A keeping unit and a line drawing device

A technology of scribing device and holder, which is applied to glass cutting devices, fine working devices, manufacturing tools, etc., can solve problems such as poor rotation of bearings and poor movement of holders, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

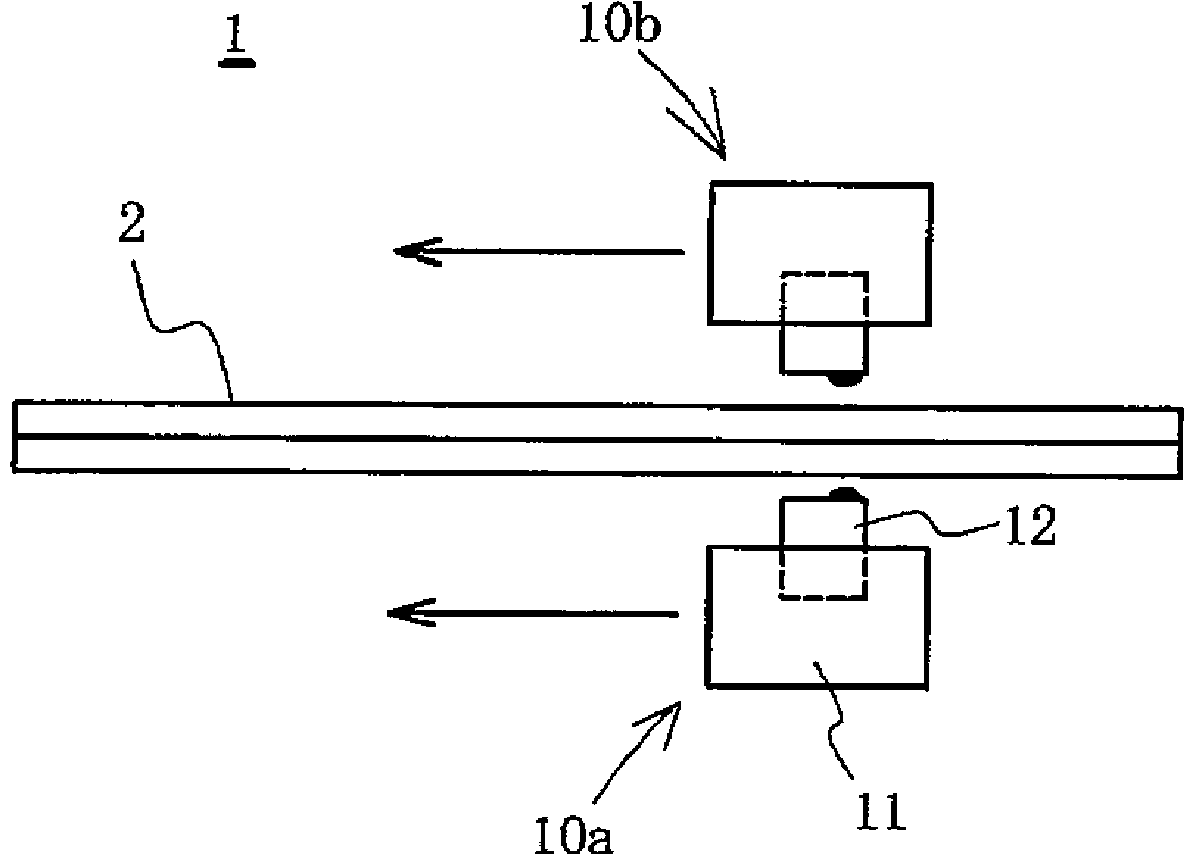

[0064] figure 1 A schematic diagram of the scribing device 1 according to the embodiment of the present invention is shown in . The scribing device 1 includes a support unit (not shown) that supports a brittle material substrate 2 such as a glass-bonded substrate such as a liquid crystal panel in advance. Furthermore, a scribing head 10 a is provided movably on the lower surface side of the brittle material substrate 2 , and a scribing head 10 b is movably provided on the upper surface side.

