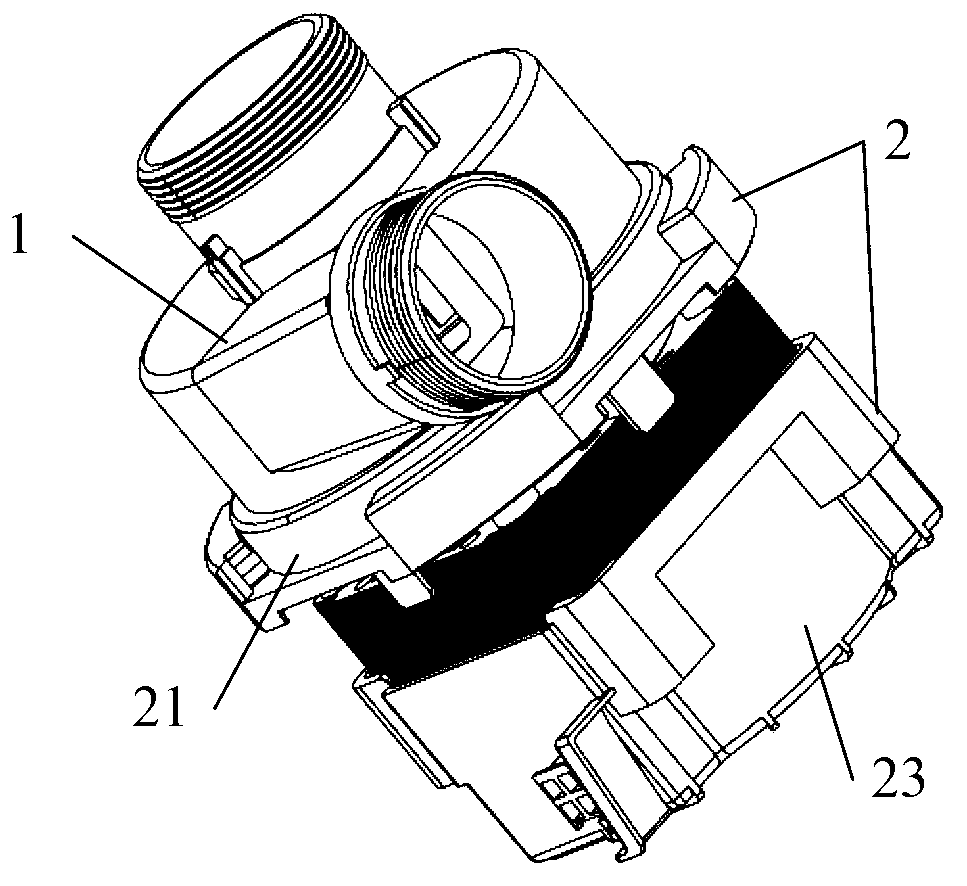

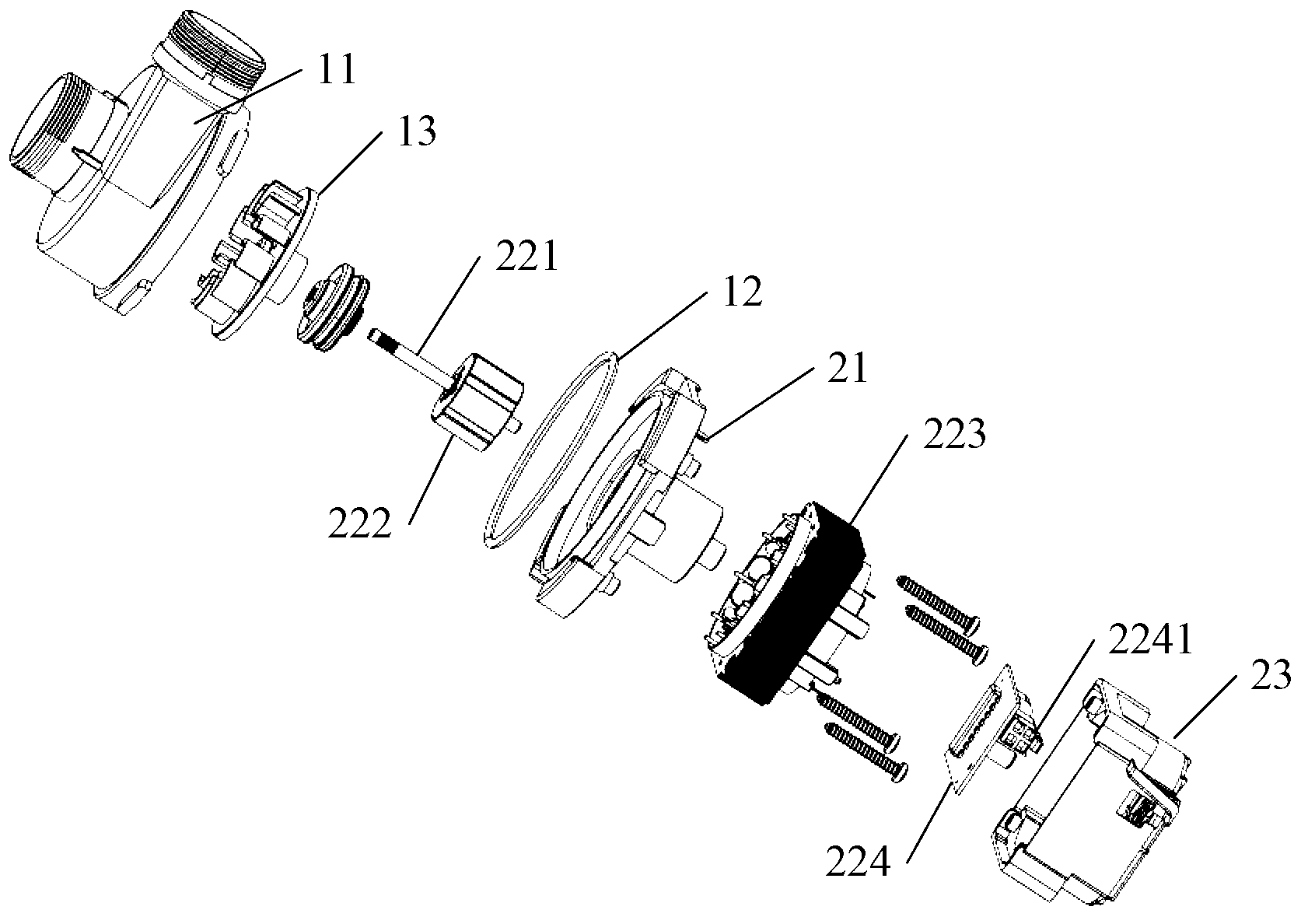

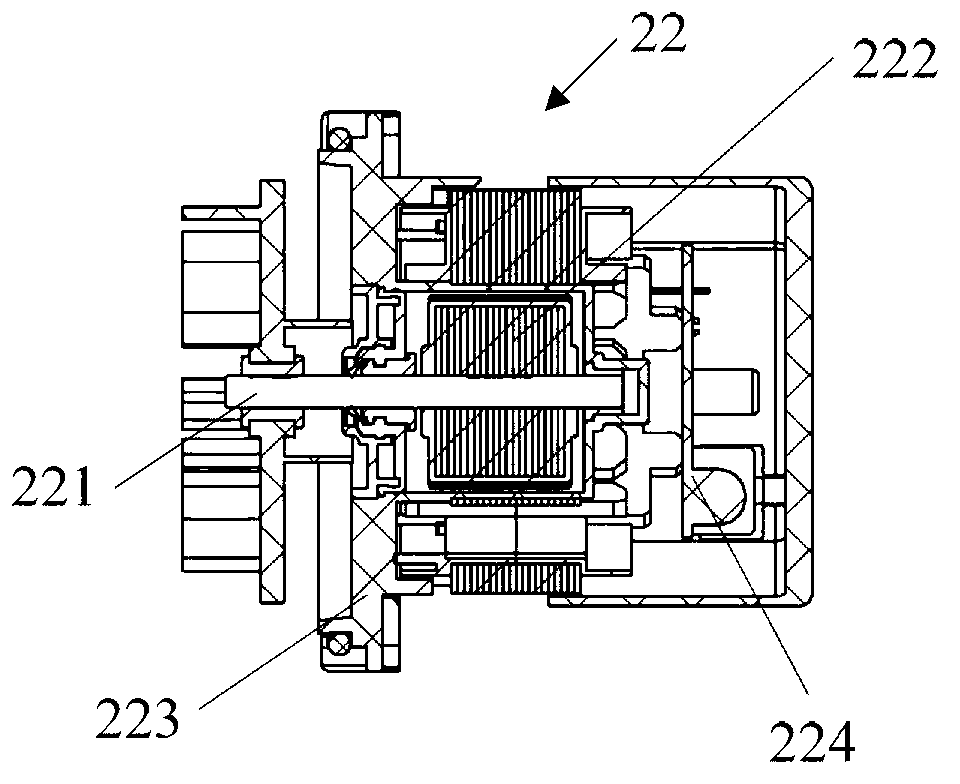

Draining pump

A technology of drainage pump and impeller, applied in the direction of pump, pump device, pump element, etc., can solve the problems of pump shaft resistance, low efficiency of induction motor, high starting noise, etc., to ensure reliability and safety, and simple and easy structure design. performance, prolonging working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Various embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted. It should be understood that the terms "upper", "lower", "upward", "downward" and other directional terms refer to the description of the orientation shown in the drawings, and these orientations are not limiting. If not specifically stated, the terms "inward", "outward", "inner", "outer", "inner" and "outer" herein refer to the range relative to the center of the component, for example, with reference to the axis of the motor, Inner and inner refer to positions or orientations closer to or toward the motor axis, outer and outer refer to orientations or orientations further away from the motor axis, and for each position on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com