Industrial water cooling device

A cold water device, industrial technology, applied in the direction of household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of high failure rate, high cost, complex structure, etc., and achieve low environmental pollution, low purchase and use costs, The effect of large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Industrial chillers are usually divided into water-cooled and air-cooled. The air-cooled chiller uses air as the medium of heat exchange, and the heat is taken away through the air. Compared with water-cooled chillers, air-cooled chillers do not need to install cooling towers, are suitable for water shortage conditions, and are easy to install and move. The industrial cold water device of the present invention belongs to the air-cooled type.

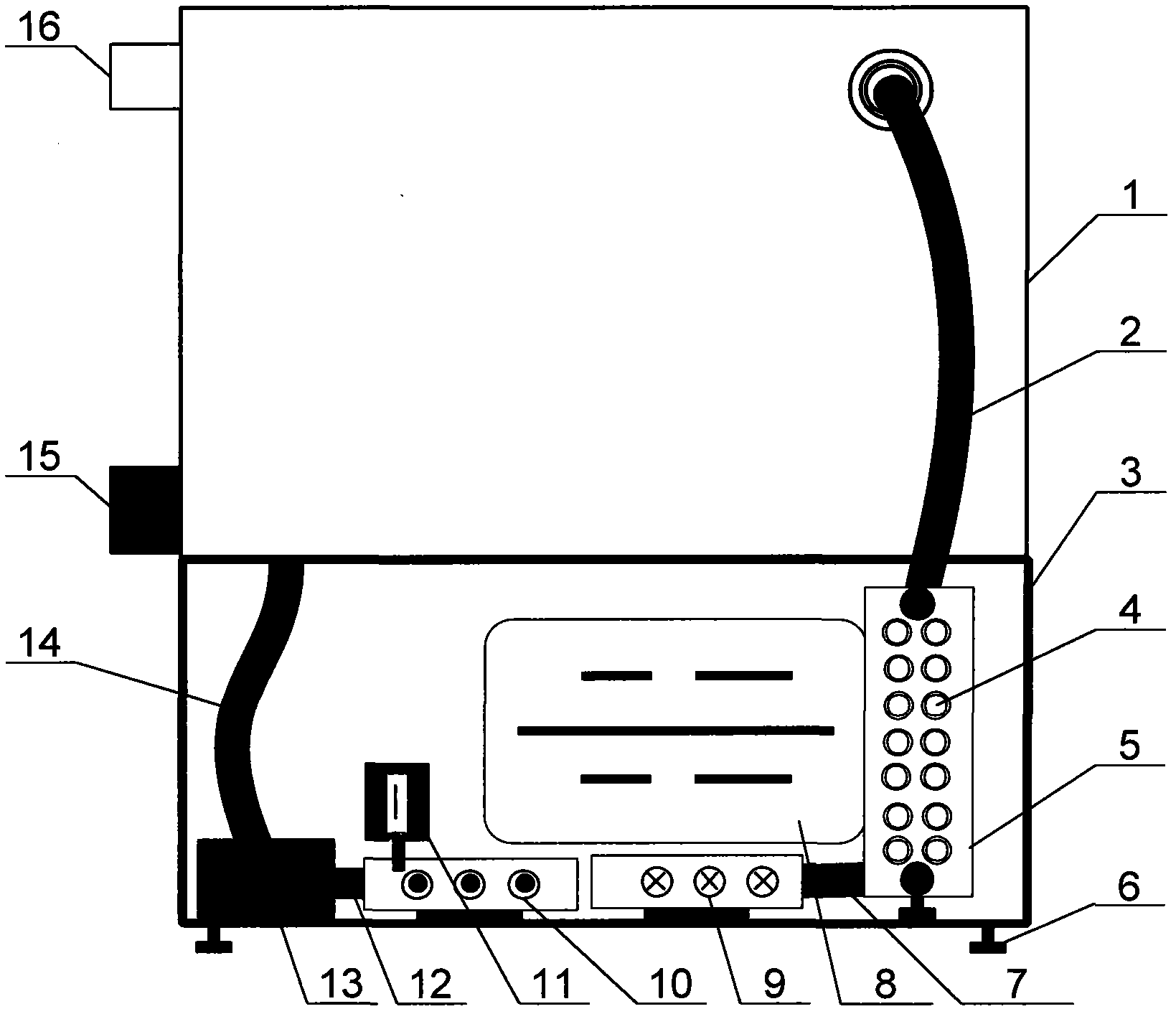

[0019] Such as figure 1 As shown, the industrial cold water device of the present invention includes: a water tank 1, a radiator 5, a blower 8, a return water station 9, a water outlet station 10, a water temperature and pressure gauge 11, and a self-priming pipeline pump 13. The water inlet of the self-priming pipeline pump (13) is connected to the water tank (1) through a water outlet hose (14), and the water outlet of the water pump is connected to the water outlet station (10) through a connecting pipe (12) to supply water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com