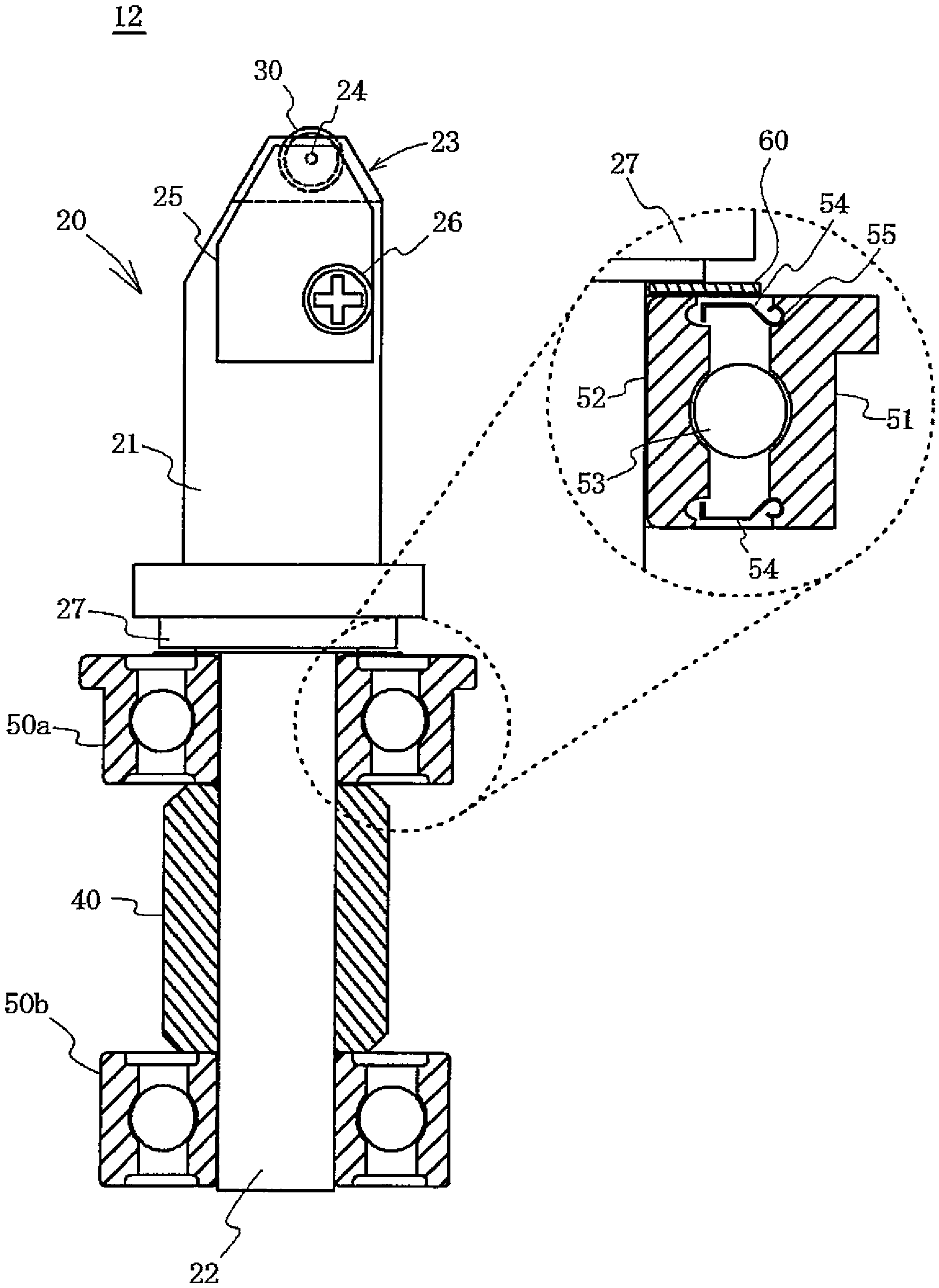

[0065] The scribing head 10 a includes a main body 11 and a holder unit 12 mounted on the main body 11 . In addition, details about the holder unit 12 will be described later. In addition, since the scribing head 10b has the same structure as the scribing head 10a, description is abbreviate|omitted.

[0066] In addition, although not particularly shown in the figure, the scribing device 1 includes an elevating mechanism for moving the scribing heads 10a, 10b closer to or away from th...

