Method for cleaning cylinder barrel of lengthened oil cylinder and full-automatic rotating deep-hole tubular cleaning machine

A cleaning machine and cylinder technology, which is applied to cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of poor cleanliness, low efficiency, and inability of cleaning liquid to flow out quickly in manual cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

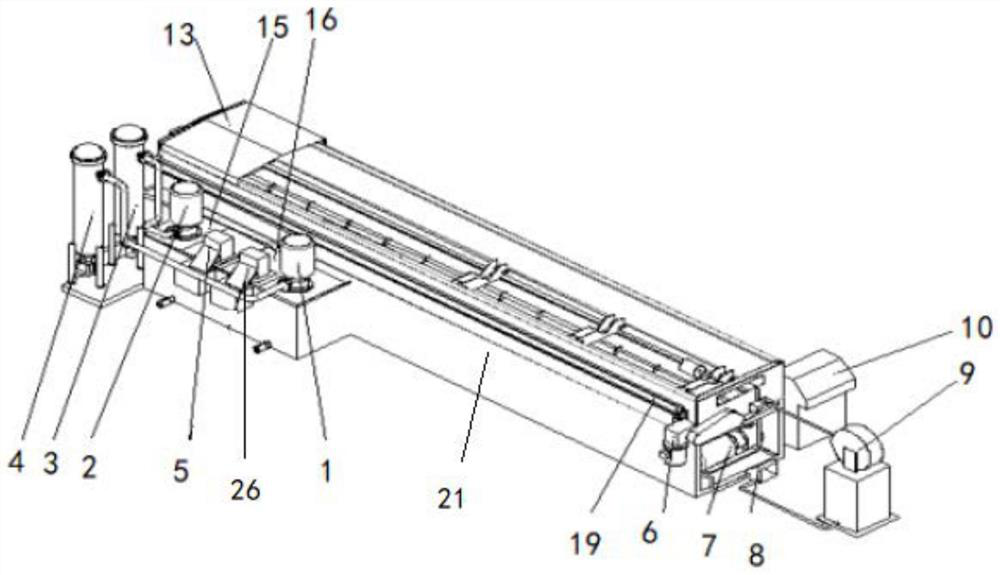

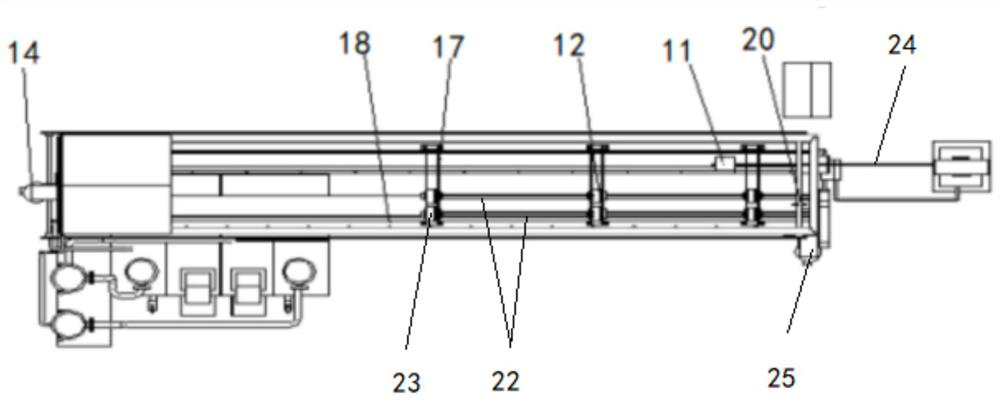

Image

Examples

Embodiment Construction

[0022] It should be noted that the terms "front", "rear", "left" and "right" used in the present invention to represent directions refer to the top view of the present invention ( figure 2 ) in "front", "back", "left", "right"

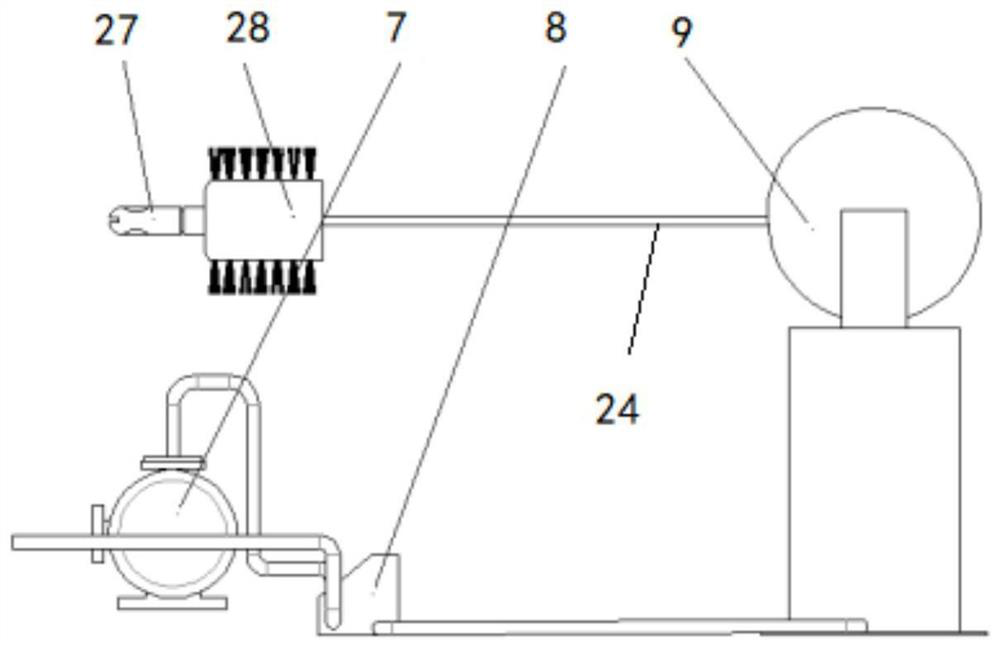

[0023] The cleaning method of the lengthened oil cylinder of the present invention is to spray the cleaning solution to rinse the outside of the cylinder through the spray head, and the spiral nozzle to spray the cleaning solution to rinse the inside of the cylinder; 360-degree fine cleaning without dead angle is carried out inside the cylinder. Specifically, the cleaning method of the extended oil cylinder includes the following steps:

[0024] (1) After the power is turned on, the cylinder rotates on the cleaning station, and the protective cover of the cleaning station is closed;

[0025] (2) The nozzle sprays the cleaning liquid to the outer wall of the cylinder. After spraying and cleaning for 1-2 minutes, the inner hole cleaning pipeline is au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com