Roof eaves board

A technology of roof panels and thermal insulation panels, applied to roofs, roof cladding, and roofs using flat/curved panels, etc., can solve problems such as high cost, trouble, heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

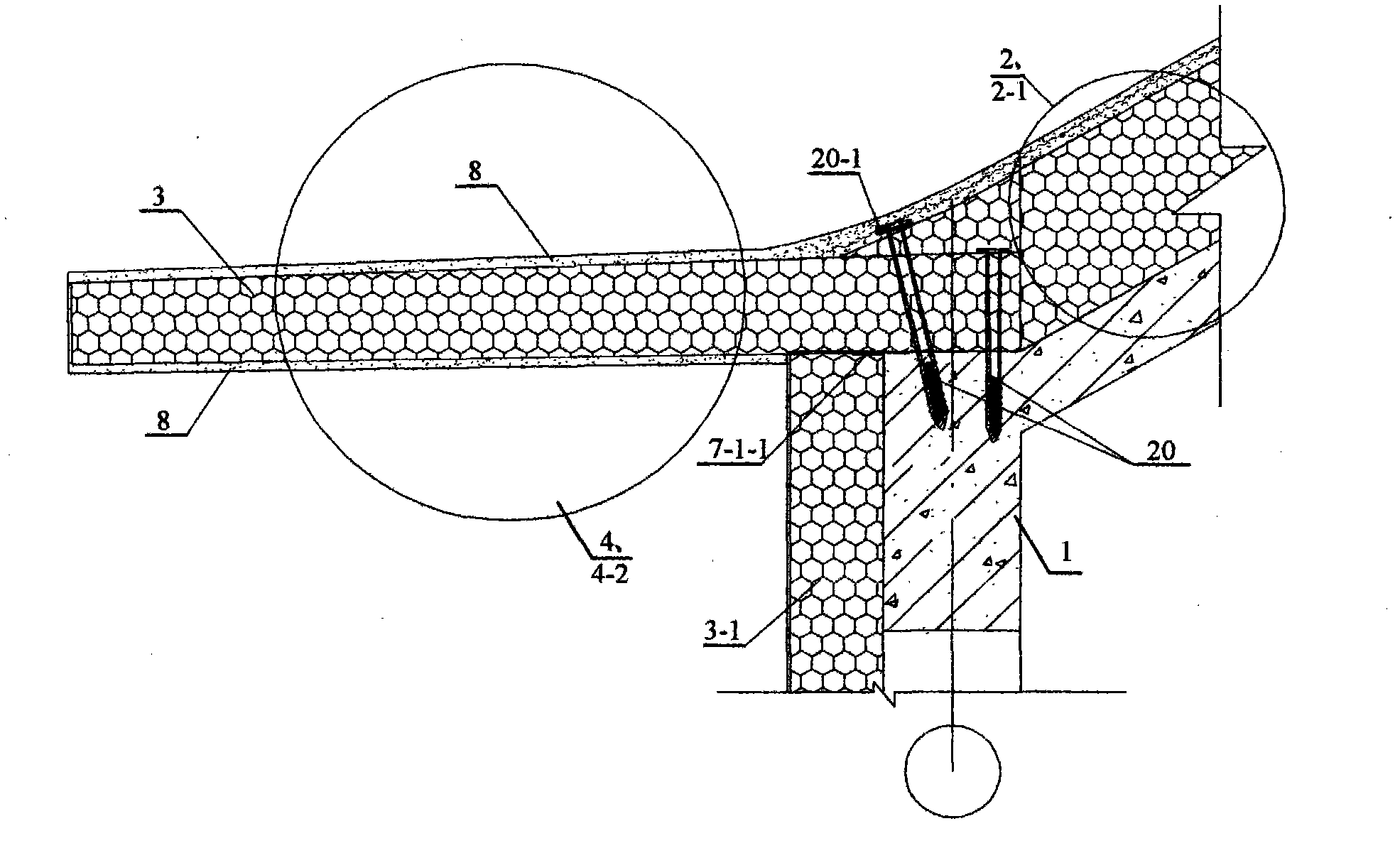

[0075] Implementation mode one: see Figure 1 to Figure 14 , A roof eaves on this embodiment, which consists of an outer wall load -bearing component 1. The roof and the roof 2, the roof eaves 4; ; The load-bearing member 1 of the external wall is a load-bearing external wall, a concrete beam, a steel beam;

[0076] The roof eaves 4 is different from the slope of the roof panel 2. The slope of the roof panel 2 is greater than the slope 4 of the roof eaves 4; when the roof panel 2 is arc or folded (can be placed at the folding line to be arc), from the from the folding line), from the from the folding line), from the from the folding line), from The slope of the upper end of the roof panel 2 to the lower end is greater than the slope of the roof eaves 4. The slope of the opposite direction (that is, the roof eaves upper plate); the formation of a roof -type roof eaves is formed; The slope formed at the end; the roof eaves and roof panels of the eaves-type roof molding have th...

Embodiment approach 2

[0084] Implementation mode two: see Figure 17 The difference between this embodiment and Embodiment 1 is that this embodiment adds a cantilever beam 1-1, the cantilever beam 1-1 is anchored to the load-bearing member 1 of the outer wall, and the roof cornice 4 is fixed to the cantilever beam 1-1 ; or a connecting beam 1-2 is also provided on the cantilever beam 1-1, and the roof eaves board 4 is also fixed with the connecting beam 1-2; Coupling beams are arranged, and the roof eaves board 4 is also fixed with the coupling beams on the outer eaves porch columns.

[0085] When the width of the roof eaves is large, it is necessary to install the roof eaves according to this embodiment, and a support for the roof eaves is also provided outside the load-bearing member of the outer wall. Large public buildings and monastery buildings often need to set up outer eaves and colonnades. The cantilever beam 1-1 and the connecting beam 1-2 are preferably made of light heat-insulating ma...

Embodiment approach 3

[0086] Embodiment 3: A roof cornice in this embodiment. In this embodiment, the corner cornice at the sloping ridge of the roof corner is upturned to form a cornice-shaped structure of the corner ridge. The corner cornice is a light thermal insulation Corner eaves, or concrete corner eaves; the roof eaves are cornice-shaped, or obliquely straight-line shaped.

[0087] During construction, it is necessary to enlarge the sample when it is close to the corner of the house, gradually increase the elevation, and form an upturned cornice shape at the corner of the house. In many buildings with large roofs, cornices are formed only at the corner ridges, while the cornices other than the corners are oblique and straight, and the shape is also beautiful. The big roof building has the top of the mountain, the top of the mountain, the top of the mountain, the top of the roof, and the top of the mountain. The present invention can realize these big roof structures with structural measures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com