Binary compound filter rod for tobacco as well as processing method and equipment thereof

A dual-composite, composite rod technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problems of harming the legitimate rights and interests of consumers, harming consumers, and loss of national interests, so as to avoid losses of national interests and reduce harmful effects. Substances, the effect of protecting legitimate interests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

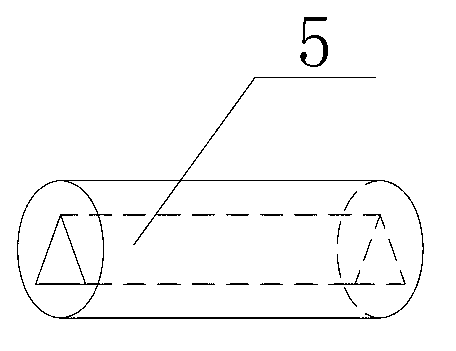

[0033] Such as Figure 1-8 As shown, the binary composite filter stick for cigarettes in this embodiment is composed of acetate fiber and activated carbon hollow filter rod binary composite unit 1, outer wrapping layer 2 and inner wrapping layer 3; said acetate fiber and activated carbon hollow filter The rod binary composite unit 1 is a round rod-shaped body composed of cellulose acetate filter rod segments 4 and activated carbon hollow filter rod segments 5; the inner wrapping layer 3 is wrapped on the cellulose acetate filter rod segments 4; the outer The wrapping layer 2 is wrapped on the inner wrapping layer 3 and the activated carbon hollow filter stick section 5; the activated carbon hollow filter stick section 5 is manufactured by bonding and shaping the granular activated carbon, A cylinder with a columnar cavity inside. The internal columnar cavity cross-section of the activated carbon hollow filter rod section 5 can be designed in various shapes such as circle, tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com