Automatic patching machine

An automatic placement machine and frame technology, applied in the direction of electrical components, electrical components, etc., can solve the limitation of component manufacturers' shipments and cost control, production efficiency cannot meet large-scale integrated production, procurement costs and High maintenance costs and other issues, to achieve the effect of reducing equipment procurement costs, occupying a small space, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

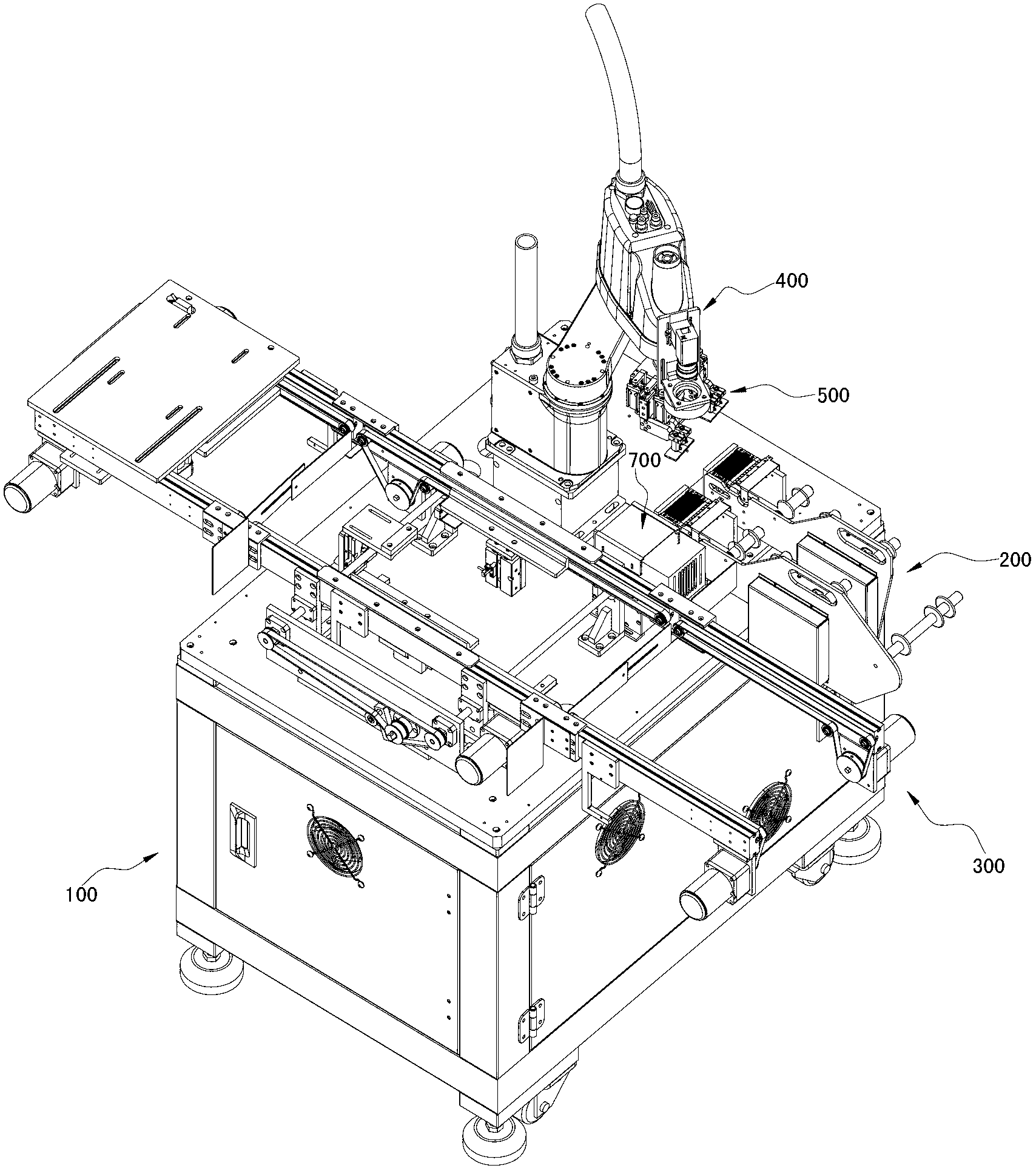

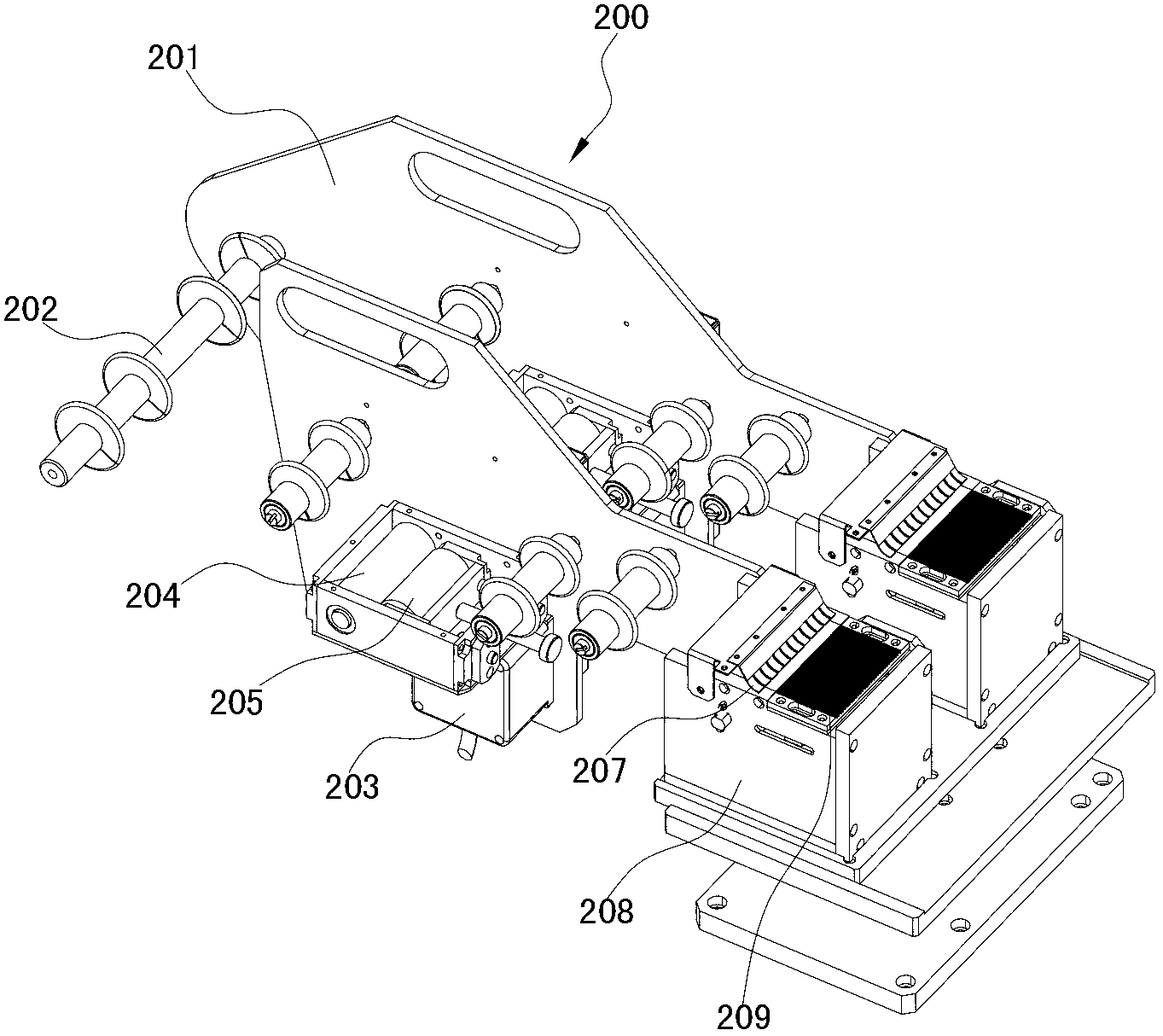

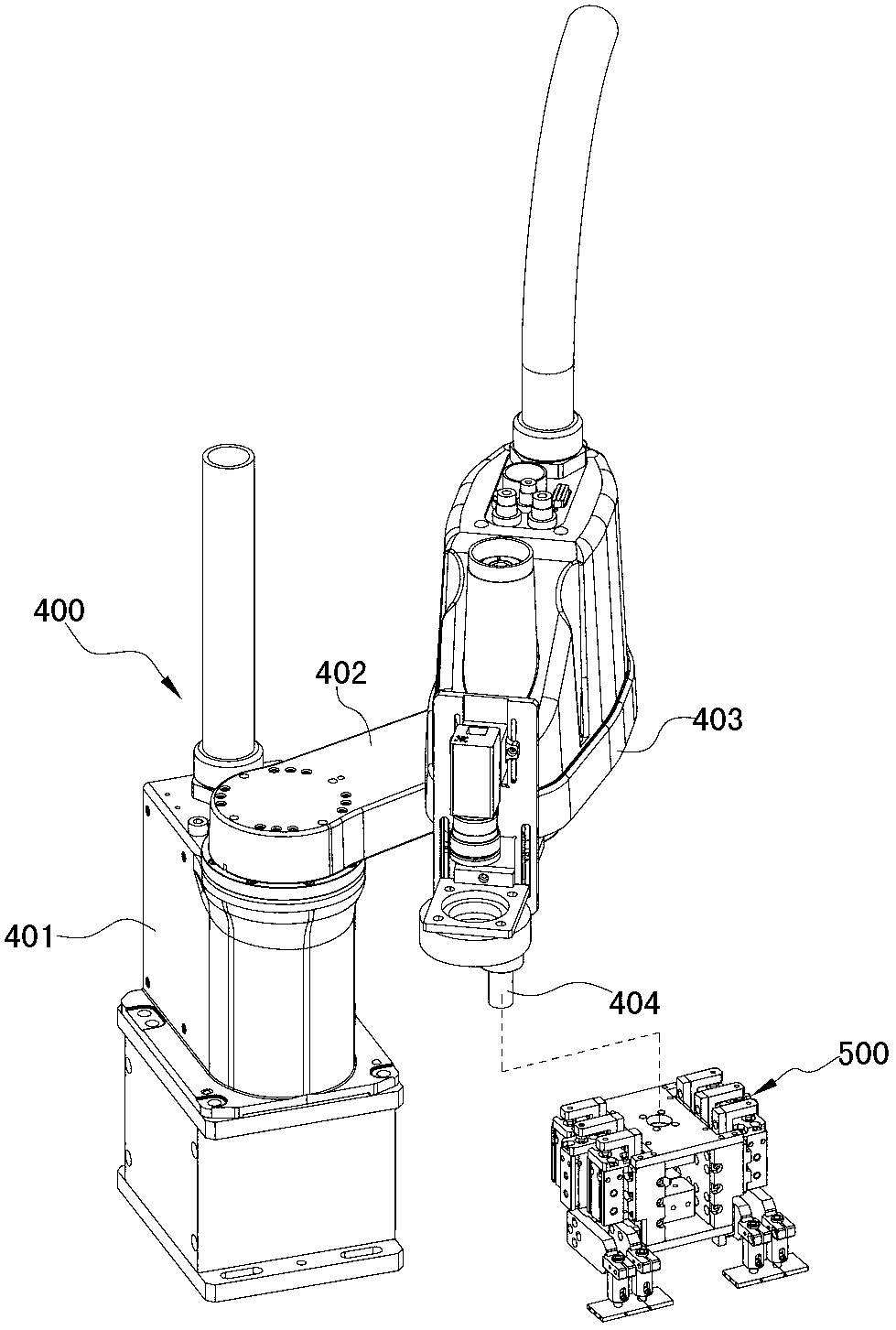

[0032] see figure 1 , 2 , 3, 4, 5, the automatic placement machine of the present invention includes a frame 100, and a conveying assembly 300, a feeding assembly 200, and a manipulator 400 installed on the table top of the rack 100; the conveying assembly 300 is used to convey the object to be pasted, It includes a loading buffer station 310, a bonding station 320, and a discharging buffer station 330 in sequence along the conveying direction. The bonding station 320 is used for placement operation, and the discharge buffer station 330 is used for unloading. The loading buffer station 310, lamination station 320, and discharge buffer station 330 are all independent delivery units. Conveyor assembly 300 comprises the transmission frame that is installed on the frame 100, is respectively provided with a first transmission belt 311 extending along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com