Fiber bragg grating measurement system and method for cylindrical structure thermal diffusivity

A fiber grating and measurement system technology, applied in the field of material thermophysical parameter measurement, can solve problems such as high requirements for experimental environment and conditions, and achieve the effects of good work reliability, strong versatility, and improved result accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

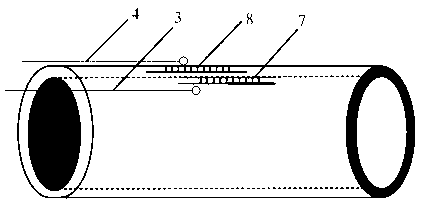

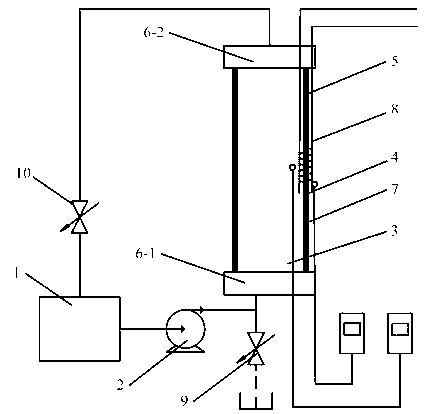

[0039] The measurement system of the present invention is composed of a heating water tank, a water pump, a thermocouple, a cylinder structure to be measured, a thermal insulation sealing material, an optical fiber grating sensor, an optical fiber grating demodulator, and a control valve.

[0040] Among them, the heating water tank, the water pump, and the cylinder to be tested are connected with water pipes, and the control valve is located between the cylinder to be tested and the heating water tank to control the speed of the water flow; the water pump is located between the heating water tank and the cylinder to be tested, and its function It is to inject the water in the heating water tank into the cylindrical structure and maintain dynamic circulation; the water pipe is combined with the thermal insulation sealing material to communicate with the cylindrical structure to be tested; the fiber gratings are respectively fixed on the inner and outer walls of the structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com