Strip direct splicing device

A splicing device and strip material technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of high cost, poor reliability of the whole machine, small parts cannot be separated, etc., and achieve high degree of automation and high pressure. The effect of reliable connection and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

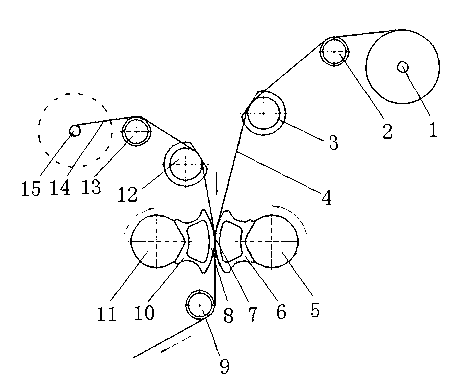

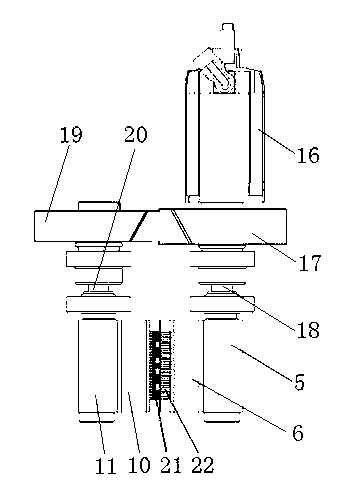

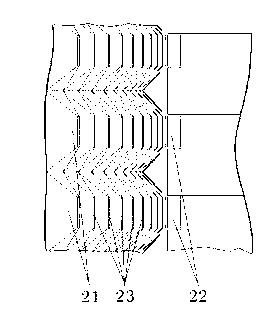

[0013] The present invention will be further described below with reference to the accompanying drawings.

[0014] The device for direct splicing of strips provided by the present invention includes new and old tape roll support mechanisms, and is characterized in that a crimping mechanism is provided between the new and old tape roll support mechanisms, and the crimping mechanism includes a roller 11 provided with a punch 10 and a crimping mechanism. The roll 5 of the concave die 6 is set, the new strip 4 and the old strip 14 are placed between the punch 10 of the roll 11 and the concave die 6 of the roll 5, the roll shaft 20 of the roll 11 is provided with a gear 19, and the roll 5 The roller shaft 18 is provided with gears 17, 19 and 17 which mesh with two gears, wherein the axle of the gear 17 is connected with the main shaft of the power motor 16 to drive the roller pairs 11 and 5 to rotate in opposite directions through the power motor 16, the gears 19 and 17, The new st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com