainage unit, an overflow mud sedimentation unit 11, a residual water purification unit 12, and a residual water discharge unit 13. The individual units are connected sequentially. The structure of each unit is described below:

[0032] 1. The input unit is composed of an input pipeline 1, a turbulent flow disturbance pipeline 2 and a dosing unit 3. The input pipeline transports dredging mud with a high water content to the turbulent flow disturbance pipeline, and the turbulent flow disturbance pipeline is installed with a The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com