Rock nori processed product and preparing method thereof

A manufacturing method and a technology for processed products, which are applied in the field of rock seaweed processed products and their manufacture, can solve the problems of not fully reflecting the brittle nature of seaweed, insufficient brittle taste, and easy peeling, so as to prevent flavor deterioration, increase brittleness, short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] A processed product of rock seaweed, dry seaweed with a whole piece weight of 1300g; 800g of corn oil needs to be coated on it; 40g of sugar; 50g of pepper powder; 200g of shiitake mushroom powder; , take another 45g of table salt with a particle size of 60-80 mesh, and spray the seasoning liquid and salt evenly on the surface of the dried seaweed. assimilate into. .

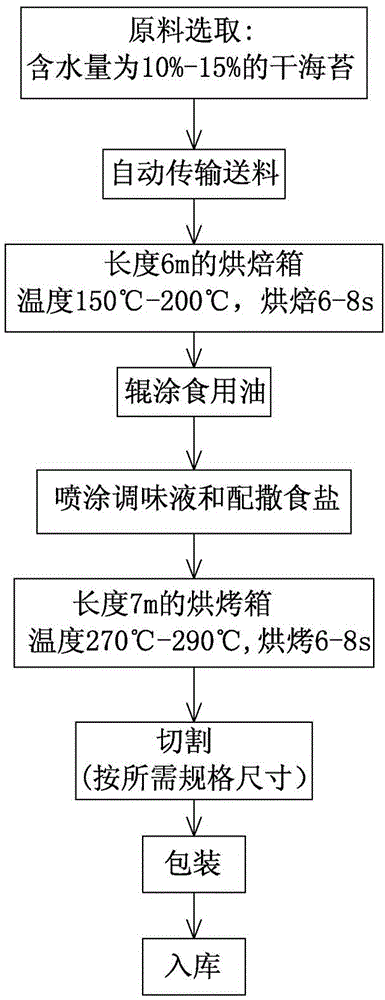

[0016] Such as figure 1 Shown, a kind of manufacture method of rock laver processed product comprises the following steps:

[0017] a. Select dry seaweed with a water content of 10%-15%, and take 1300g parts by weight, and send it into a baking box with a length of 6m, set the baking temperature to 150°C-200°C, and the transmission speed to be 0.8m / s, thereby After 6-8s of transmission and baking, the water content of the dried seaweed is reduced to 3%-5%, and a unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com