Embodiment approach 2

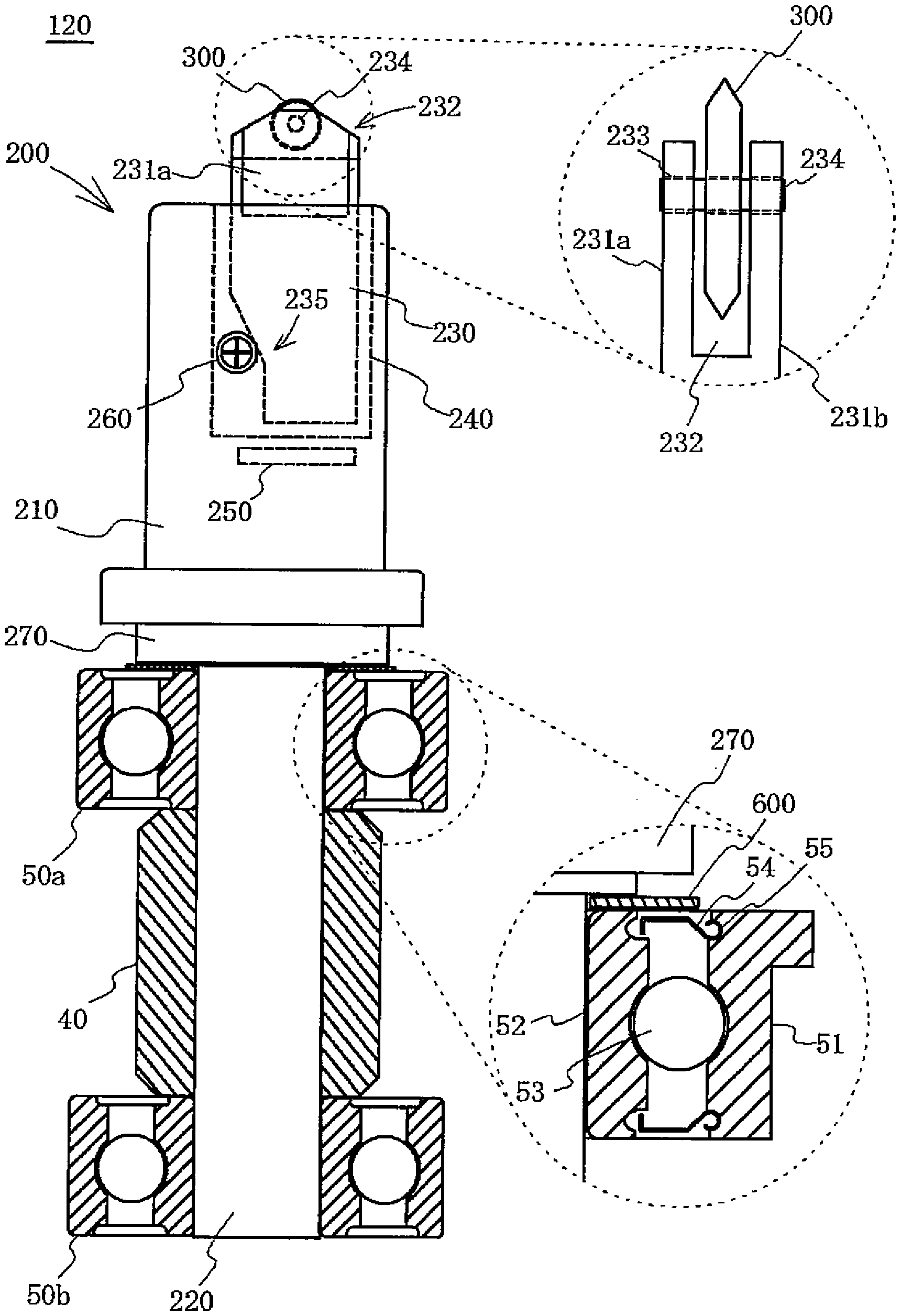

[0084] Like the scribing device 1 of Embodiment 1, the scribing device according to the embodiment of the present invention includes a scribing head on the lower surface side and the upper surface side of the brittle material substrate, respectively. Furthermore, holder units are respectively attached to the main body of the scribing head. image 3 The shown holder unit 120 is different in configuration from the holder unit 12 of the first embodiment. In addition, the same code|symbol is used about the same structure as the holder unit 12 of Embodiment 1, and description is abbreviate|omitted suitably.

[0085] The holder unit 120 includes a scribing wheel 300 , a holder 230 rotatably holding the scribing wheel 300 , and a cylindrical holder joint 200 including two bearings 50 a , 50 b and a cylindrical spacer 40 . in addition, image 3 A front view of the holder unit 120 is shown, and a cross-sectional view of the bearings 50a, 50b, and the spacer 40 is shown.

[0086] A h...

Embodiment approach 3

[0100] Next, Embodiment 3 will be described. Embodiment 3 is a holder unit 12a obtained by partially improving the holder unit 12 described in Embodiment 1. As shown in FIG. In addition, about the holder unit 12a, the same code|symbol is used for the same structure as the holder unit 12, and description is abbreviate|omitted. Figure 4 A front view of the holder unit 12a according to Embodiment 3 is shown in , and a cross-sectional view of the bearings 50a, 50b and the spacer 40 is shown.

[0101] The holder unit 12 a differs from the holder unit 12 in that a cylindrical cover 28 is attached to the outer periphery of the cylindrical portion of the wheel holding portion 21 . The cover 28 is a member formed of metal such as aluminum or resin, and has a size to cover the entire upper surface of the bearing 50a. By using this holder unit 12a, the gap between the main body 11 and the holder unit 12a can be made smaller than when the holder unit 12 without the cover 28 is used. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com